Welding device and method

A welding equipment, welding point technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of impracticality, dull work, waste of capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

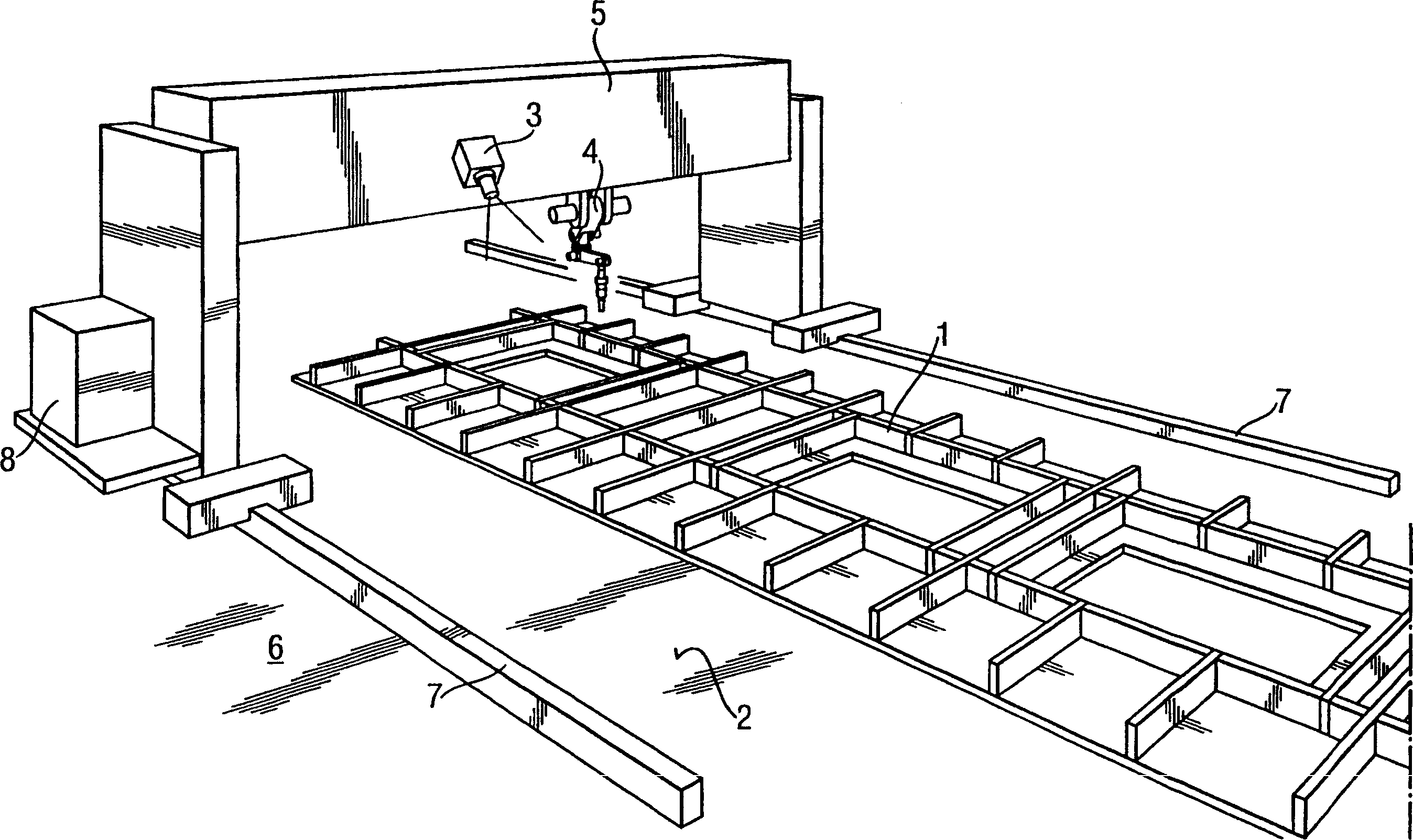

[0024] figure 1 A welding station or device is shown in which the individual components of a structural part 1 to be welded are supported on a support surface 2 . These components can be moved onto the support surface manually, by crane or by automatic material control. A camera 3 and a welding device 4 are fixed on a lateral support structure 5 which straddles the support surface 2 and which can be moved along the length of the support surface 2 via side rails 7 mounted on the ground 6 , the side rails are located on both sides of the supporting surface 2 respectively. A handling device 8 for handling the support structure 5 and / or the welding device 4 and / or the camera 3 is located close to the support structure 5 .

[0025] The term "camera" is intended to include any imaging device capable of providing an image of the structure to be welded, and may include conventional photographic devices such as a video camera or just a camera, imaging devices with infrared or ultravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com