Vapor deposition device, vapor deposition method, and organic EL display device

A technology of evaporation and evaporation source, applied in lighting devices, vacuum evaporation coating, sputtering coating, etc., can solve the problems of difficult operation, difficulty in achieving high precision, productivity and safety obstacles, etc., and achieve high productivity. Effects of reduced reduction, excellent display quality, and excellent reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1)

[0159] Figure 5 It is a perspective view showing the basic configuration of the vapor deposition apparatus according to Embodiment 1 of the present invention. Figure 6 yes Figure 5 The shown vapor deposition device is a front sectional view along a plane passing through the vapor deposition source 60 .

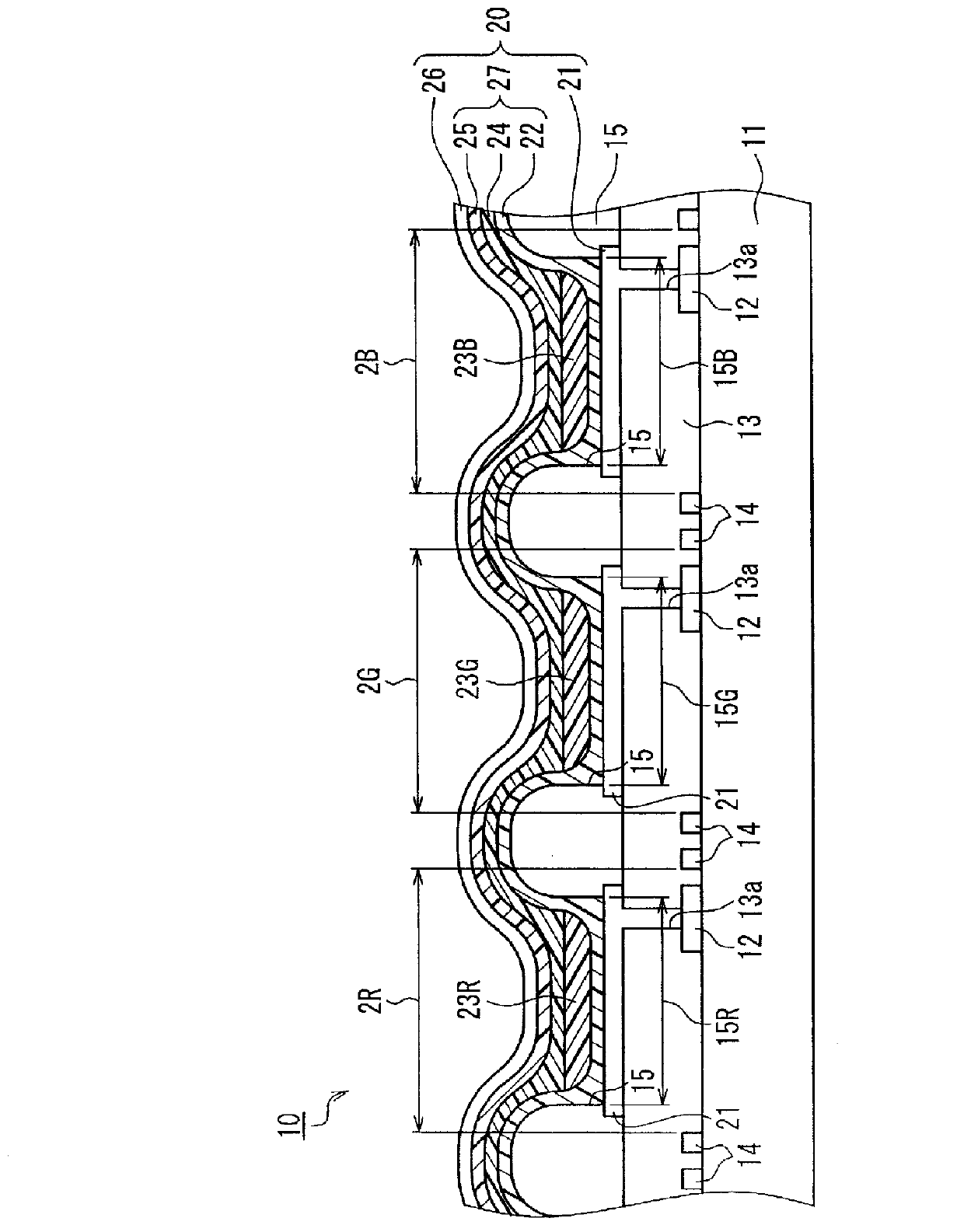

[0160] The vapor deposition unit 50 includes a vapor deposition source 60, a vapor deposition mask 70, and a limiting unit 80 disposed therebetween. The substrate 10 moves at a constant speed along the arrow 10 a on the side opposite to the vapor deposition source 60 with respect to the vapor deposition mask 70 . For the convenience of the following description, it is assumed that the horizontal axis parallel to the moving direction 10a of the substrate 10 is the Y axis, the horizontal axis perpendicular to the Y axis is the X axis, and the vertical axis perpendicular to the X axis and the Y axis It is the XYZ orthogonal coordinate system of the Z axis. The Z axis is pa...

Embodiment approach 2)

[0228]In Embodiment 1 described above, the lowermost sheet material to which the vapor deposition material 95 is attached is taken out of the vapor deposition chamber 100, and another clean sheet material is stacked on the uppermost layer sheet material. On the other hand, in Embodiment 2, when the vapor deposition material 95 adheres only to the lower surface of the lowermost sheet material, the sheet material is not taken out from the vapor deposition chamber 100 but is reversed and laminated. on the top plate.

[0229] Hereinafter, Embodiment 2 will be described focusing on differences from Embodiment 1. FIG. In the drawings referred to in the following description, components corresponding to those described in Embodiment 1 are given the same reference numerals, and their repeated descriptions will be omitted.

[0230] Hereinafter, a maintenance method for the limiting unit 80 in the vapor deposition apparatus according to Embodiment 2 will be described.

[0231] Figur...

Embodiment approach 3)

[0245] In Embodiments 1 and 2 described above, the plurality of plate materials constituting the restricting unit 80 are all the same. On the other hand, in Embodiment 3, the arrangement of the through-holes is different for each of the plurality of plate materials constituting the restricting unit 80 .

[0246] Hereinafter, Embodiment 3 will be described focusing on differences from Embodiments 1 and 2. FIG. In the drawings referred to in the following description, components corresponding to those described in Embodiment 1 are given the same reference numerals, and their repeated descriptions are omitted.

[0247] In order to simplify the description, Embodiment 3 will be described using an example in which the limiting unit 80 includes three plates.

[0248] Figure 14 It is a partial plan view of three plates 831 , 832 , and 833 constituting the confinement unit 80 of the vapor deposition apparatus according to the third embodiment. The plates 831 , 832 , and 833 have t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com