Method for preparing to-be-repaired skull flap by 3D printing

A 3D printing and bone flap technology, applied in 3D modeling, bone implants, medical science, etc., can solve the problems of insufficient strength, poor heat preservation, high cost, etc., and achieve beautiful appearance, high safety and reliability , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

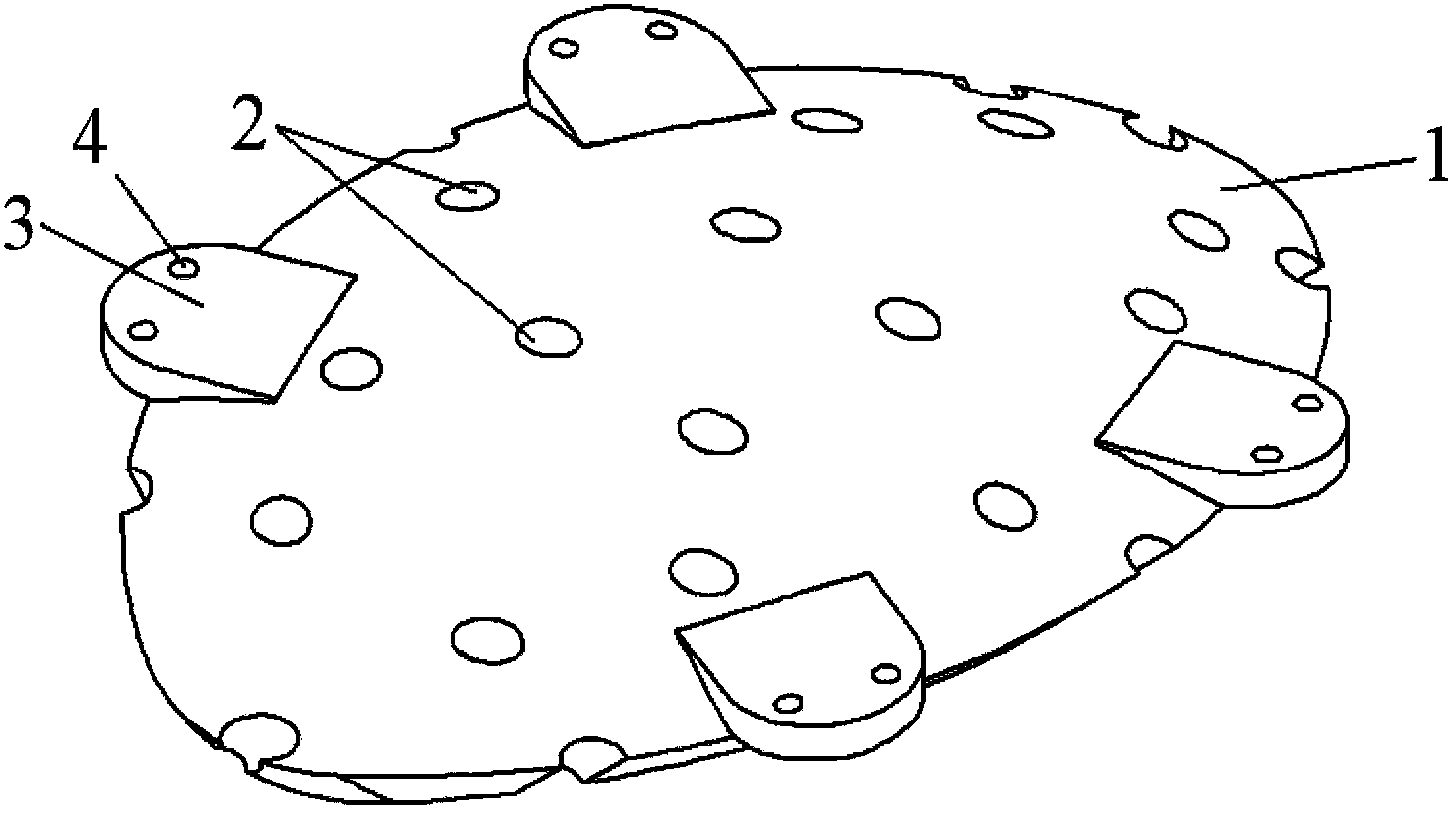

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] A method for preparing a skull flap to be repaired by 3D printing, the steps are as follows:

[0032] 1) Use a photographic 3D scanner to perform three-dimensional scanning of the original bone flap to be repaired at the skull defect, and obtain the three-dimensional data of the physical surface points of the original bone flap;

[0033] The original bone flap needs preliminary treatment before scanning. The original bone flap removed during the operation is soaked in 10% formalin solution for 4 hours, rinsed with clean water for 3 times, and the connective tissue attached to the surface of the skull flap is scraped off. The tissue is ready for the next scan. The cleaned original skull bone flap can also be placed in a drying oven, baked at 60°C for 6 hours, and kept at room temperature for a long time for future scanning.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com