Ultra-precise straightness measuring method based on single-measuring-head error separation

A technology of error separation and measurement method, which is applied in the field of measurement application, can solve problems such as parabolic cumulative error, thermal drift measurement influence, difficult and high-precision spacing, etc., to eliminate the influence of zeroing error, avoid the influence of thermal drift, and scan the range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

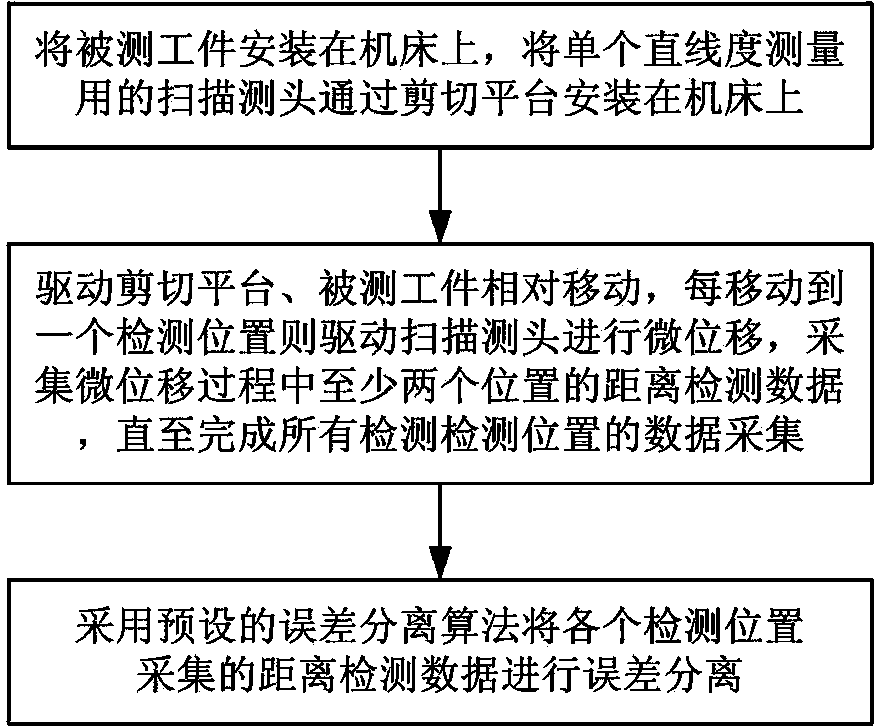

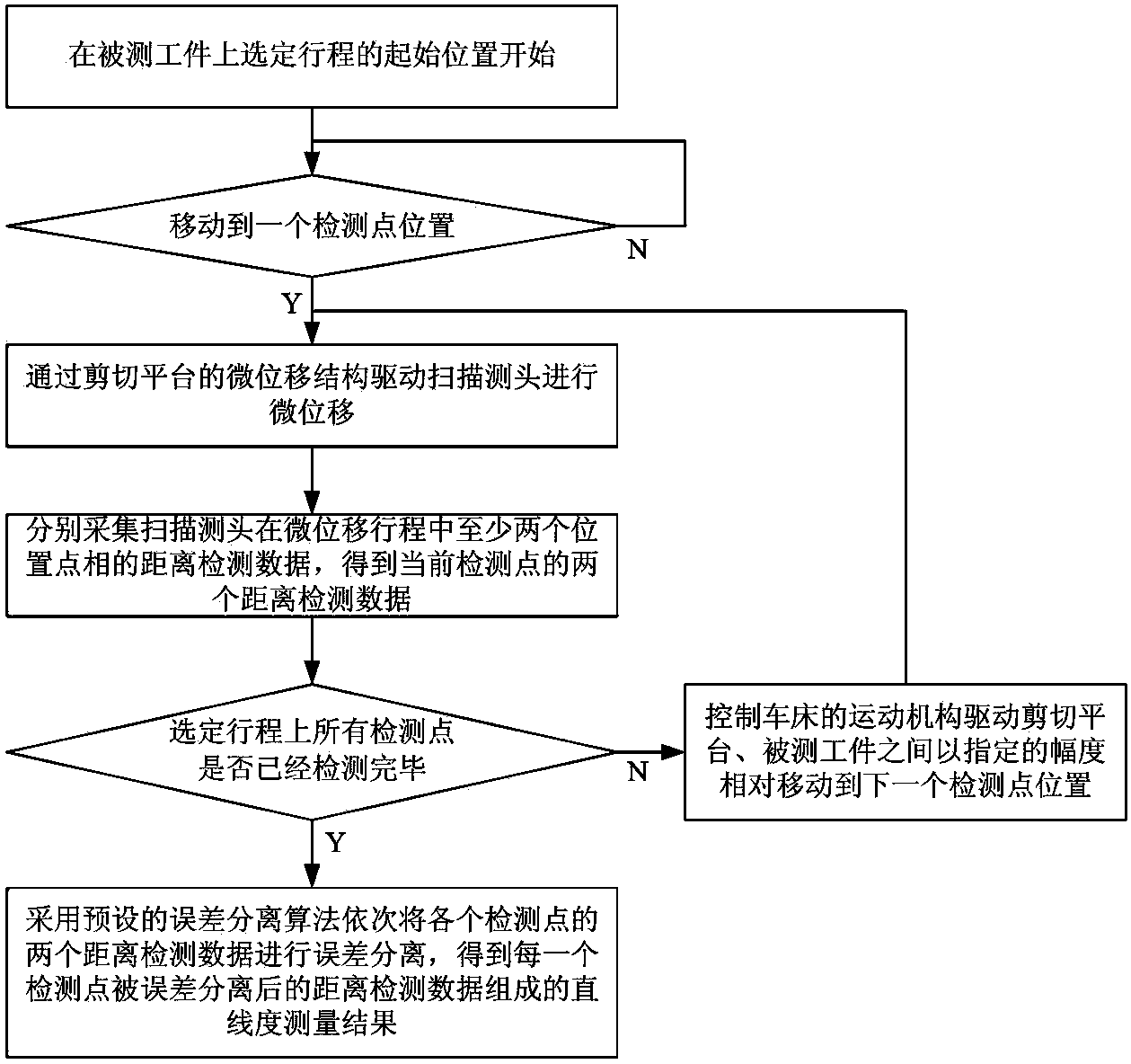

[0031] Such as figure 1 As shown, the implementation steps of the ultra-precise straightness measurement method based on single probe error separation in this embodiment are as follows:

[0032]1) Install the workpiece to be measured on the machine tool, install the single scanning probe for straightness measurement on the machine tool through the shearing platform with micro-displacement structure, and drive the workpiece or the shearing platform to realize shearing through the kinematic mechanism of the machine tool. The relative movement between the cutting platform and the measured workpiece. For the shearing platform and the workpiece to be tested, the large-scale linear scanning motion can be realized by the motion mechanism of