Method and system for damage repair of tube plate and caulk weld of steam generator of nuclear power station

A steam generator, damage repair technology, applied in welding equipment, applications, heat exchange equipment, etc., can solve the problem of inability to completely eliminate the impact of foreign body damage, and achieve the effect of eliminating the risk of hardened layer and stress corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

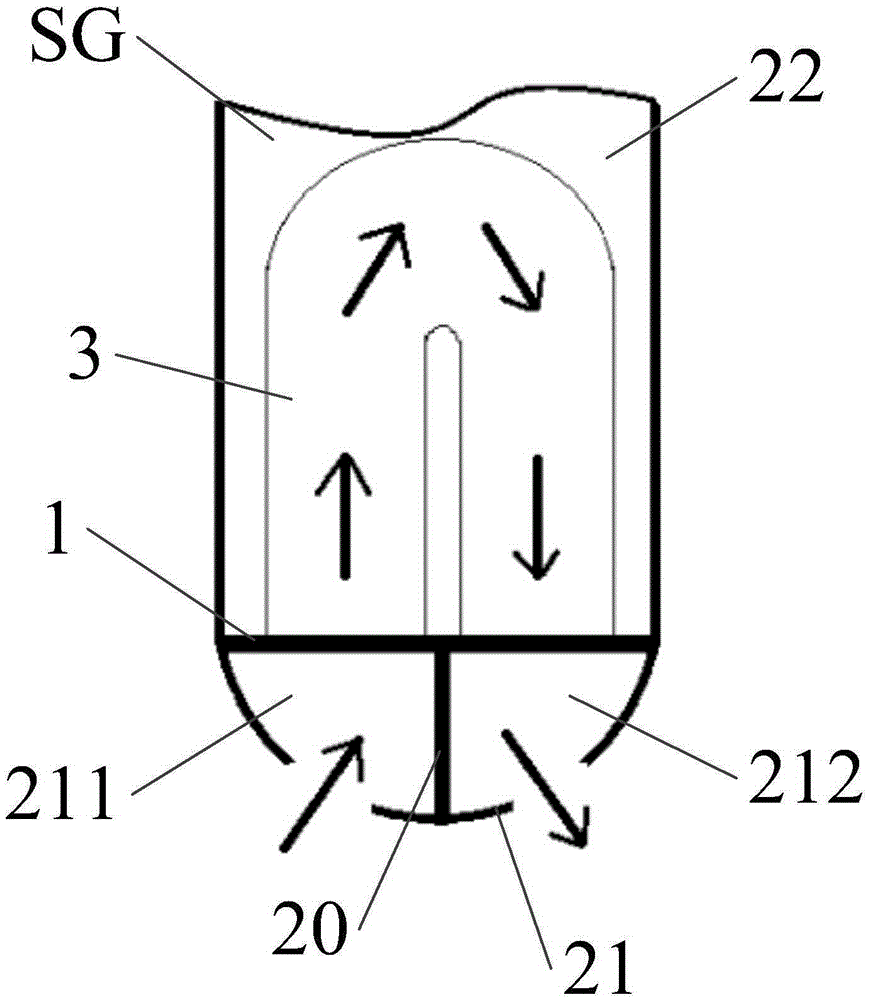

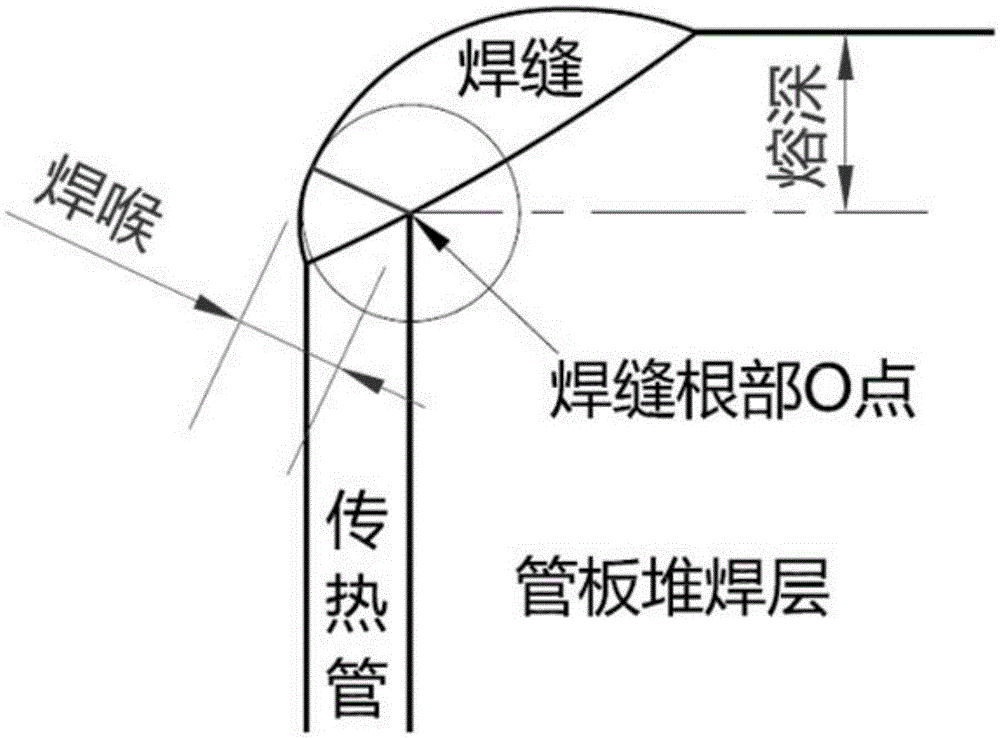

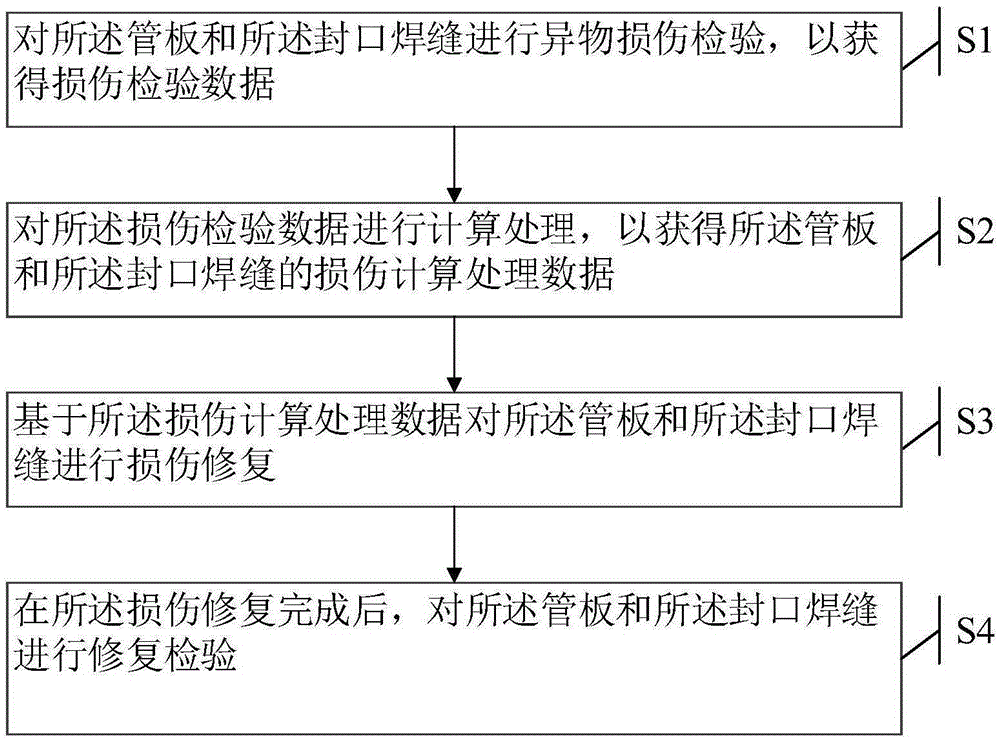

[0071] Please refer to image 3 , the embodiment of the present invention provides a method for repairing damage to the tube sheet and sealing weld of a steam generator in a nuclear power plant. Formed from the tube sheet and the sealing weld, the repair method includes the steps of:

[0072] S1. Carrying out foreign object damage inspection on the tube sheet and the sealing weld to obtain damage inspection data;

[0073] S2. Calculating and processing the damage inspection data to obtain damage calculation and processing data of the tube sheet and the sealing weld;

[0074] S3. Perform damage repair on the tube sheet and the sealing weld based on the damage calculation and processing data;

[0075] S4. After the damage repair is completed, perform a repair inspection on the tube sheet and the sealing weld to ensure that the repaired tube sheet and the sealing weld meet the equipment specification requirements.

[0076] It can be seen that the above step S1 is a damage insp...

Embodiment 2

[0094] Based on the same inventive concept, please refer to Figure 5A , the embodiment of the present invention also provides a nuclear power plant steam generator tube plate and sealing weld damage repair system, the sealing weld is fixedly connected to the tube plate and heat transfer tube of the steam generator, and the damage is caused by the impact of foreign matter The tube sheet and the sealing weld are formed, and the repair system includes:

[0095] A damage inspection module 51, configured to perform foreign object damage inspection on the tube sheet and the sealing weld to obtain damage inspection data;

[0096] A damage calculation and processing module 52, configured to perform calculation and processing on the damage inspection data, so as to obtain damage calculation and processing data of the tube sheet and the sealing weld;

[0097] A damage repair module 53, configured to perform damage repair on the tube sheet and the sealing weld based on the damage calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com