Process for producing substrate with metal wiring

A manufacturing method and metal wiring technology, applied in the field of substrate manufacturing, can solve the problems of complicated operation and difficulty in forming shapes, and achieve the effect of low-cost productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

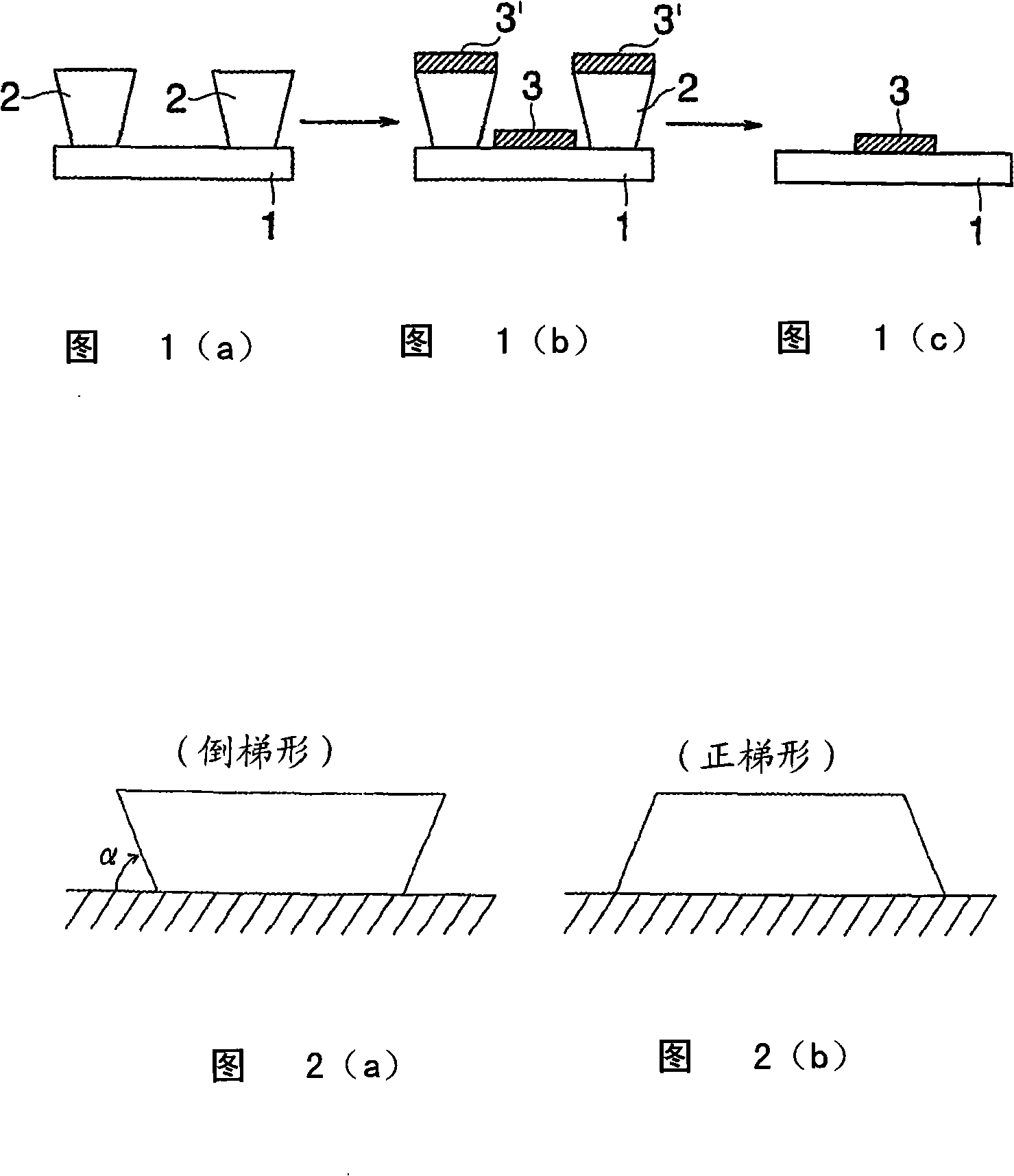

Method used

Image

Examples

Embodiment 1

[0105] (1) Preparation of positive photosensitive resin composition

[0106]Mix the following components to obtain a positive-type photosensitive resin composition (resist solution). The components are: mixed cresol (mass mixing ratio=5:5) of m-cresol / p-cresol and formaldehyde in oxalic acid 17.7 parts by mass of novolak resin (weight-average molecular weight=about 5500) obtained by polycondensation in the presence of 2,3,4,4'-tetrahydroxybenzophenone and 1,2-naphthoquinonediazide-5 - Siloxane-based surfactant "SH29PA" having a siloxane bond with 4.3 parts