Compact wireless embedded signal processor applied to cold-rolled strip shape meter

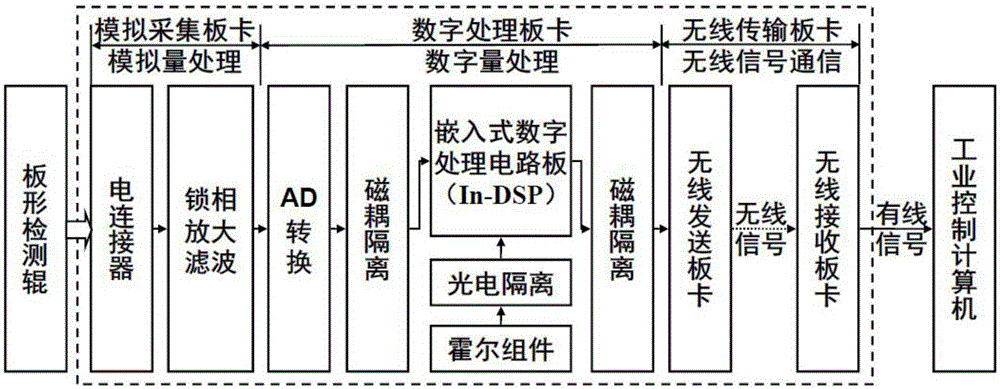

A signal processor, cold-rolled strip technology, applied in the direction of instruments, metal rolling, metal rolling, etc., can solve problems such as poor stability and reliability, difficult maintenance, signal distortion, etc., to improve transmission accuracy and service life, improve Stability and reliability, effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

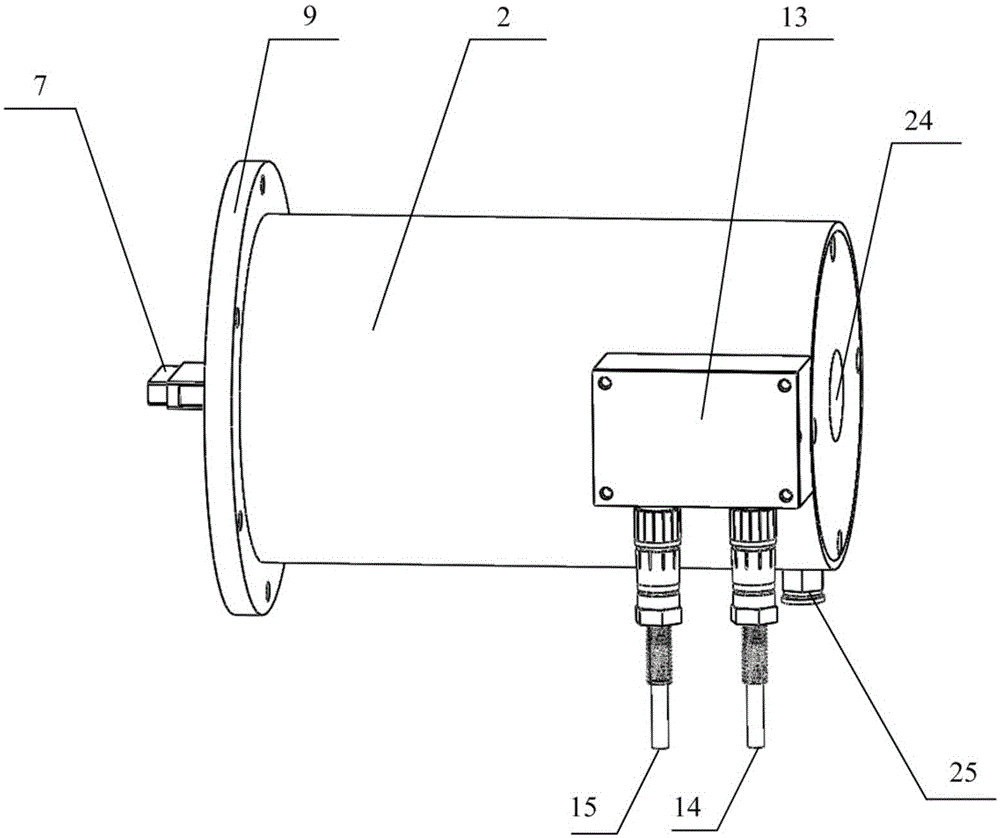

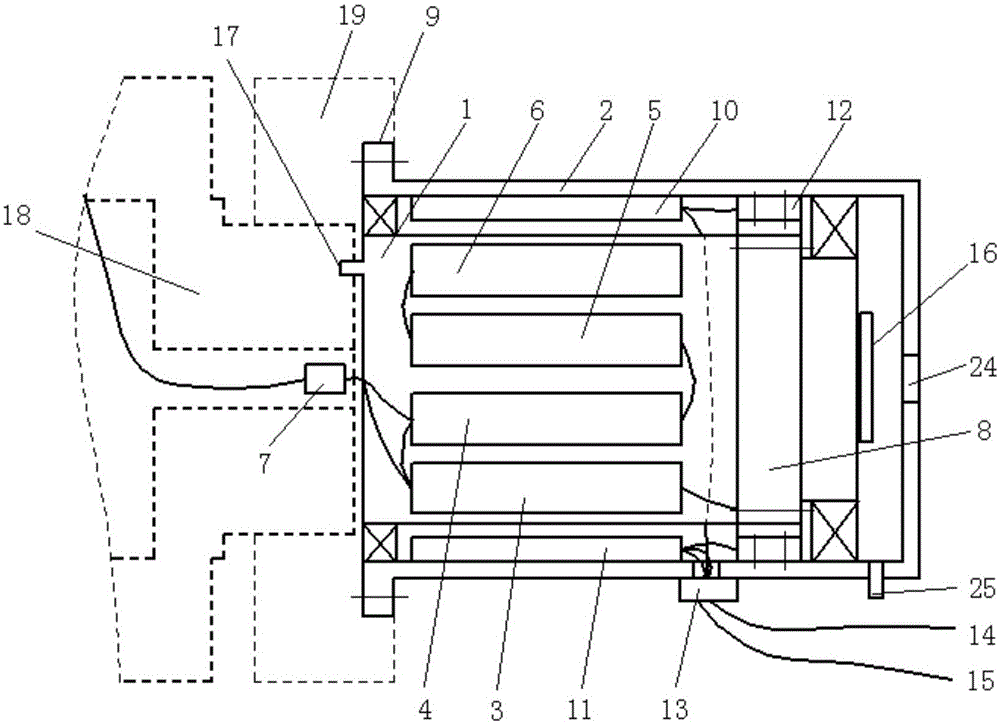

[0027] Such as figure 1 with figure 2 As shown, the present invention mainly includes a rotating head 1 and an outer cover 2. The rotating head is a cylindrical shaft structure, and an excitation power supply board (LC-AL) 3 and an analog acquisition board (MN-16AM) are installed inside the rotating head. 4. The digital processing board (SZ-DSP) 5 and the wireless sending board (WF-TX) 6 are installed with an outwardly protruding electrical connector 7 at the center of one end of the rotating head. The electrical connector adopts a circular or A square aviation connector, the inner magnetic ring 8 is sleeved and fixed on the outer wall of the other side of the rotating head;

[0028] The main body of the outer cover 2 is a cylindrical structure, and a connecting plate 9 with threaded holes is arranged on the edge of the opening end, and the rotating head is nested inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com