Substrate liquid processing apparatus and substrate liquid processing method

A liquid treatment and treatment liquid technology, applied in the field of computer-readable recording media, can solve the problems of substrate etching treatment, concentration increase, silicon concentration increase, etc., and achieve a good effect of reducing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, specific configurations of a substrate liquid processing apparatus, a substrate liquid processing method, and a substrate liquid processing program according to the present invention will be described with reference to the drawings.

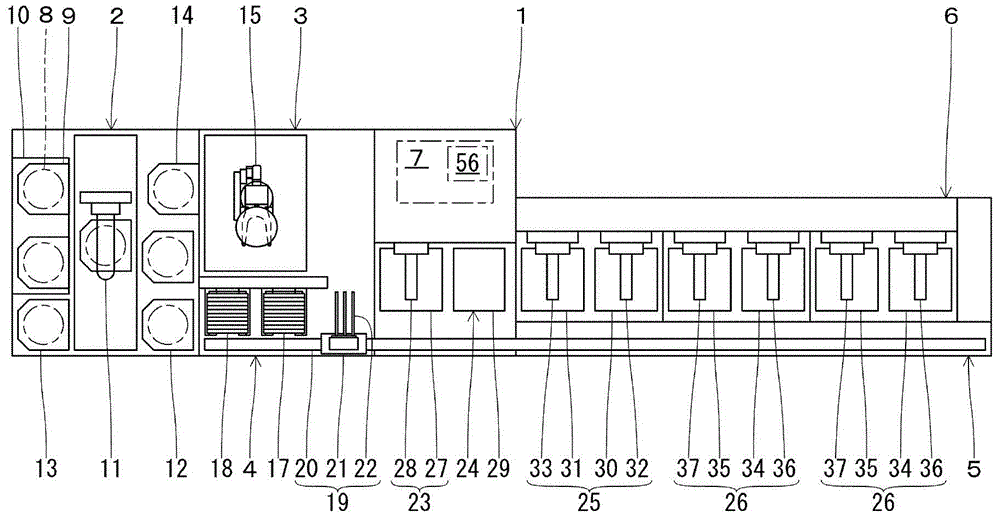

[0033] Such as figure 1 As shown, the substrate liquid processing apparatus 1 has a carrier loading and unloading unit 2 , a substrate group forming unit 3 , a substrate group placing unit 4 , a substrate group conveying unit 5 , a substrate group processing unit 6 , and a control unit 7 .

[0034] The carrier loading / unloading unit 2 loads and unloads the carrier 9 that accommodates a plurality of (for example, 25) substrates 8 arranged vertically in a horizontal posture.

[0035] The carrier loading and unloading section 2 is provided with a carrier table 10 on which a plurality of carriers 9 are placed, a carrier transport mechanism 11 which transports the carriers 9 , carrier holders 12 and 13 which temporarily store the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com