High-temperature annealing method for manufacturing silicon carbide device

A high-temperature annealing, silicon carbide technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effects of low production cost, shortened process time, and reduced annealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

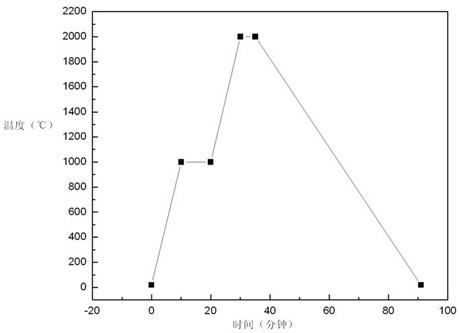

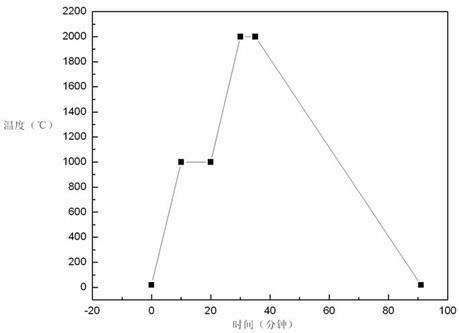

[0020] With reference to the accompanying drawings,

[0021] 1) Use a mixed solution of hydrochloric acid and nitric acid (the weight ratio is 1:1) to clean the ion-implanted SiC wafer, type 4H-SiC;

[0022] 2) Coating a layer of ArF photoresist on the SiC wafer as a protective layer;

[0023] 3) Put the SiC wafer into a high-temperature annealing furnace, and fill it with argon as a protective gas;

[0024] 4) Set the pressure of the high-temperature annealing furnace to 10Pa, heat the SiC wafer to 1000°C for the first time, and heat up at a rate of 100°C / min, keep the temperature for 10 minutes, and carbonize the protective layer;

[0025] 5) Set the pressure of the high-temperature annealing furnace to 1000Pa, heat the SiC wafer for the second time, from 1000°C to 2000°C, with a heating rate of 100°C / min, keep the temperature for 1 minute, and perform high-temperature annealing;

[0026] 6) Set the pressure of the high-temperature annealing furnace to 2000Pa, and cool dow...

Embodiment 2

[0028] Referring to the accompanying drawings,

[0029] 1) Clean the ion-implanted SiC wafer with sulfuric acid, then clean the ion-implanted SiC wafer with hydrochloric acid, type 6H-SiC;

[0030] 2) Coating a layer of electron beam photoresist on the SiC wafer as a protective layer;

[0031] 3) Put the SiC wafer into a high-temperature annealing furnace, and fill it with argon as a protective gas;

[0032] 4) Set the pressure of the high-temperature annealing furnace to 0.0001Pa, heat the SiC wafer for the first time to 850°C, the heating rate is 80°C / min, and keep the temperature for 30 minutes to carbonize the protective layer;

[0033] 5) Set the pressure of the high-temperature annealing furnace to 500Pa, heat the SiC wafer for the second time, from 850°C to 1850°C, with a heating rate of 200°C / min, keep the temperature for 5 minutes, and perform high-temperature annealing;

[0034] 6) Set the pressure of the high-temperature annealing furnace to 1000Pa, and cool the S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com