Five-charge three-discharge storage battery container formation method

A technology of internalization and storage battery, which is applied in the field of internalization of storage batteries by the method adopted, can solve the problems of difficult control of temperature rise in the formation process, waste of energy loss, affecting battery life, etc., and achieve reliable quality, reduce productivity, save man-hours and energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with examples, which are only used to explain the present invention, and do not limit the protection scope of the present invention.

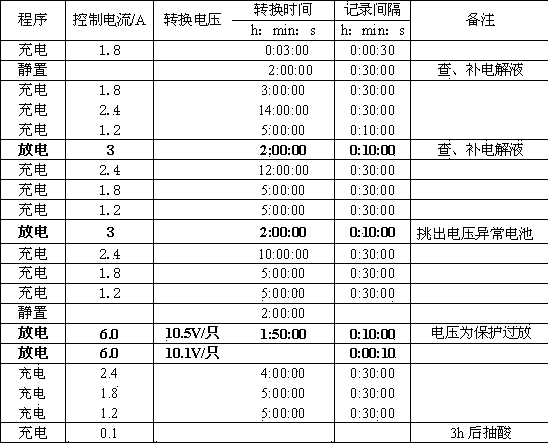

[0017] As shown in the embodiment, the present invention is a five-charge-three-discharge storage battery internal formation method, and the storage battery adopts the five-charge-three-discharge steps for internal formation, specifically including the following steps:

[0018] (1) The first charge: first charge with 1.8A current for three minutes, then stand still for two hours, check and replenish the electrolyte to keep the density of the electrolyte at 1.26g / cm3; when charging, every 30 seconds Just make a record of the battery and check the quality of the battery at all times;

[0019] (2) The second charge: charge the above battery for three hours with 1.8A current, record the formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com