Ultra-static vacuum testing device and method

A testing device and vacuum technology, which is applied in the testing of measuring devices, pump devices, machines/structural components, etc., can solve problems such as inability to test, inaccurate test results of spacecraft ground vacuum, etc., to isolate vibration effects and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

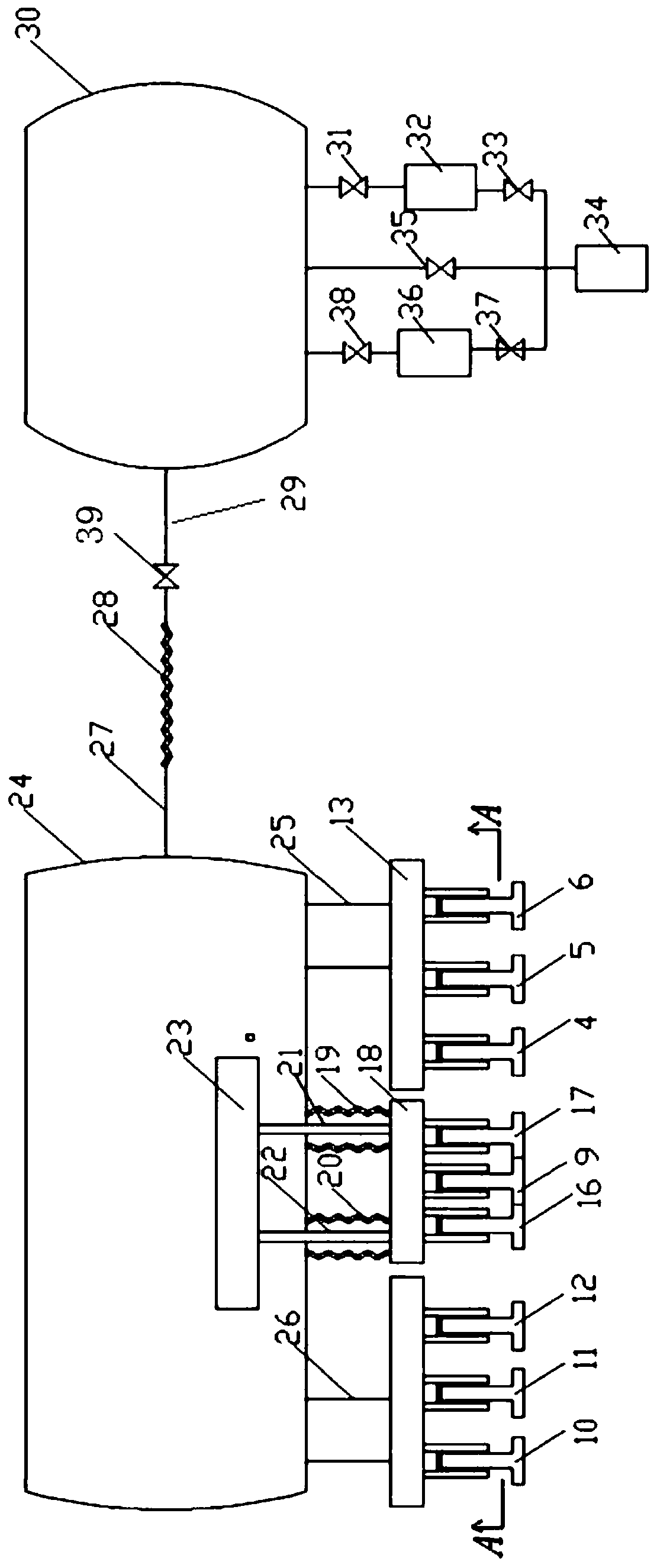

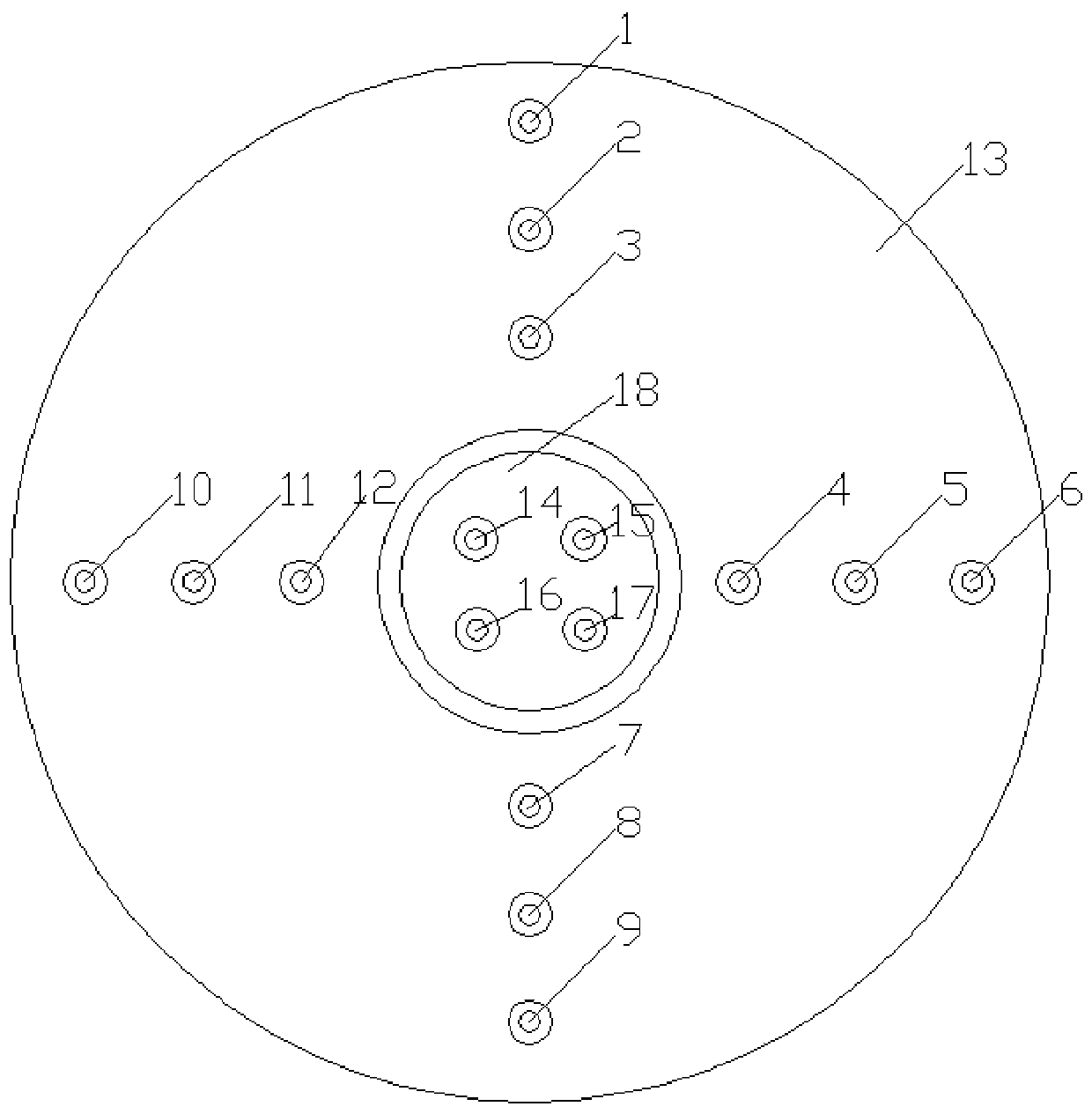

[0042] Such as figure 1 , 2 As shown, the ultra-quiet vacuum testing device provided in this embodiment includes a first air bearing platform, a second air bearing platform, a vacuum testing unit, an object loading platform unit and a vacuum pumping unit.

[0043] The first air bearing platform comprises the first supporting plate 13 of annular structure and the first air cylinder 1-12 that is arranged on the lower end of the first supporting plate 13; 1-12 are divided into four groups, which are evenly distributed on the lower end of the first support plate 13; the three first cylinders of each group are evenly arranged along the edge of the first support plate 13 toward the middle; cylinders 1-12 and cylinders 14- 17 Driven by compressed air, its pressure is not less than 0.5MPa.

[0044] The second air bearing platform comprises a second support plate 18 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com