Auxiliary system for diesel engine

A diesel engine and auxiliary system technology, applied in engine components, combustion engines, engine cooling, etc., can solve the problems of relatively high casting technology level requirements, low system integration, inconvenient maintenance and installation, etc., to reduce waste. The effect of productivity, simplified assembly process, convenient maintenance and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

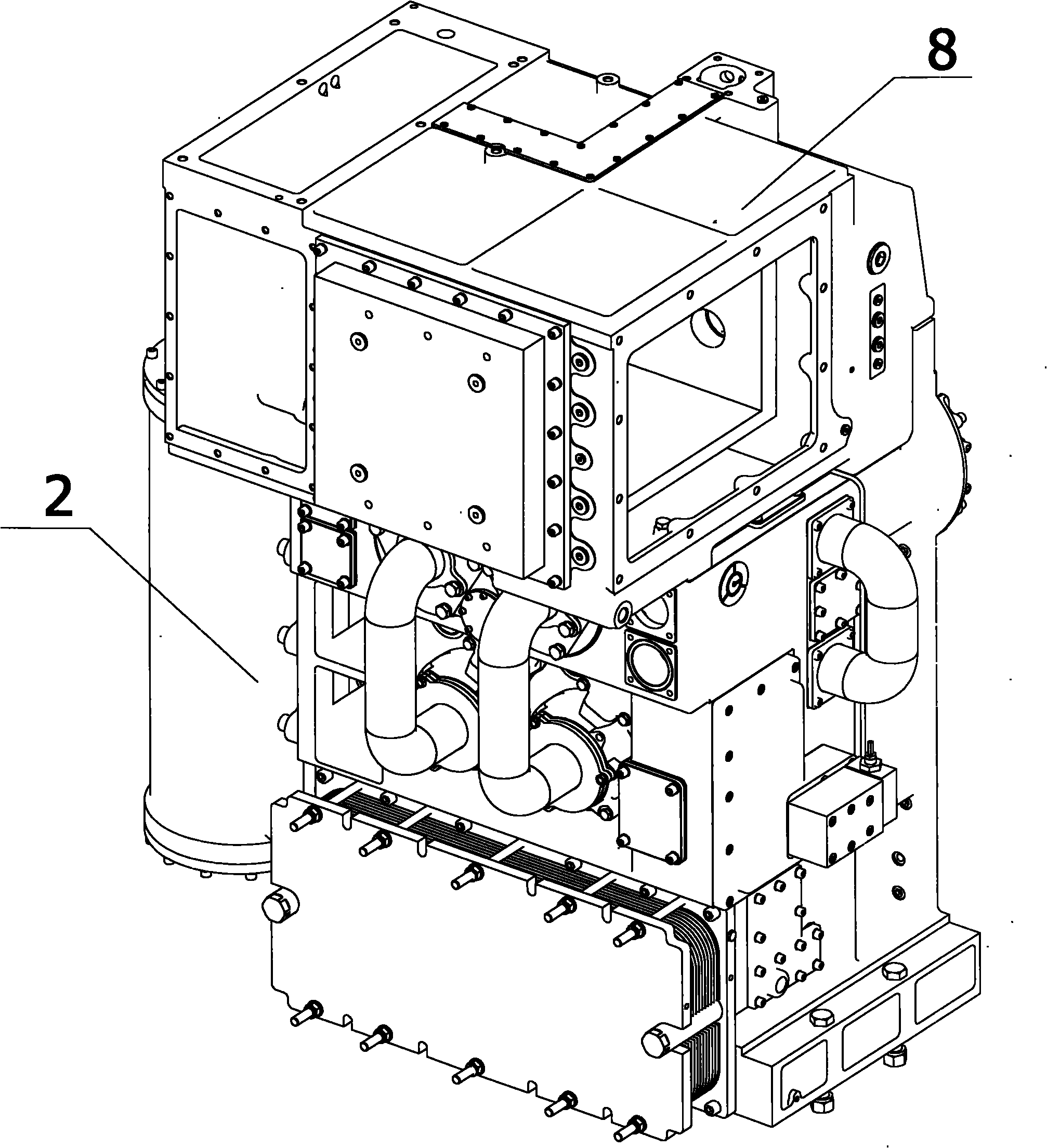

