Cutting anastomat and one-stage type triggering mechanism thereof

A firing mechanism and stapler technology, which is applied in the field of medical equipment, can solve the problems of reduced reliability of parts matching, high requirements for parts precision, and increased wound healing time, achieving high reliability, fast cutting, and reduced healing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be clearly and completely described below through specific embodiments in conjunction with the accompanying drawings.

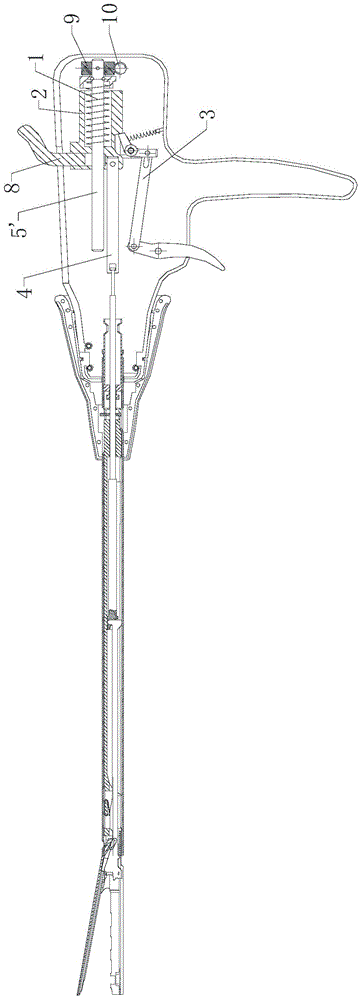

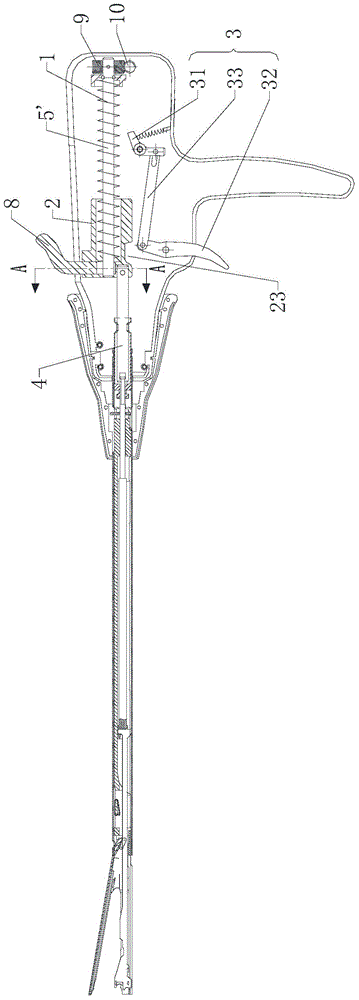

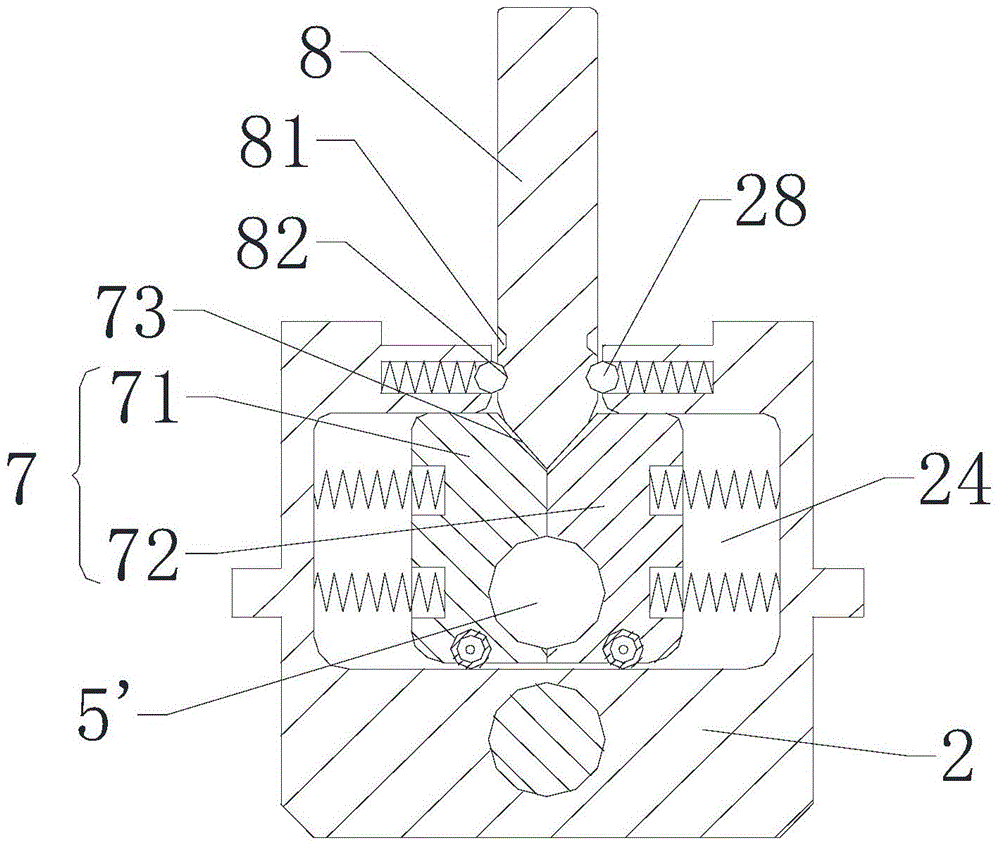

[0023] see Figure 1-4 As shown, the present invention provides a one-stage firing mechanism of a cutting stapler, including an elastic control assembly 1, a push assembly 2, a reset assembly, and an anchor release assembly 3. One end of the elastic control assembly 1 is fixed, and the other end is connected to the push Component 2, the push component 1 is connected to the reset component, and the reset component resets the push component 2, and the anchor release component 3 is used to hang on or release the push component 2, and the push component 2 moves toward the elastic control component 1 After the elastic control assembly 1 is compressed, the push assembly 2 is attached to the anchor release assembly 3 , and when the anchor release assembly 3 is released from the push assembly 2 , the elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com