Small optical resolution photoacoustic microscope based on micro-electromechanical scanning galvanometer

A technology of micro-electromechanical scanning and photoacoustic microscopy, which is applied in the direction of material analysis, scientific instruments, and analytical materials through optical means, can solve the problems of inability to apply endoscopic imaging, image quality loss, and volume reduction, and achieve easy application and promotion, reduced size and weight, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

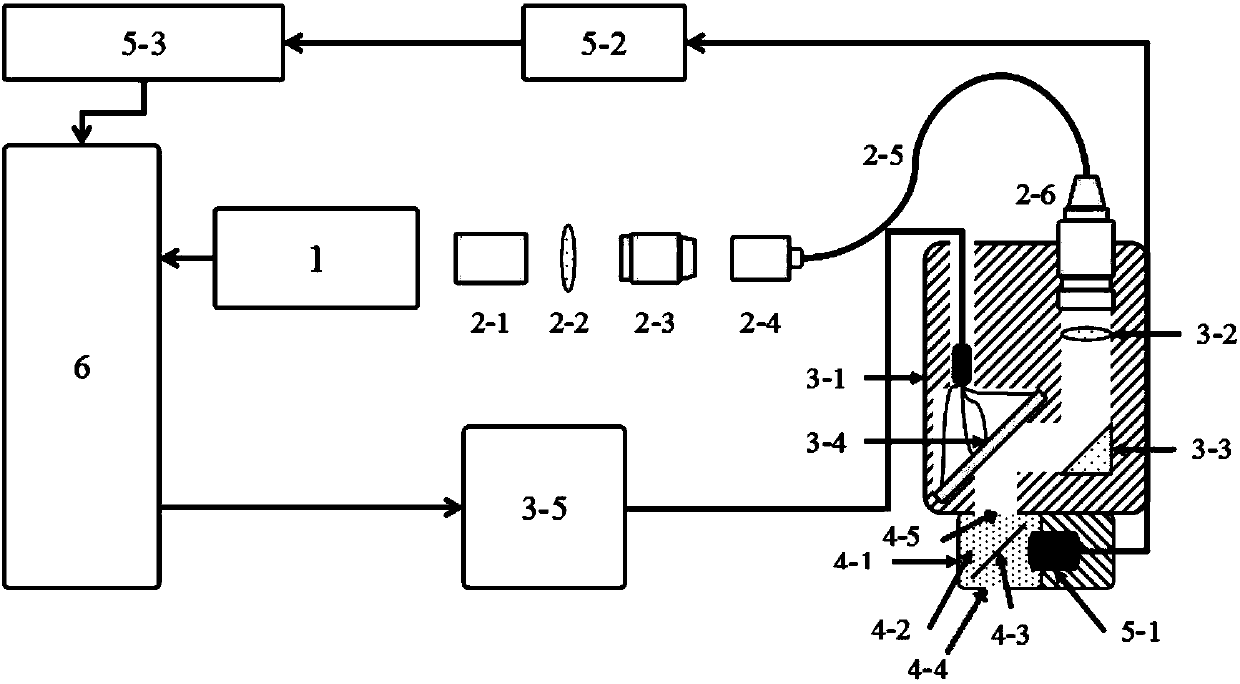

[0024] Such as figure 1 Shown is a schematic structural diagram of a small optical resolution photoacoustic microscope based on a MEMS scanning galvanometer provided in this embodiment, including a light source component, a single-mode fiber optical coupling component, a beam scanning component, a signal acquisition component and a computer, wherein, The light source assembly consists of a pulsed laser 1, which is electrically connected to a computer 6. The pulsed laser 1 is used to generate a pulsed laser with a pulse width between 1ns-10ns, a repetition frequency between 1Khz-100Khz, and a wavelength determined according to the imaging target. The spatial optical filter 2-1, the collimating lens 2-2, the objective lens 2-3, the single-mode fiber coupling adjustment frame 2-4 in the single-mode fiber coupling assembly are installed coaxially with the pulse laser 1 in turn, and pass through the single-mode fiber 2-5 and single-mode optical fiber collimating lens 2-6 are connec...

