Aluminum foil surface residual oil pretreatment temperature control purging device and use method and application thereof

A pretreatment, aluminum foil technology, applied in workpiece surface treatment equipment, metal processing equipment, metal rolling, etc., can solve problems such as insufficient oil removal, reduce accidents, increase furnace temperature, and reduce preheating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

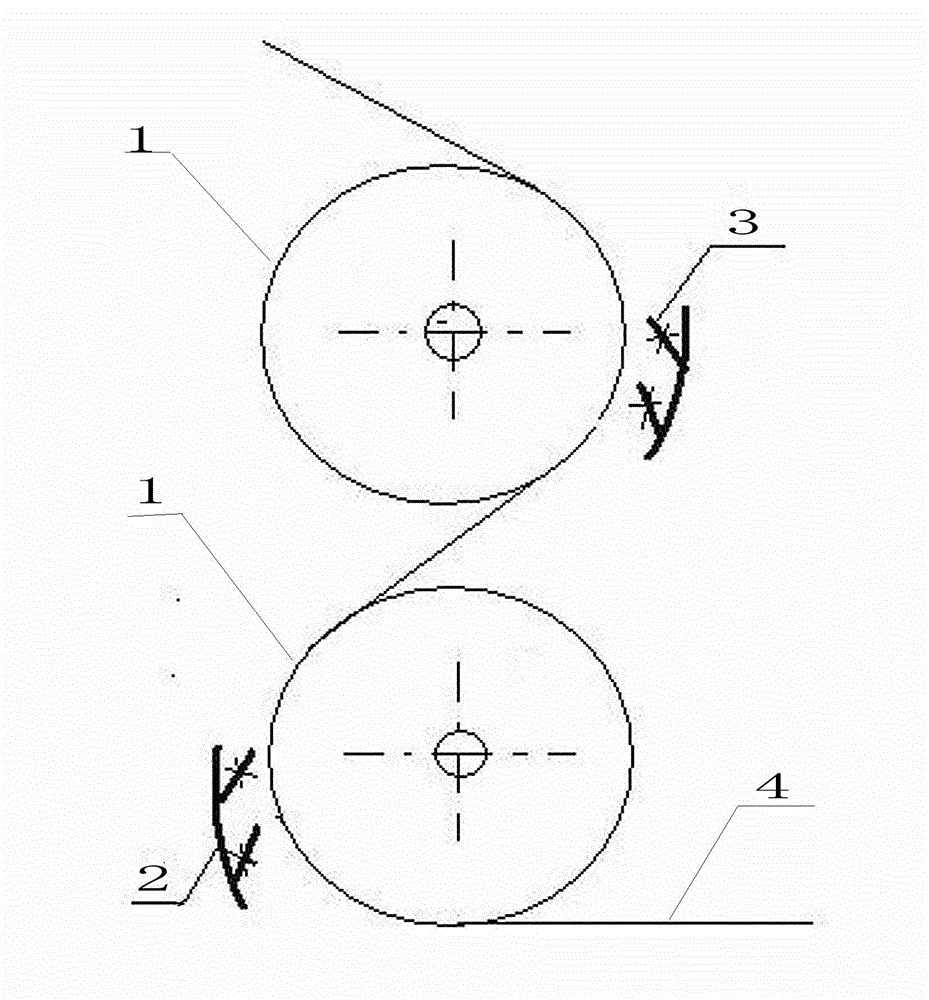

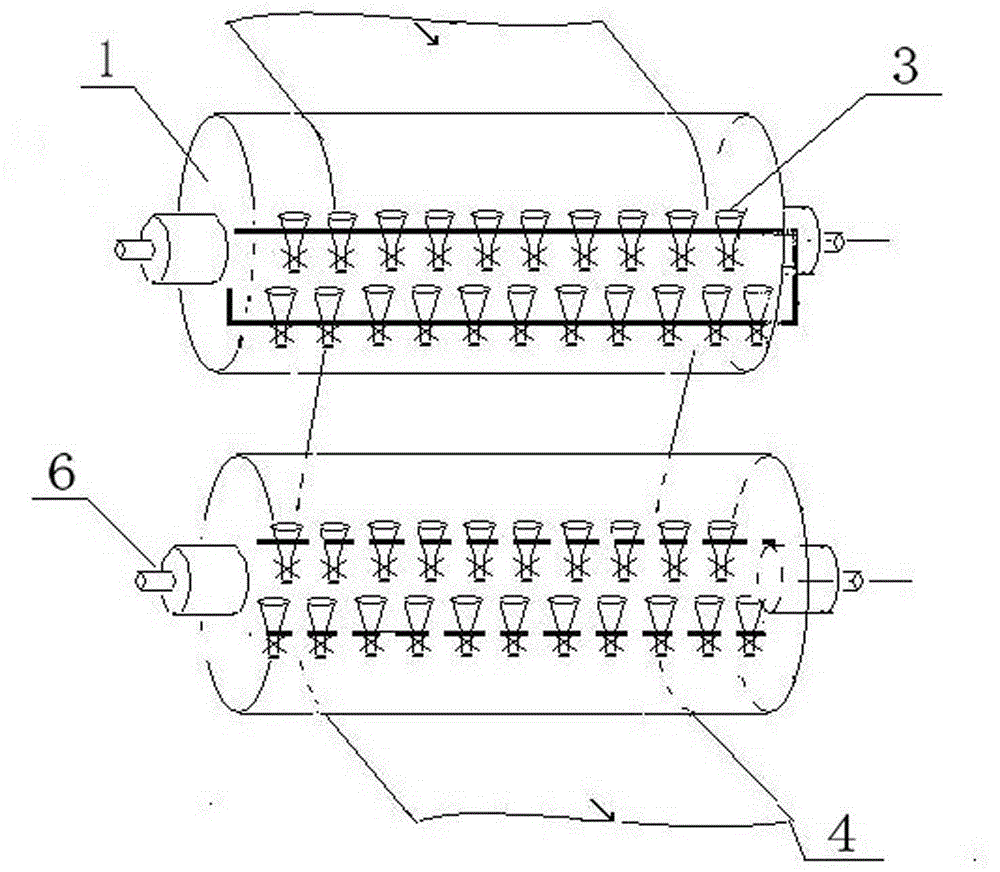

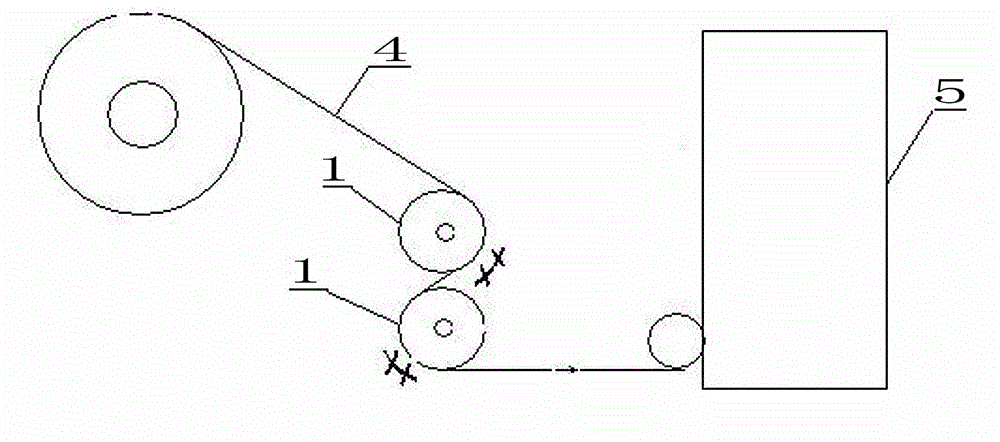

Method used

Image

Examples

Embodiment 1

[0042] The size of the incoming material is 7μm*1000㎜, 3 tons of rolls. The inspection shows that there is oil visible to the naked eye on both sides, and the width of the residual oil area is about 20cm. The slit products belong to users with high requirements for degreasing quality. Before starting the machine, set the surface temperature of the guide roller to 60°C, the uncoiling speed to 300m / min, and the outlet temperature of the tuyere to about 40°C. After hot air blowing, the oily areas on both sides are reduced to within 3cm, and the oily traces are also significantly reduced. The total annealing time is set to 75h, which is 25h less than the original process. Inspection after release from the furnace: the water brushing test is A-level, which is equivalent to the original process, and there is no obvious difference. There is no abnormality in the 3cm residual area visible to the naked eye after treatment. The situation is normal compared with the original process.

Embodiment 2

