Electric arc additive and electric auxiliary ultrasonic impact reinforcing composite manufacturing method and device

A technology of ultrasonic impact and manufacturing method, applied in the direction of manufacturing tools, additive processing, arc welding equipment, etc., can solve the problems of limited improvement, large deformation resistance, impact deformation and limited depth of residual compressive stress layer, etc. The effect of reducing heat generation and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the substrate is Inconel 718 superalloy rolled plate with a size of 300mm×50mm×4mm. The welding wire is Inconel 718 superalloy welding wire with a diameter of 1mm, and plasma welding is adopted. The specific implementation steps are as follows:

[0034] 1) Clean the surface of the superalloy substrate 5 with an alkaline solution to remove oil stains, polish the surface of the substrate 5 to remove the oxide film, and clean the surface with an acetone reagent.

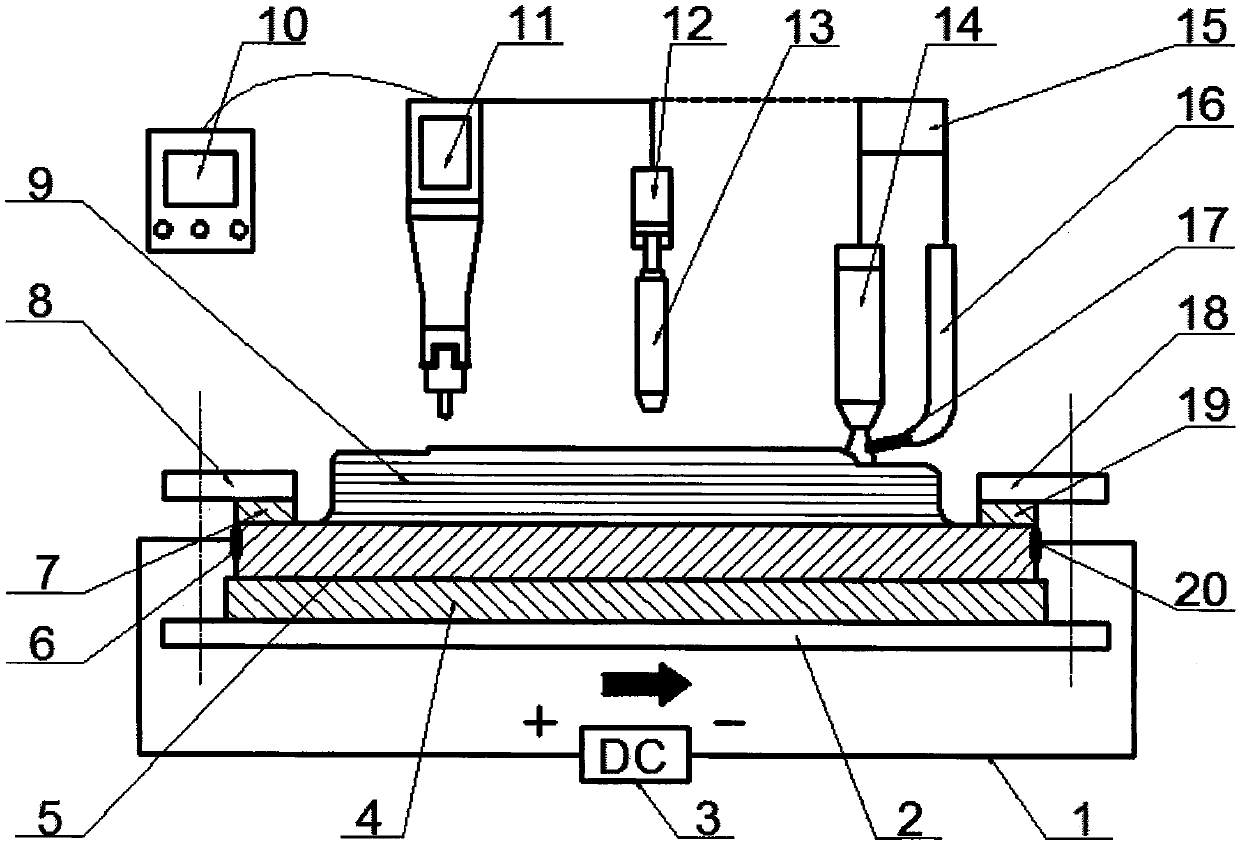

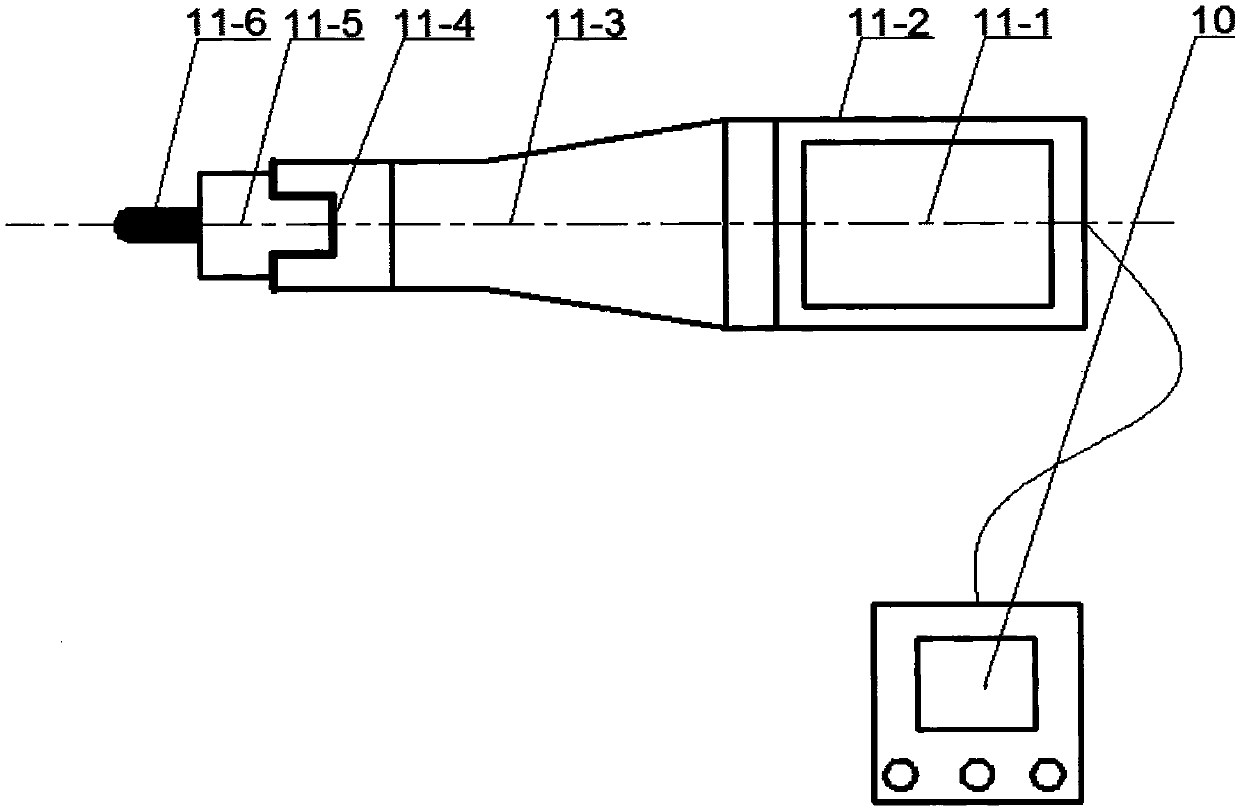

[0035] 2) Insert an insulating gasket 4 with a size larger than the substrate 5 between the substrate 5 and the worktable 2; insert insulating gaskets 7 and 19 between the substrate 5 and the left and right clamps 8 and 18, and pass the left and right clamps 8 and 18. 18 is fixed; the insulating gasket 11-4 is inserted at the position where the horn 11-3 is in contact with the clamping handle 11-5.

