Production process of hot-dip aluminum-zinc steel plate

A production process and hot-dip aluminum technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of low tensile strength, increase production cost, reduce work efficiency, etc., and achieve shortened annealing. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

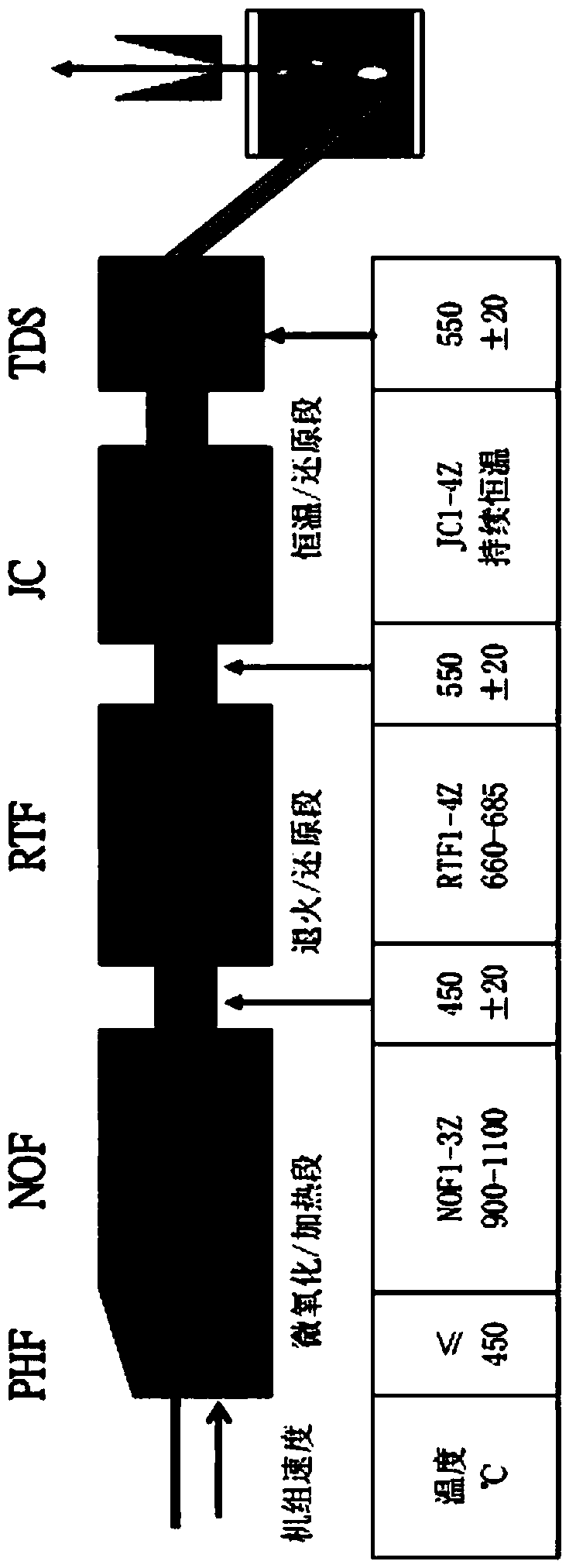

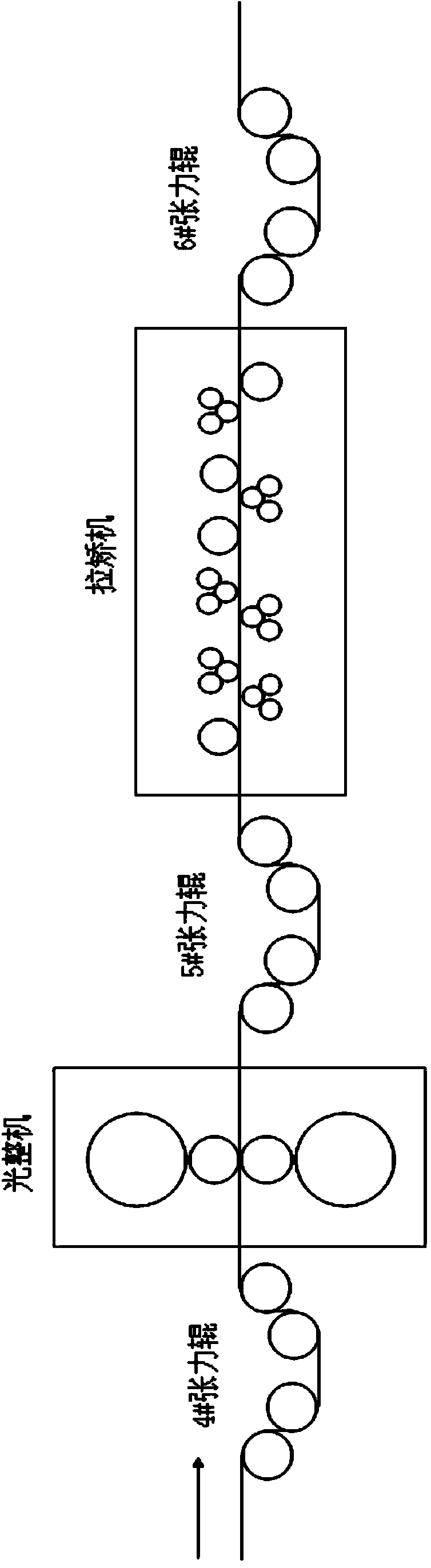

[0019] Such as figure 1 , figure 2 and image 3 As shown, the present invention takes the production of galvanized SGLC570 products, hot-dip galvanized coils with a specification of 0.38*1000mm as an example. The selected raw material is cold-rolled steel plate; the equipment used is a conventional galvanizing unit, including uncoiling equipment, welding machine, cleaning section, improved Sendzimir annealing furnace, plating tank, air knife, rear cooling device, skin pass machine, Tension straightening machine, roller coating machine, infrared drying device and coiling machine; its technological process: coiling-uncoiling (1# and 2# uncoiler work alternately)-shearing (double-layer shearing)-welding-dipping and scrubbing Rinsing and drying (cleaning section) - entrance loop - reduction annealing (annealing furnace) - hot dipping (plating bath) - air knife scraping - air cooling, water quenching cooling (post cooling) - finishing - tension leveling -passivation / fingerprint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com