Multi-station robot automatic board contracting and releasing machine provided with robot

An automatic retractable and robotic technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency and poor precise positioning, and achieve the effect of flexible action and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] For the four-station automatic retractable board machine, the six-axis robot is used for grasping and releasing boards. The adsorption device includes a suction cup and a vacuum system for adsorbing circuit boards, and the adsorption device can adjust the suction force of the suction cup and the number of activated suction cups to meet the adsorption needs of circuit boards of different specifications. The circuit board carrier placement platform includes roller sets, carrier locking mechanism, etc. to place and lock the carrier frame, and also has a trolley locking mechanism, which can push the circuit board carrier to the circuit board carrier. The tool placement platform is locked and fixed. The conveying platform is used to transport circuit boards, and the circuit board carrier trolley is used to transport circuit board carriers. The bottom frame is a welded frame to support other components, the outer frame is made of profiles, and acrylic is used as a door panel...

Embodiment 2

[0053] For the three-station automatic retractable board machine, the three sets of circuit board carrier trolleys are docked with the first, second and third circuit board carrier placement platforms respectively, and then the circuit board carrier carts are locked , and push one of the circuit board carrier racks into the first circuit board carrier placement platform, the robot grabs the circuit board and places it on the delivery platform (it can be placed in the center, left or right as required), and then transports The platform starts to output the circuit boards. After the circuit boards are emptied, they exit the circuit board carrier racks, replace them with the circuit board carrier racks with circuit boards and repeat this cycle. At the same time, the robot grabs the spacer and places them on the other two groups of circuit boards. On the carrier rack, when the circuit board carrier rack is full of spacers, exit the circuit board carrier rack, replace it with the ci...

