Substrate processing apparatus and substrate processing method

a substrate processing and processing apparatus technology, applied in the direction of cleaning process and apparatus, cleaning using liquids, semiconductor/solid-state device testing/measurement, etc., can solve problems such as poor drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

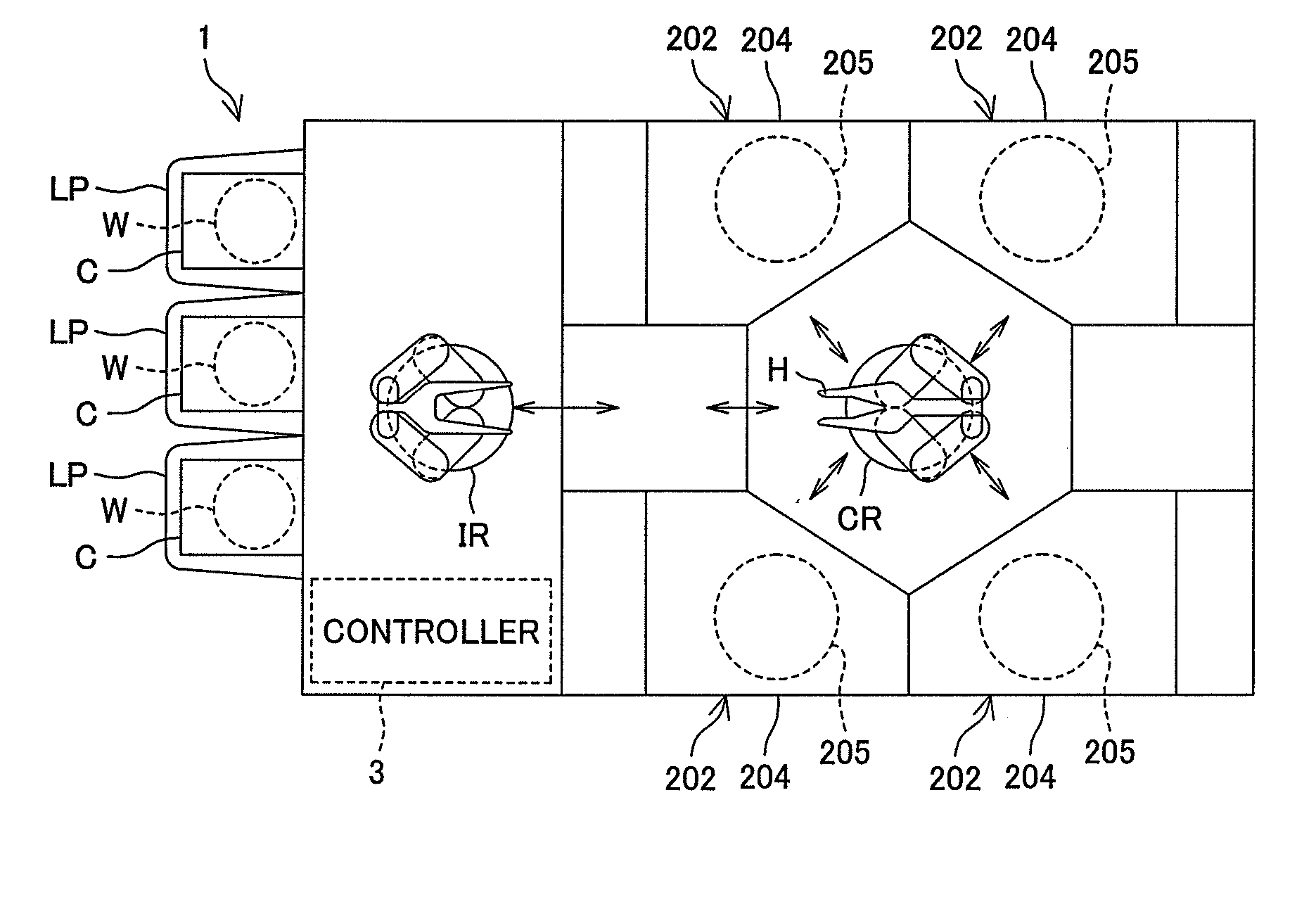

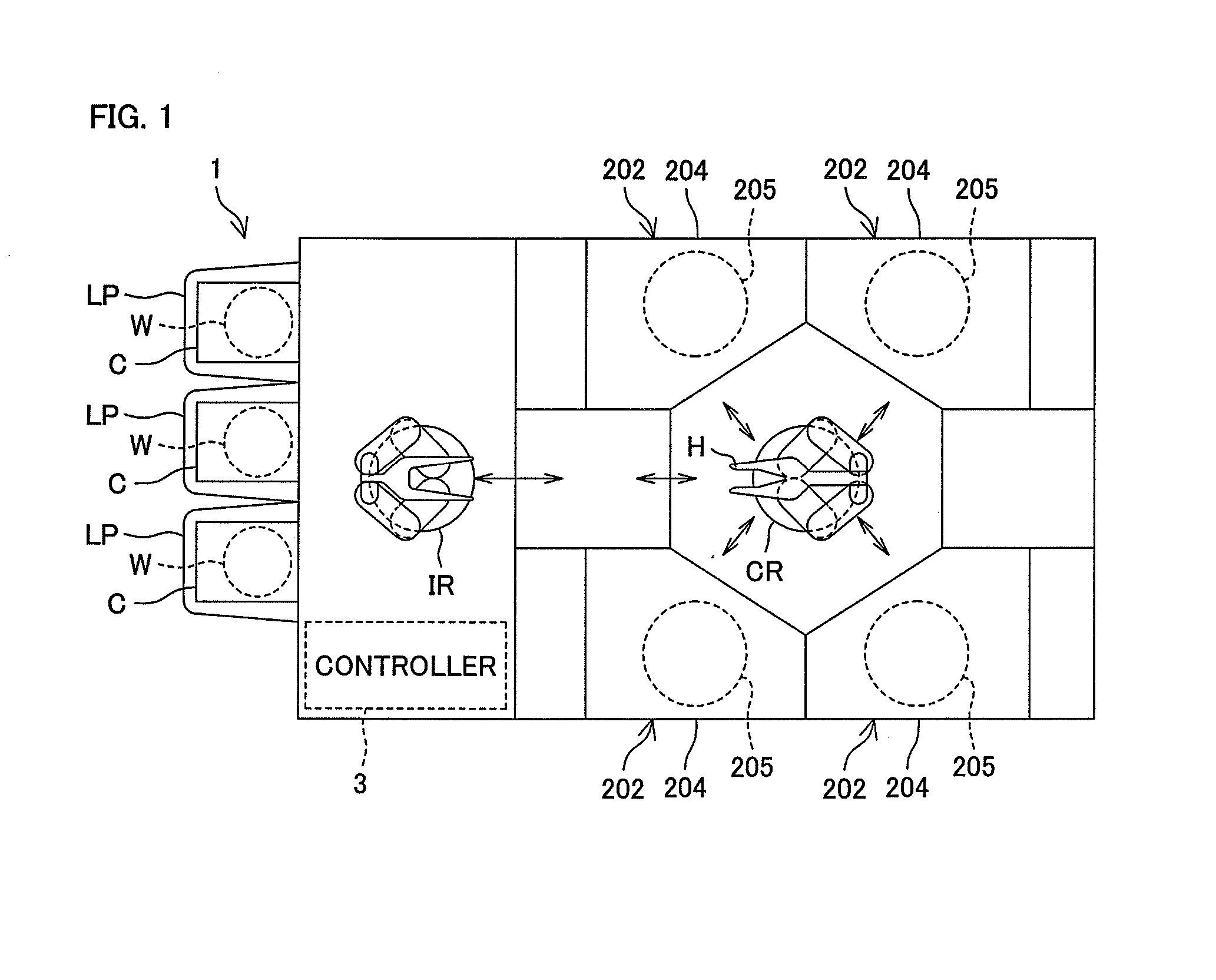

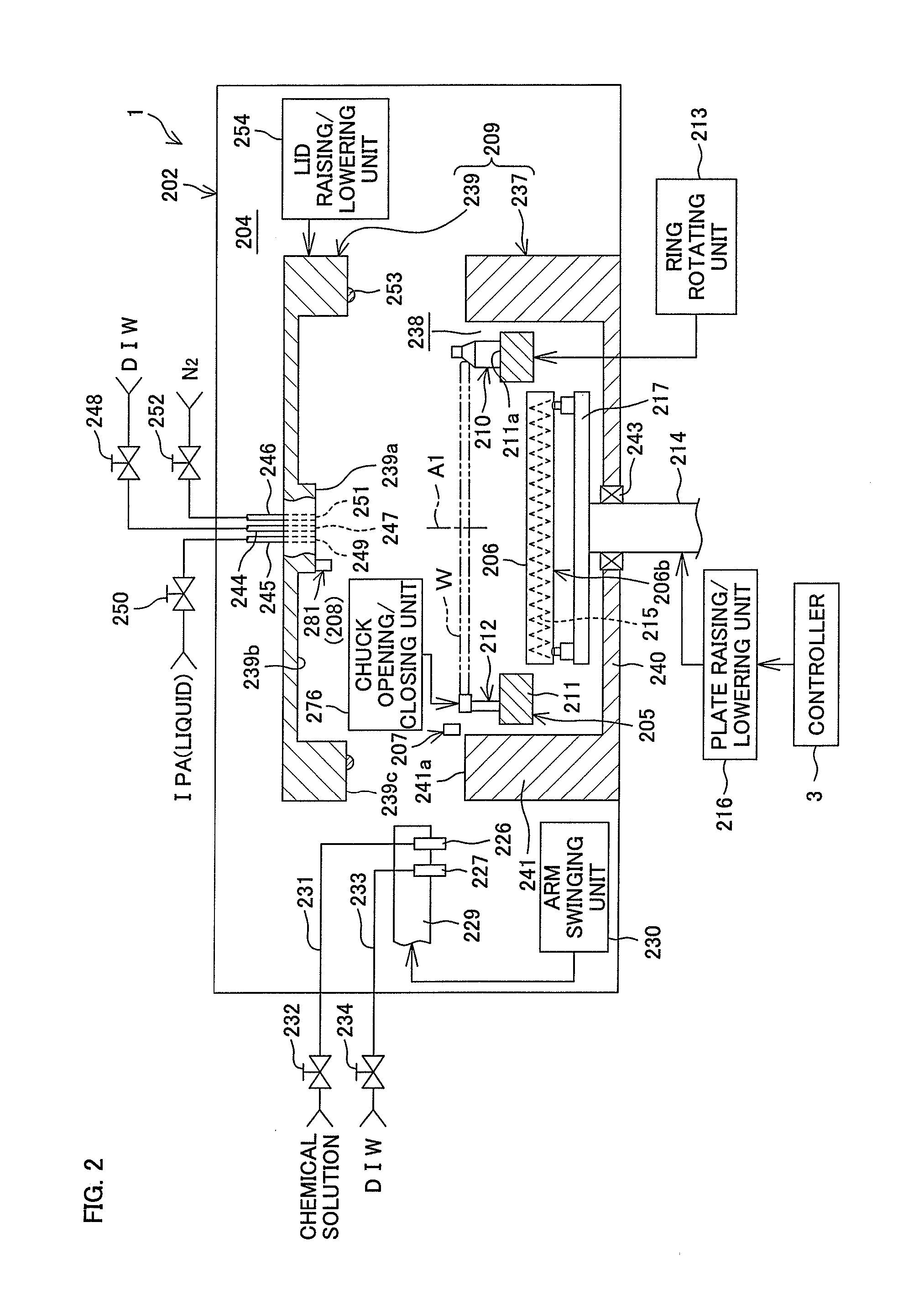

[0106]FIG. 1 is a schematic plan view of a substrate processing apparatus 1 according to a first preferred embodiment of the present invention. FIG. 2 is a schematic vertical cross-sectional view of a processing unit 202 included in the substrate processing apparatus 1 shown in FIG. 1.