Embodiment 2

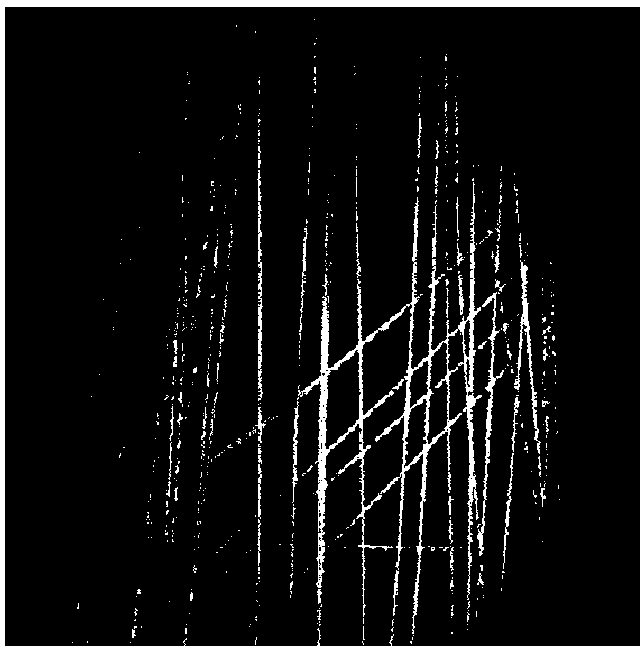

[0029] Example 2 Application of the method and device of the present invention to imaging carbon fiber filaments embedded in agar

[0030] Utilize the device of Example 1 to image the carbon fiber filaments buried inside the agar, wherein the wavelength of the pulsed laser output is 532nm, the pulse width is 2ns, the repetition frequency is 2000Hz, the scanning range is 2.5mm, and the scanning step is 5 μm, and a total of 500 samples are collected. group signals, obtained as figure 2 From the image shown, it can be seen from the image that the carbon fiber filaments in the agar can be clearly observed, indicating that the method and device of the present invention can obtain clear imaging of the target object in a relatively large imaging area.

Embodiment 3

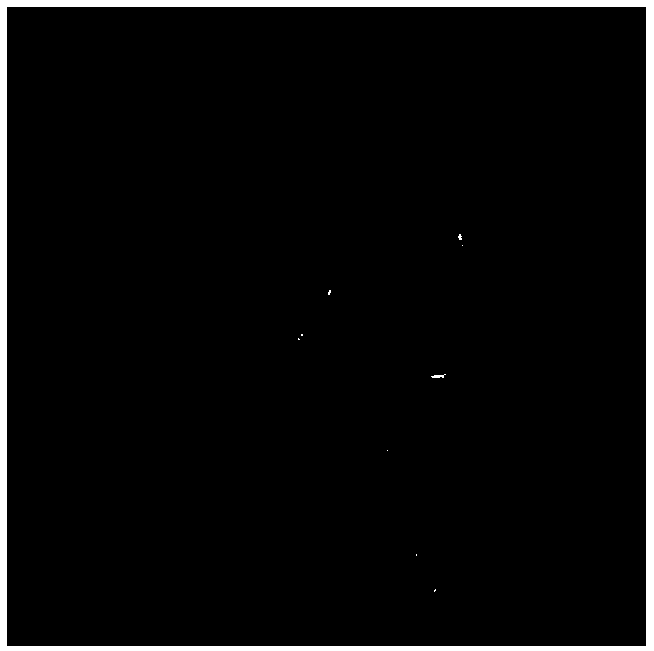

[0031] Example 3 Application of the method and device of the present invention to imaging of living mouse ear blood vessels

[0032] Utilize the device of embodiment 1 to carry out imaging to living mouse ear blood vessel, wherein the wavelength of pulse laser output is 532nm, pulse width 2ns, repetition frequency 2500Hz, two-dimensional scanning galvanometer system scans along the diameter of imaging area, and scanning range is 2.5 mm, with a scan step of 5 μm, a total of 500 sets of signals were collected, and the following image 3 As shown in the image, it can be seen from the image that the capillaries in the ear of the living mouse are clearly presented, indicating that the method and device of the present invention can image the target object with a high resolution.

[0033] The present invention utilizes the microelectromechanical scanning galvanometer in the photoacoustic microscope with optical resolution, which can greatly reduce the volume of the system. In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com