[0044] The incoming material specification is 9μm*960㎜ roll 2.5 tons, the inspection shows that the entire foil surface has oil visible to the naked eye, and the slit products belong to users with high requirements for degreasing quality. Before starting the machine, set the surface temperature of the heat guide roller to 55°C, the air outlet temperature of the tuyere to about 40°C, and the uncoiling speed to 350m / min. After hot air blowing, the size of the residual oil on the entire foil surface is reduced to 2-3cm sporadic dots, and the traces of oil are significantly reduced. The total annealing time is set to 70h, 20h less than the original process. Inspection after release from the furnace: the water brushing test is grade A, which is equivalent to the original process. No oil spots are found on the entire annealed aluminum foil surface.

Embodiment 3

[0046] The incoming material specification is 6.3μm*880㎜ roll 3.5 tons. This specification is produced for Tetra Pak users. It is a large roll diameter product. The user has higher requirements for degreasing and surface roughening. The inspection shows that there is oil visible to the naked eye on one side of the foil surface, and the slit products belong to users with higher requirements for degreasing quality. Before starting the machine, set the surface temperature of the thermal guide roller to 60°C, the outlet air temperature to about 45°C, and the uncoiling speed to 380m / min. After hot air blowing, the residual oil on the foil surface becomes 2-3cm sporadic spots, and the traces of oil are significantly reduced. The total annealing time is set to 80h, 15h less than the original process. Out of the furnace inspection: the water spray test is grade A, and there is no obvious difference in the degreasing effect from the original process, and no oil spots that have not bee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com