Method for dividing working area of robot

A working area and robot technology, applied in the field of robotics, can solve the problems of robot moving speed limitation, lower robot work efficiency, complicated setting operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to achieve the above-mentioned purpose, the technical means and effects thereof adopted by the present invention are now given as preferred embodiments, and are described as follows in conjunction with the accompanying drawings.

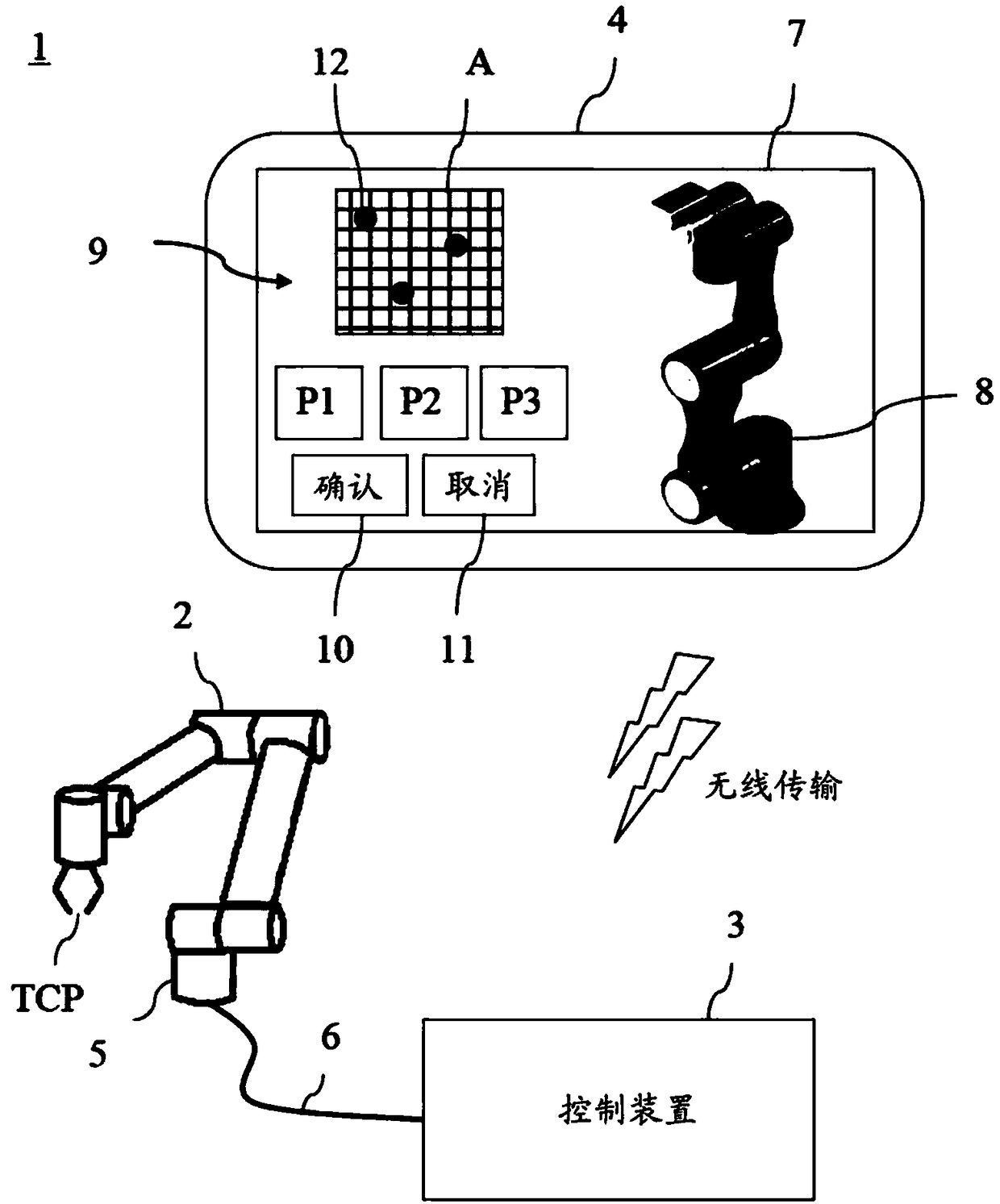

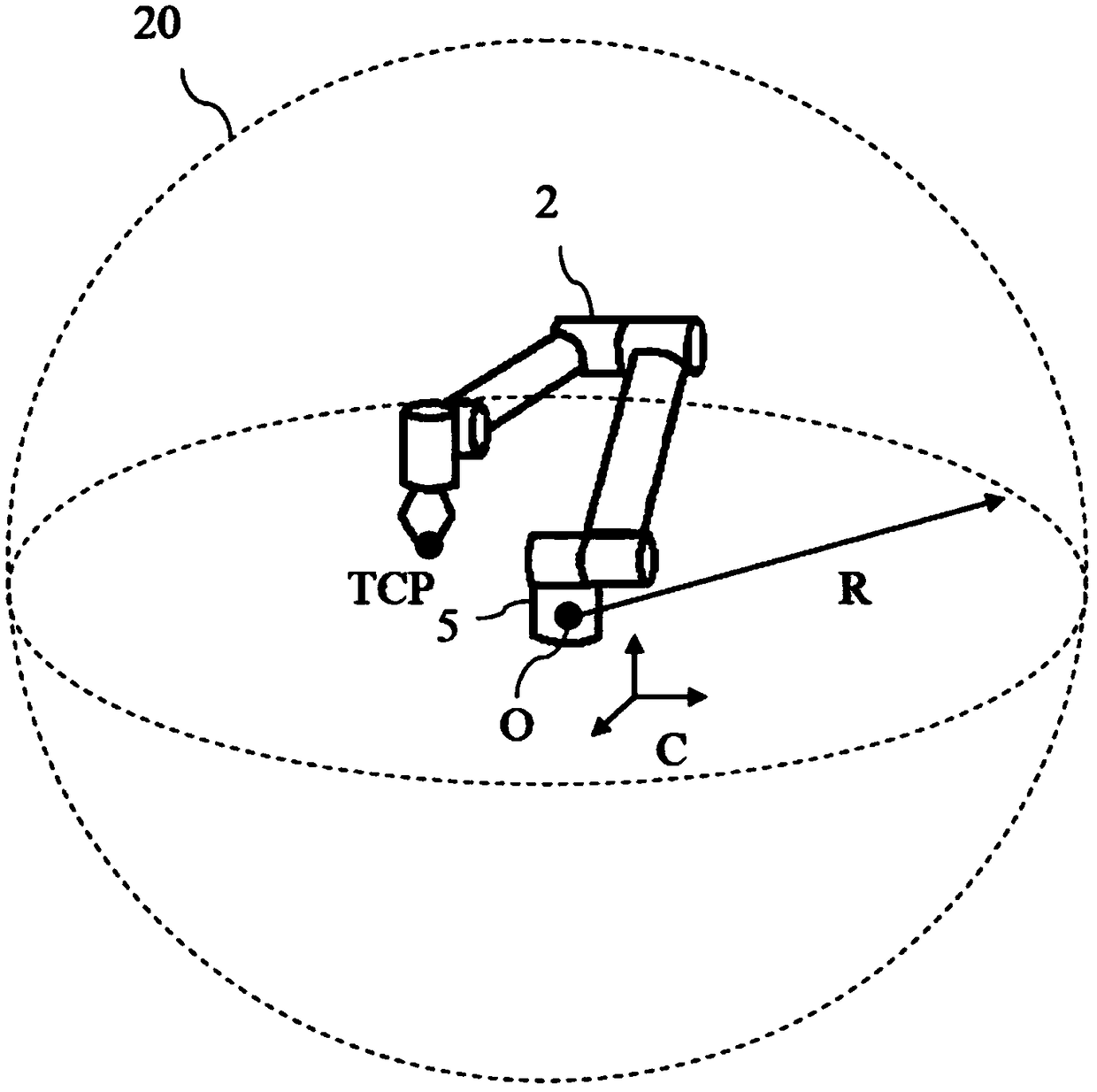

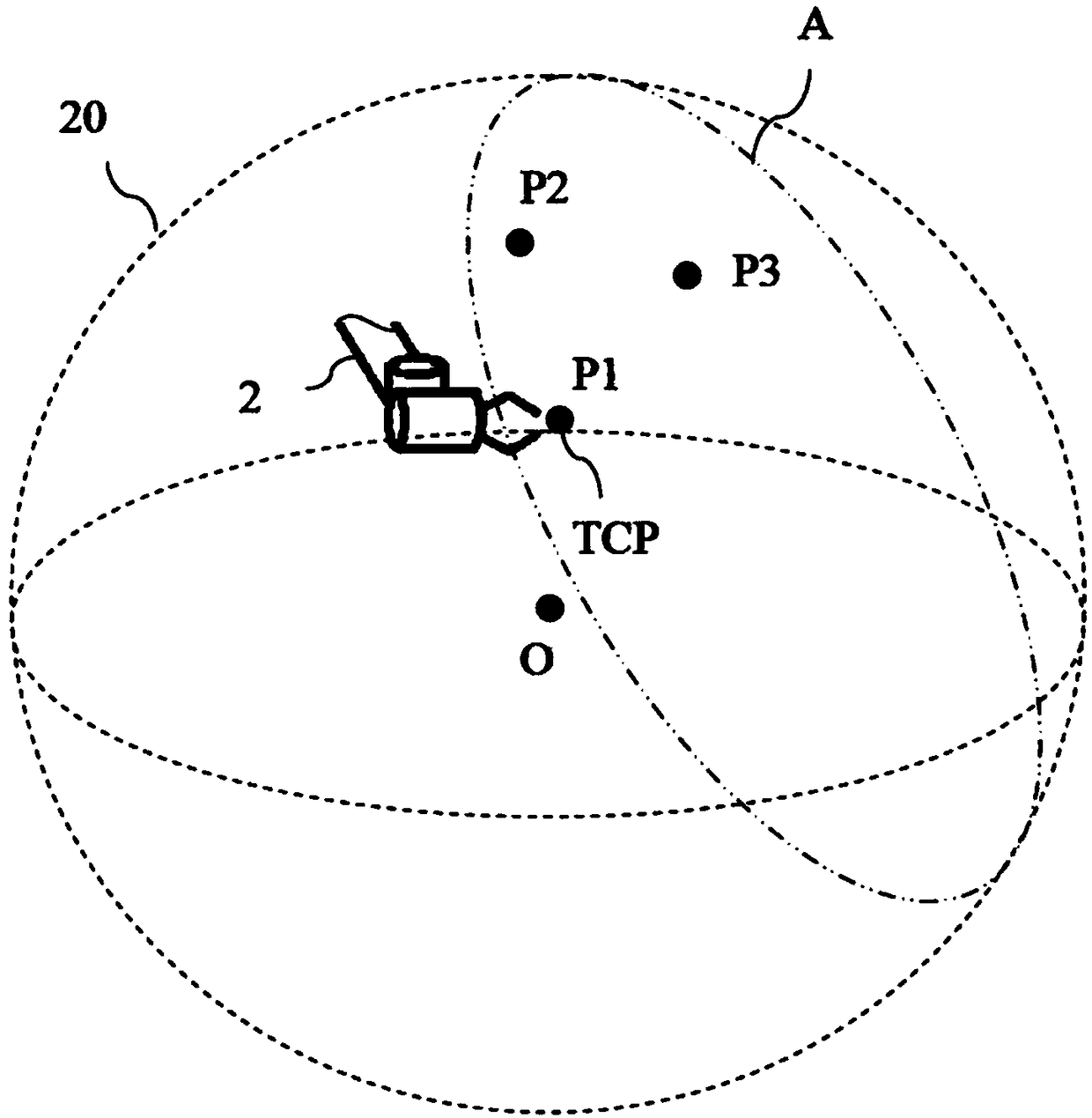

[0041] Please also refer to figure 1 , figure 2 and image 3 , figure 1 It is a schematic diagram of the robot control system of the present invention, figure 2 It is a schematic diagram of the working area of the robot of the present invention, image 3 Schematic diagram of the separation interface constructed for the present invention. figure 1 Among them, the robot control system 1 of the present invention includes a robot 2, a control device 3, a man-machine interface 4, and the like. The robot 2 is a multi-axis type, the fixed end is the base 5 , and the other end is the movable Tool Center Point (TCP). The control device 3 is connected to the robot 2 via a cable 6 for controlling the robot 2 to move the tool end TCP. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com