[0036] 3) The two electrodes 6 and 20 are respectively connected to the left and right sides o...

Embodiment 2

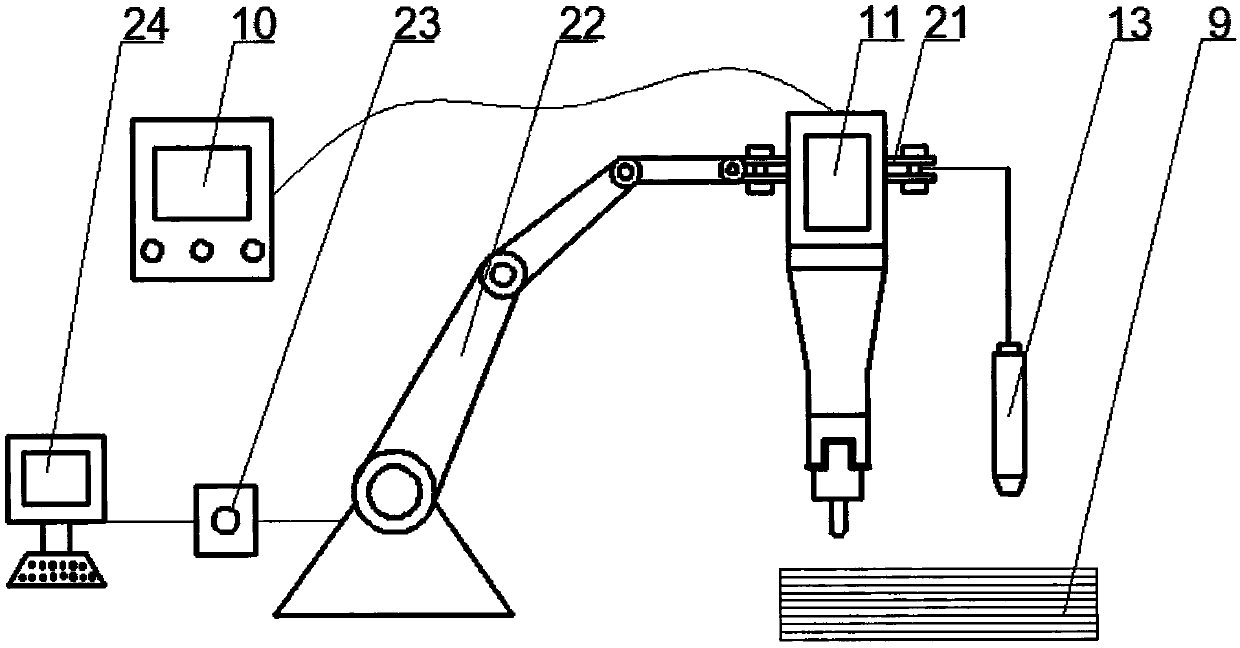

[0043] The ultrasonic impact device 11 of the present invention can also be assembled and used through the cooperative control of the robot 22, such as image 3 , because the robot 22 can realize complex spatial curved surface activities, has higher flexibility and motion precision, and can form parts with higher complexity. A clamping device 21 is added at the end of the multi-joint robot 22 for clamping the ultrasonic impact device 11 . According to the characteristics and dimensions of the formed parts, the computer 24 slices the three-dimensional part features to obtain the best path, generates the path trajectory, and transmits the instructions of the computer 24 to the controller 23, and then controls the multi-joint robot 22 to change the posture, and enters the Ultrasonic impact strengthens the initial position. After the arc additive is completed, the DC pulse power supply 3 is used to heat the specified forming temperature, the ultrasonic generator 10 is turned on, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com