the machine tool to drive the workpiece to be tested or the shearing platform to realize the relative movement between the shearing platform and the workpiece to be measured, which can be done by the workpiece. Linear motion or shearing platform ...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, the difference being that the structure of the machine tool used in step 1) is different.

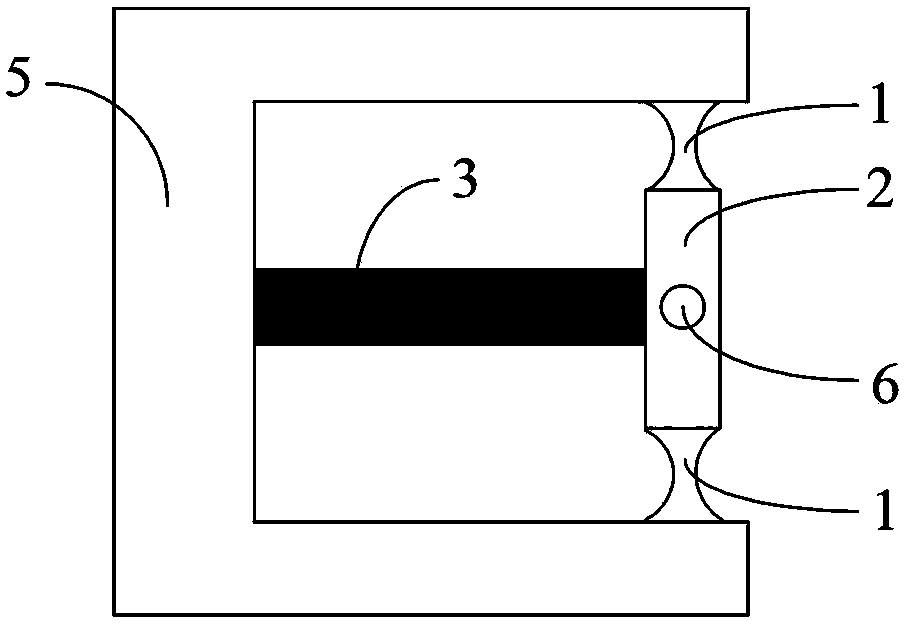

[0047] Such as Figure 6 As shown, the machine tool used in this embodiment is a diamond lathe with a C-axis function in a horizontal structure. The diamond lathe with a C-axis function has an XZ two-axis motion function, including a machine tool body 4, which is provided with an X Axis direction movement mechanism 41 and Z axis direction movement mechanism 43, X axis direction movement mechanism 41 is provided with a rotatable main shaft 8 (C axis), the workpiece 7 to be measured is mounted on the main shaft 8, and the scanning probe 6 has a micro-displacement The shearing platform 5 of the structure is installed on the moving mechanism 43 in the Z-axis direction. The shearing platform 5 is installed on the Z-axis direction movement mechanism 43 (where the diamond tool is installed), and moves horizontally with the Z-axis t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com