by mass of a quinonediazide group-containing compound having a sulfonyl chloride esterification rate of 70 mol% [Toray Dow Corning Siriko 107.4 parts by mass of 107.4 parts by mass of 107.4 parts by mass of propylene glycol monomethyl ether acetate (PGMEA) manufactured by Iln Co., Ltd.

[0107] (2) Formation of an inverted trapezoidal resist pattern

[0108] The resist solution obtained in the above (1) was coated on a gla...

Embodiment 2、3

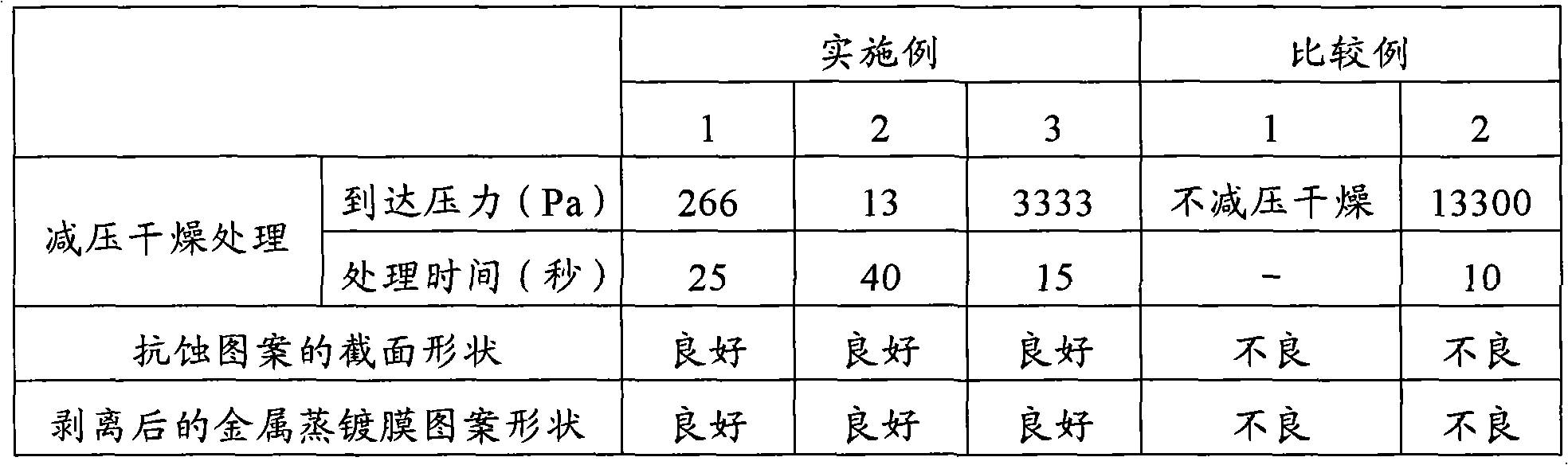

[0114] Metal wiring-attached substrates were respectively obtained in the same manner as in Example 1 except that the attained pressure at the time of reduced-pressure drying was changed.

[0115] Table 1 shows the evaluation results of the attained pressure and treatment time during the reduced-pressure drying treatment, the cross-sectional shape of the resist pattern, and the shape of the metal vapor-deposited film pattern after peeling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com