Embodiment 3

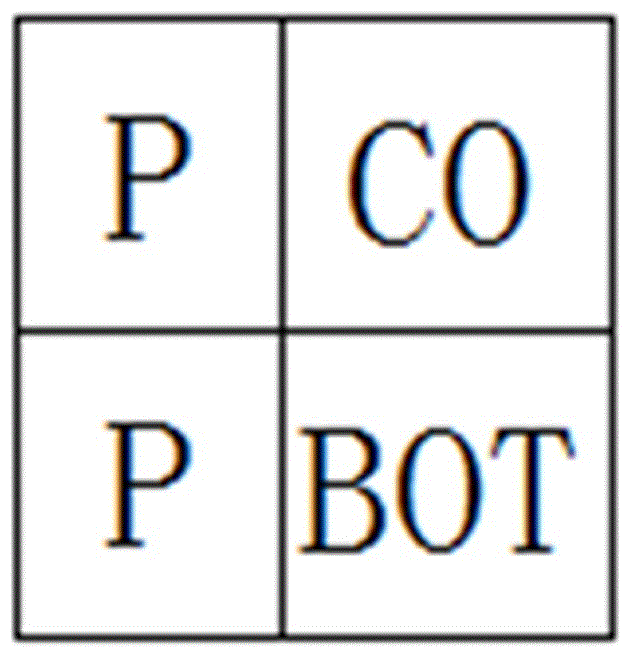

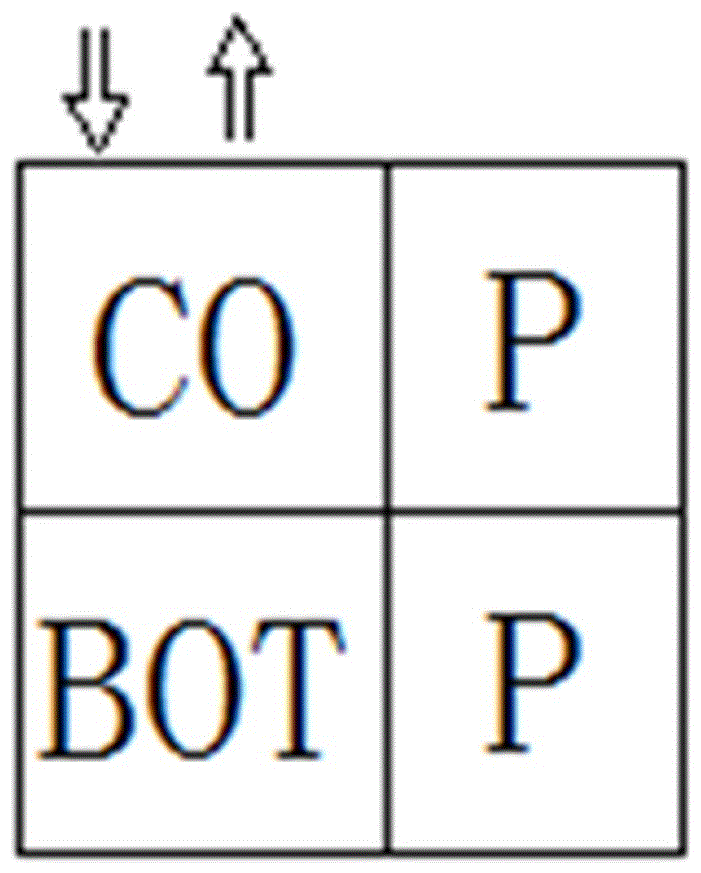

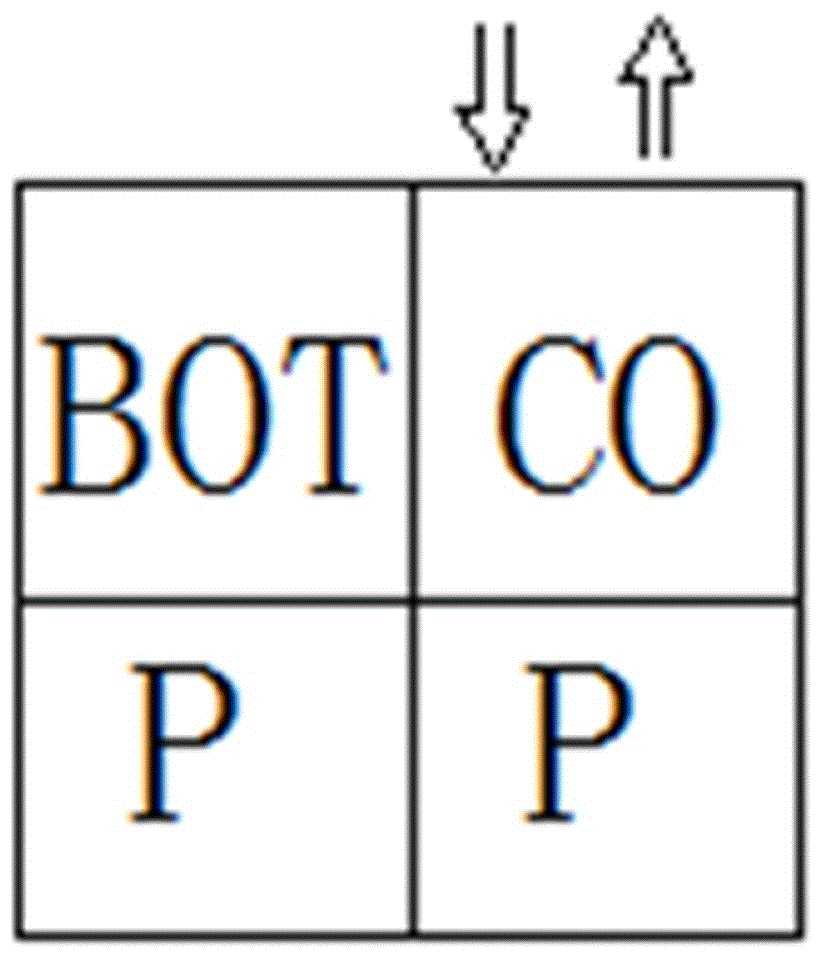

[0057] The entire bottom frame is divided into a nine-square grid. The middle grid is equipped with a six-axis robot. One end of the six-axis robot is provided with a delivery platform. The delivery platform is provided with an extension platform that extends to the outside of the bottom frame. The six-axis robot and The two sides of the conveying platform are divided into 6 circuit board carrier placement platforms, and the 6 circuit board carrier placement platforms are arranged correspondingly in groups of two to facilitate the corresponding operation when the circuit board needs to increase the film, so that The operation is simpler and faster. The six-axis robot is used for grasping and placing boards. The adsorption device includes a suction cup and a vacuum system for adsorbing circuit boards, and the structure of the adsorption device can be adjusted to meet the adsorption needs of circuit boards of different specifications. The circuit board carrier placement platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com