Method for quickly preparing monoclinic phase VO2

A VO2, monoclinic phase technology, applied in vanadium oxide and other directions, can solve the problems of difficult to obtain VO2 pure phase, high cost, and increased preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

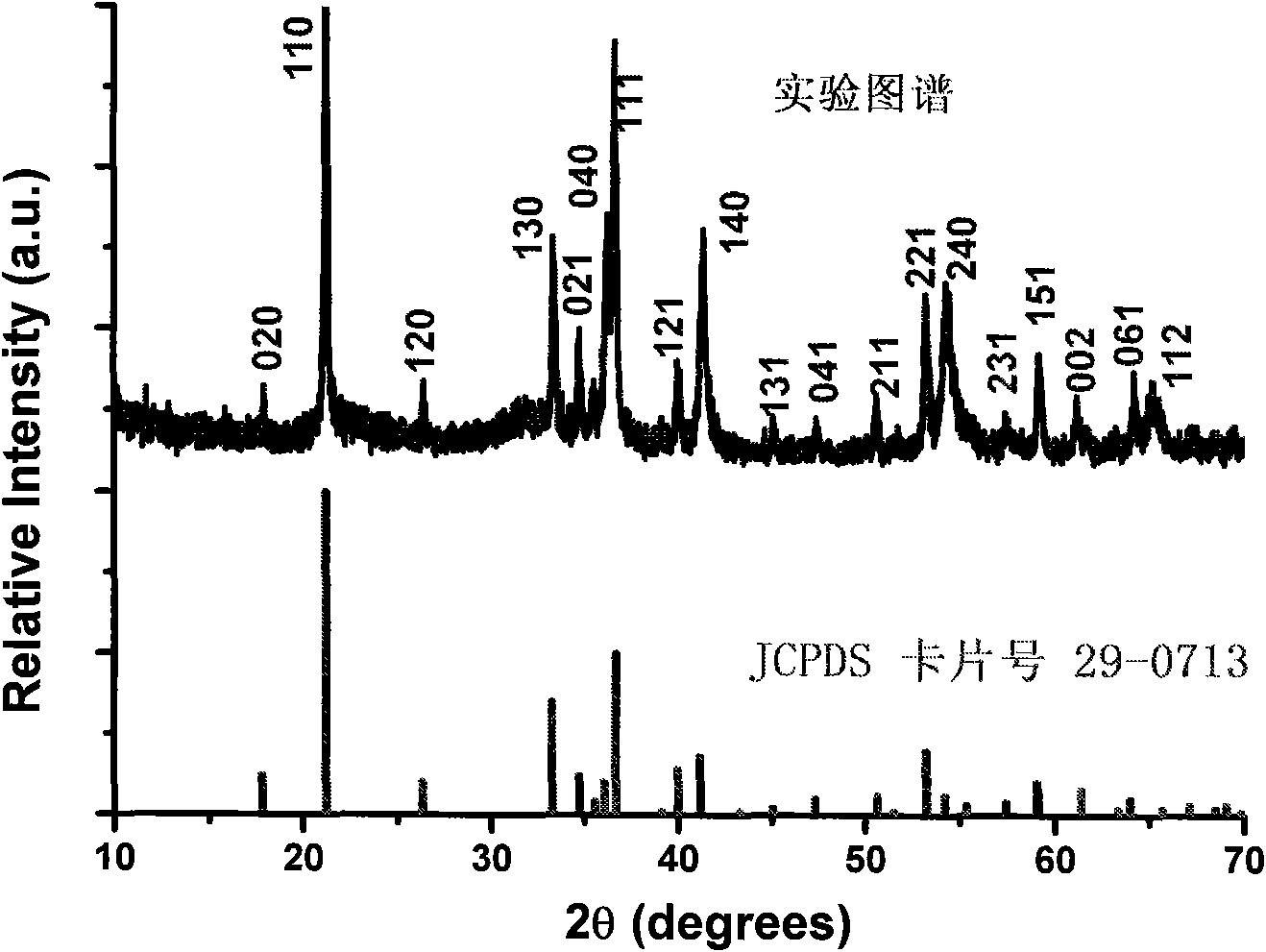

[0043] Embodiment 1: with VO 2 (B) Preparation of VO 2 (M)

[0044] 1) In a polytetrafluoroethylene reactor with a volume of 50mL, add 2mmol V 2 o 5 and 40 mL of distilled water, and adjust the pH value to 3-4 with 10% HCOOH aqueous solution. After stirring for 30 minutes, put it into a kettle shell and seal it, then keep it at 200°C for 12 hours, and after natural cooling, collect the product by centrifugation to obtain VO 2 (B).