[0107]The substrate processing apparatus 1 is a single substrate processing type in which disk-shaped substrates W such as silicon wafers are processed one by one. As shown in FIG. 1, the substrate processing apparatus 1 includes multiple processing units 202 arranged to process the substrates W with processing liquid, load ports LP on which carriers C are placed to house the respective multiple substrates W to be processed in the processing units 202 therein, delivery robot IR and delivery robot CR arranged to deliver the substrates W between the load ports LP and the processing units 202, and a controller 3 arranged to control the substrate processing apparatus 1.

[0108]The processing units 202 are si...

second preferred embodiment

[0253]Next will be described a second preferred embodiment of the present invention. In FIG. 32 and the following figures, components equivalent to those shown in FIGS. 1 to 31 are designated by the same reference symbols as in, for example, FIG. 1 and description thereof shall be omitted.

[0254]As shown in FIG. 32, the processing unit 2 includes a first substrate holding unit 15 arranged to rotate a substrates W about a vertical axis of rotation A1 passing through the center of the substrate W while keeping the substrate W in a horizontal attitude and a second substrate holding unit 29 arranged to heat the substrate W while keeping the substrate W in a horizontal attitude. The first substrate holding unit 15 and the second substrate holding unit 29 are examples of the substrate holding unit.

[0255]As shown in FIG. 32, the processing unit 2 further includes an openable / closable inner chamber 7 to house the first substrate holding unit 15 and the second substrate holding unit 29 therei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com