Production method of bainite cold forging steel wire rod

A production method and technology of cold heading steel, applied in the field of steel rolling, can solve problems such as long spheroidization time, uneven cementite distribution, uneven cooling, etc., and achieve the effect of simplifying annealing and shortening annealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

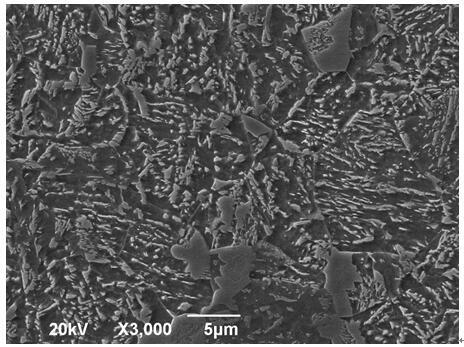

[0027] Embodiment 1: Production method of Φ6.5mm SCM435 steel

[0028] The chemical composition of the steel is shown in Table 1. Process steps include:

[0029] (1) The 150mm×150mm continuous casting slab is inspected and ground and heated to 1020-1060°C. After 30 passes of continuous rolling, the wire rod with a diameter of 6.5mm is obtained. The temperature of the incoming wire rod reducing and sizing unit is controlled at 800-1000 830°C range;

[0030] (2) After rolling, the water tank is rapidly cooled to 750-780°C for silk spinning, and it runs at a speed of 0.36-0.73m / s on the loose-coil cooling conveyor line, and passes through ferrite phase transformation at an average cooling speed of 5°C / s. After the interval (675-515°C), it enters the heat preservation cover and cools slowly to about 420°C, and then rolls are collected.

[0031] (3) Put the wire rod into the annealing furnace, heat it to 770°C for 2 hours, cool it to 720°C at a cooling rate of 20°C / h, and then c...

Embodiment 2

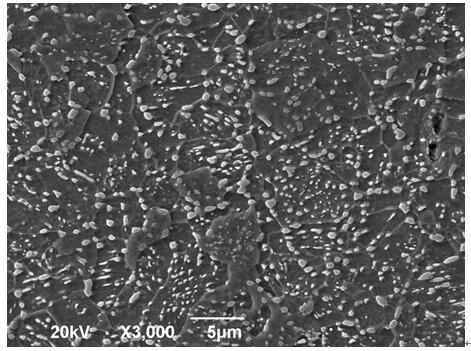

[0032] Embodiment 2: the production method of Φ9.0mmSCM435 steel

[0033] The chemical composition of the steel is shown in Table 1. Process steps include:

[0034] (1) The 150mm×150mm continuous casting slab is inspected and ground, heated to 1020-1060°C, and the wire rod with a diameter of 9.0mm is obtained through 28 continuous rolling passes, and the temperature of the incoming wire rod reducing and sizing unit is controlled at 785-1 815°C range;

[0035] (2) After rolling, the water tank is rapidly cooled to 750-770 ℃ for silk spinning, and the coil cooling conveyor line runs at a speed of 0.41-0.85m / s, and the average cooling rate of 5 ℃ / s passes through ferrite phase transformation After the interval (675-515°C), it enters the heat preservation cover and slowly cools down to about 440°C, and then rolls are collected.

[0036] (3) Put the wire rod into the annealing furnace, heat it to 770°C for 2 hours, cool it to 720°C at a cooling rate of 20°C / h, and then cool it t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com