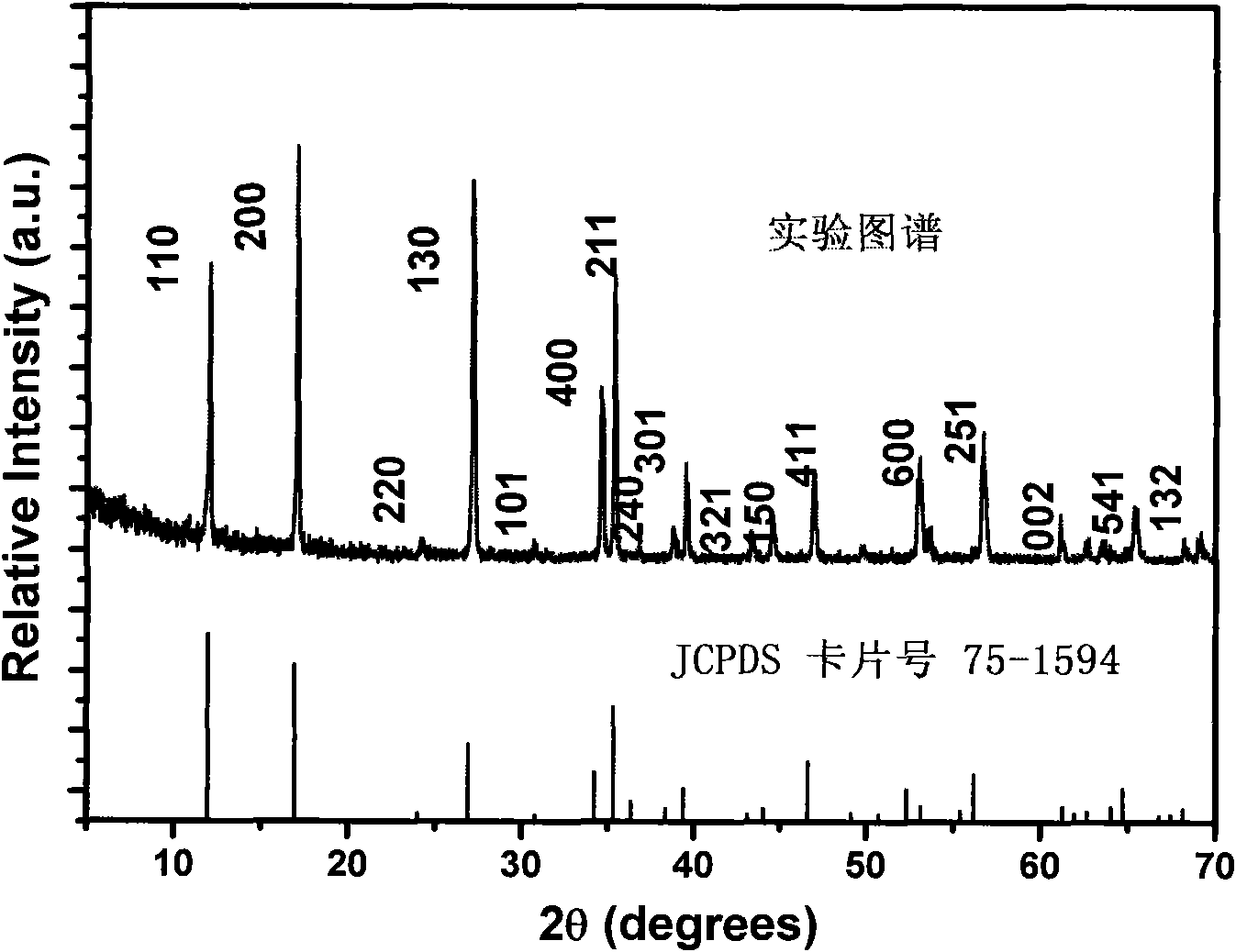

[0045] 2) Will contain 0.5g VO 2 (B) The porcelain boat is placed with N 2 in a tube furnace, and annealed at 450°C for 12h, and after cooling, VO with a purity of 100% was obtained 2(M). The XRD spectrum and DSC cycle spectrum of this compound and Figure 4 and Figure 5 No substantial differences are shown. It can be seen from the figure that the structure of the compound is correct.

Embodiment 2

[0046] Embodiment 2: use phase A VO 2 (A) Preparation of VO 2 (M)

[0047] 1) Add 2mmol VO(acac) to a polytetrafluoroethylene reactor with a volume of 50ml 2 (Vanadium acetylacetonate complex) and 40mL of distilled water, and adjust the pH value to 3-4 with a 10% HCOOH aqueous solution by mass percentage, after stirring for 30min, put it into a kettle shell and seal it, and then keep it at 220°C for 12h. After natural cooling, the product was collected by centrifugation to obtain phase A VO 2 (A).

[0048] 2) Will contain 0.5g VO 2 The porcelain boat of (A) is placed through the N 2 in a tube furnace, and annealed at 450°C for 12h, and after cooling, VO with a purity of 100% was obtained 2 (M). The XRD spectrum and DSC cycle spectrum of this compound and Figure 4 and Figure 5 No substantial differences are shown. It can be seen from the figure that the structure of the compound is correct.