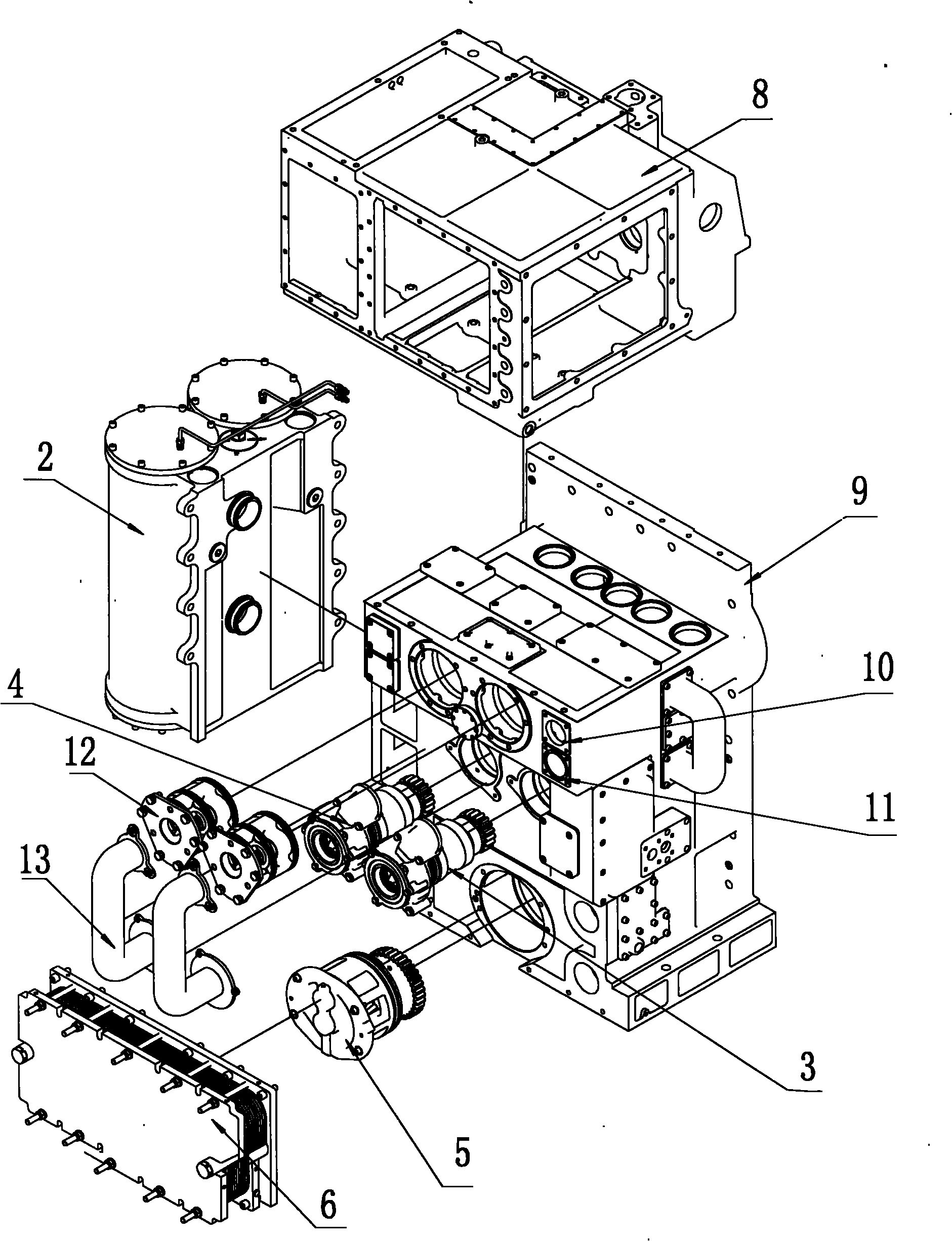

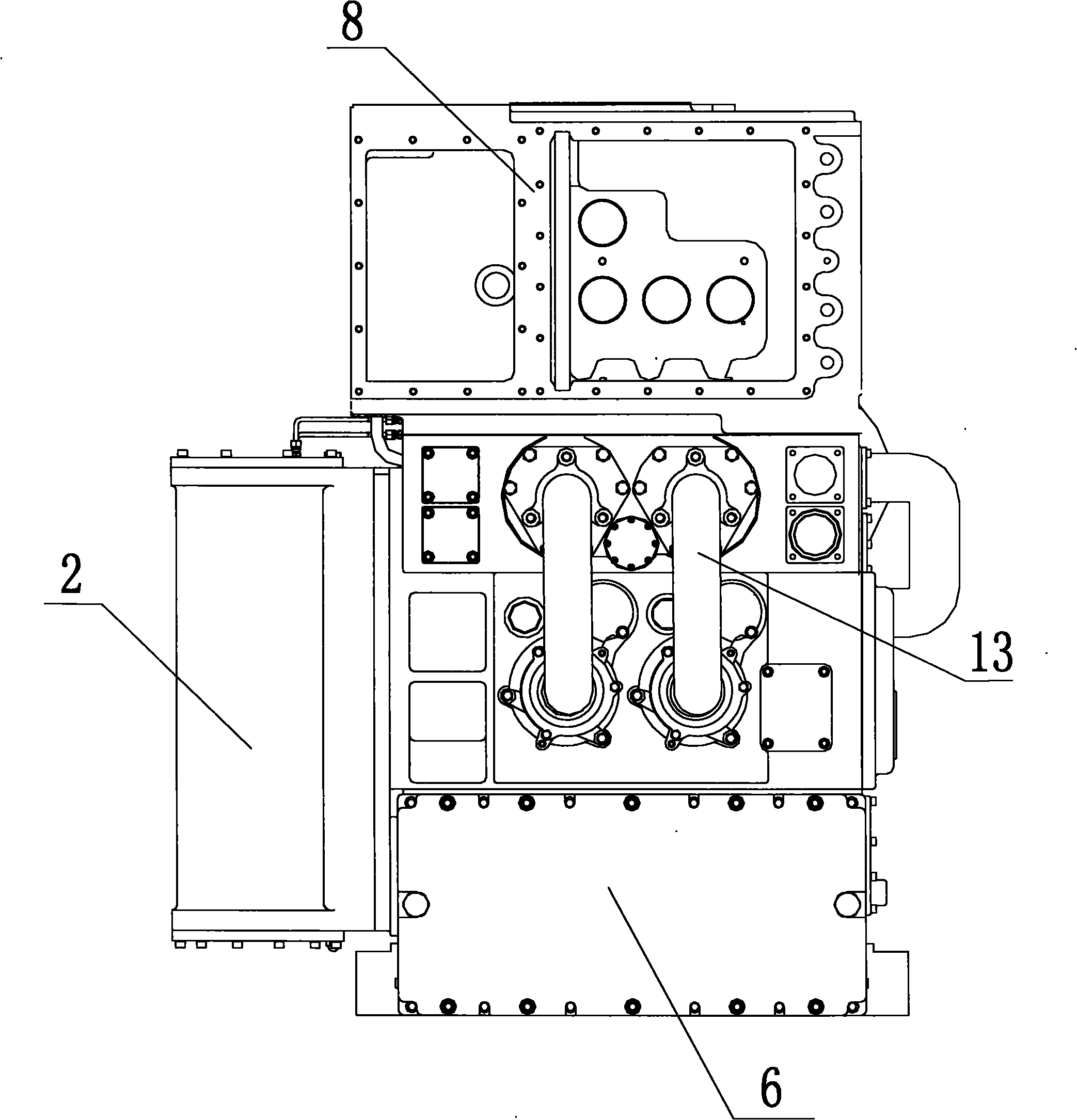

[0028] like Figure 1-13 As shown, as an embodiment of the present invention, the diesel engine auxiliary system includes a lubricating oil filter 2, a low-temperature cooling water pump 3, a high-temperature cooling water pump 4, a main oil pump 5, a lubricating oil cooler 6, and a cooling circulating water temperature control device 12 , Intercooler installation box 8 and auxiliary supporting box body 9. The back of the auxiliary support box 9 is provided with a main engine oil channel interface 111 for connecting the oil channel in the diesel engine body 1 into the auxiliary support box 9 . An external cooling water inlet 10 and an external cooling water outlet 11 connected to the diesel engine body 1 are also provided on the front upper part of the auxiliary supporting box body 9 . The front of the auxiliary supporting box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com