Embodiment 3

[0049] Embodiment 3: with VO 2 (P) Preparation of VO 2 (M)

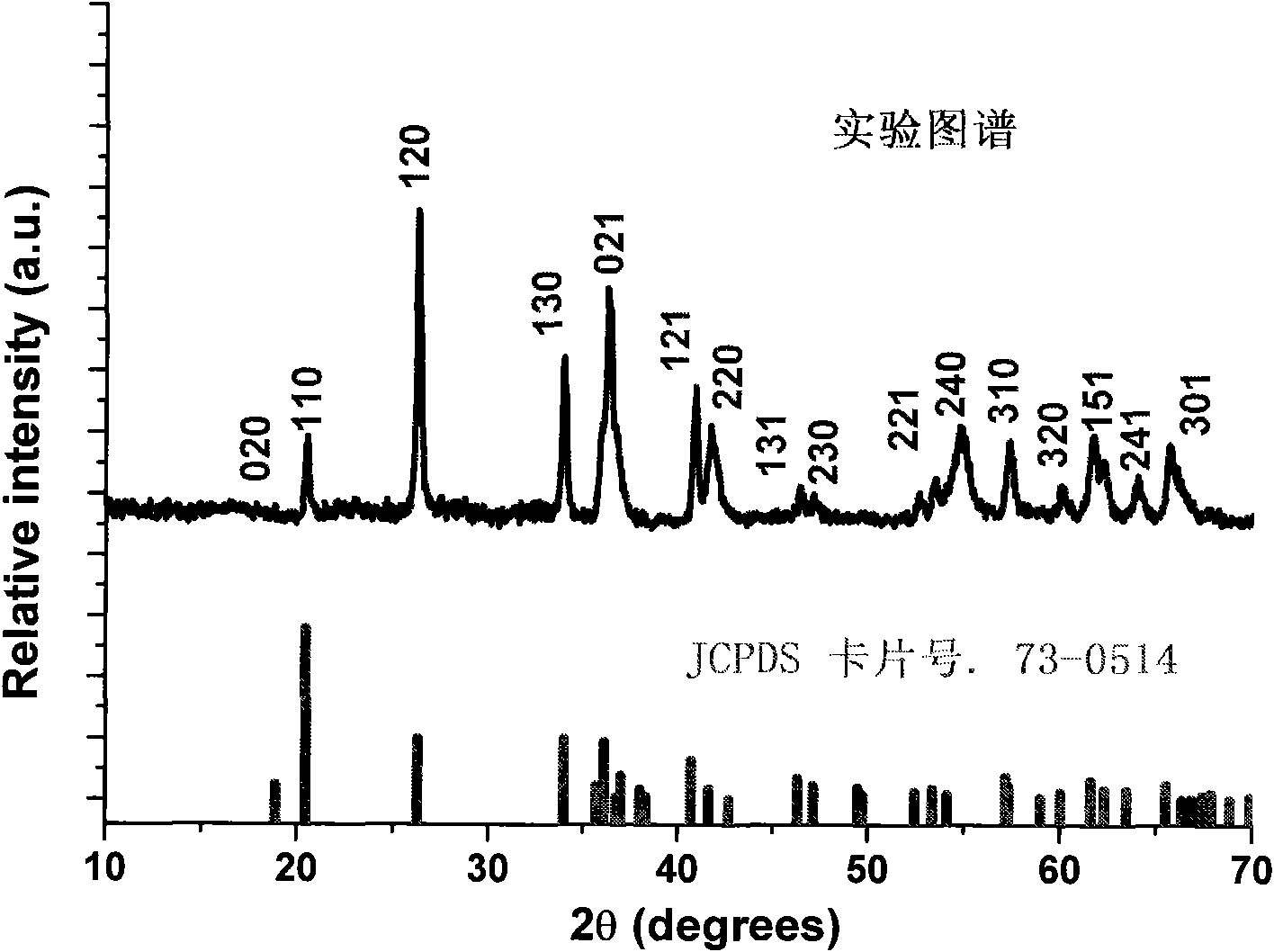

[0050] 1) In a polytetrafluoroethylene reactor with a volume of 50ml, add 4mmol Na 3 VO 4 12H 2 O (sodium orthovanadate), 20mmol TAA (thioacetamide) and 50ml distilled water, after stirring for 30min, put them into the kettle shell, then keep at 200°C for 12h, after natural cooling, centrifuge to collect the product to obtain VO 2 (P), the XRD spectrum of this compound is as figure 1 shown. It can be seen from the figure that the structure of the compound is correct.

[0051] 2) Will contain 0.5g VO 2 The porcelain boat of (P) is placed with N 2 in a tube furnace, and annealed at 400°C for 1 minute, and after cooling, VO with a purity of 100% was obtained 2 (M). The compound VO 2 The XRD spectrum and DSC cycle spectrum of (M) are respectively Figure 4 and Figure 5 shown. It can be seen from the figure that the structure of the compound is correct.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com