Manufacturing method for amorphous alloy core used for motor and transformer

A technology for amorphous alloys and transformers, which is applied in the field of preparation of amorphous alloy iron cores, and can solve problems such as difficulty in using press forming and argon arc welding shaping processes, low efficiency, and high requirements for molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

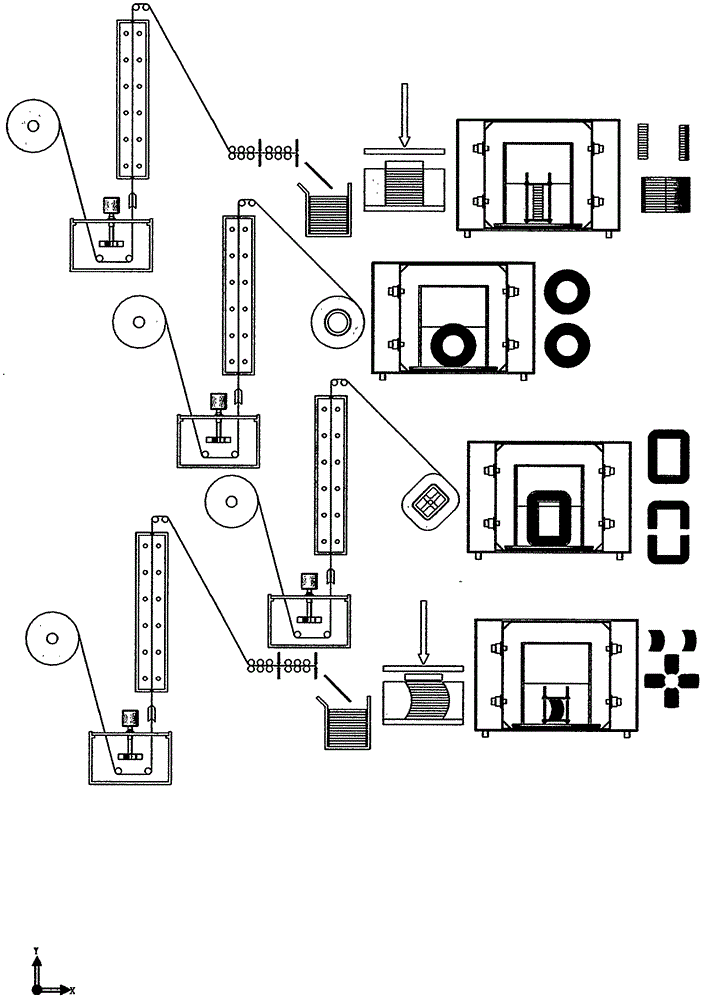

[0053] Embodiment 1 Preparation steps of radial flux motor amorphous alloy iron core :

[0054] Such as Figure 5 As shown, the amorphous alloy strip is coated, dried, cut, and linearly pressed to form an integral linear laminated iron core blank. In the figure, the strip disk 1 equipped with a brake, the amorphous alloy strip 2, the coating tank 3, the binder coating 4, the guide roller 5 in the tank, the agitator 6, the agitator motor 7, the coating tank cover plate 8, Squeegee plate 9, oven 10, heating pipe 11, guide roller 12 above the oven, nip roller 13, rolling shear cutting position 14, cutting detection position 15, strip sheet falling after cutting 16, strip sheet collecting box 17, collecting Strip laminate 18, linear laminate 20, pressing force 21, pressing plate 22, pressing table 23, upper pressing iron 24, side dies 25 and 26.

[0055] The composition of the inorganic insulating high temperature resistant binder is (weight %): SiO 2 : 12%, Al 2 o 3 : 13%,...

Embodiment 2

[0062] Example 2 Preparation Steps of Amorphous Alloy Iron Core for Transverse Flux Motor :

[0063] Such as Figure 8 As shown, the amorphous alloy strip is coated, dried, cut, and arc pressed to form an integral arc laminated iron core blank. In the figure, the arc laminated body 30, the pressing force 31, the upper pressing plate 32, the pressing table 33, the upper pressing iron 34, and the side arc pressing dies 35 and 36.

[0064] The composition (% by weight) of the inorganic insulating high-temperature-resistant adhesive for coating is the same as that of Example 1.

[0065] The iron core of a transverse flux machine is usually segmented by phase, and the individual iron cores of the stator or rotor in each phase segment are discrete and arranged in a circular array. The arc pressing of the laminate is to reduce the waste of material in the subsequent cutting process. The arc pressing of the amorphous alloy sheet laminate usually adopts a circular arc with the sam...

Embodiment 3

[0071] Embodiment 3 Preparation steps of amorphous alloy iron core of axial flux motor:

[0072] Such as Figure 11 As shown, the amorphous alloy strip is coated, dried, and tightly wound to form a torus core blank. In the figure, a torus core blank 40 and an inner ring fixture 41 of the torus core blank.

[0073] The composition (weight %) of the inorganic insulating high temperature resistant adhesive is the same as that of Example 1.

[0074] The temperature of the oven is set at 80°C, and the surface of the strip passing through the oven can retain a certain degree of viscosity, which is convenient for winding. Increase the braking force of the strip disc 1 to realize the tight winding of the torus core blank. Continuous tight winding, the strip winding speed is 1m~1.5m / s.

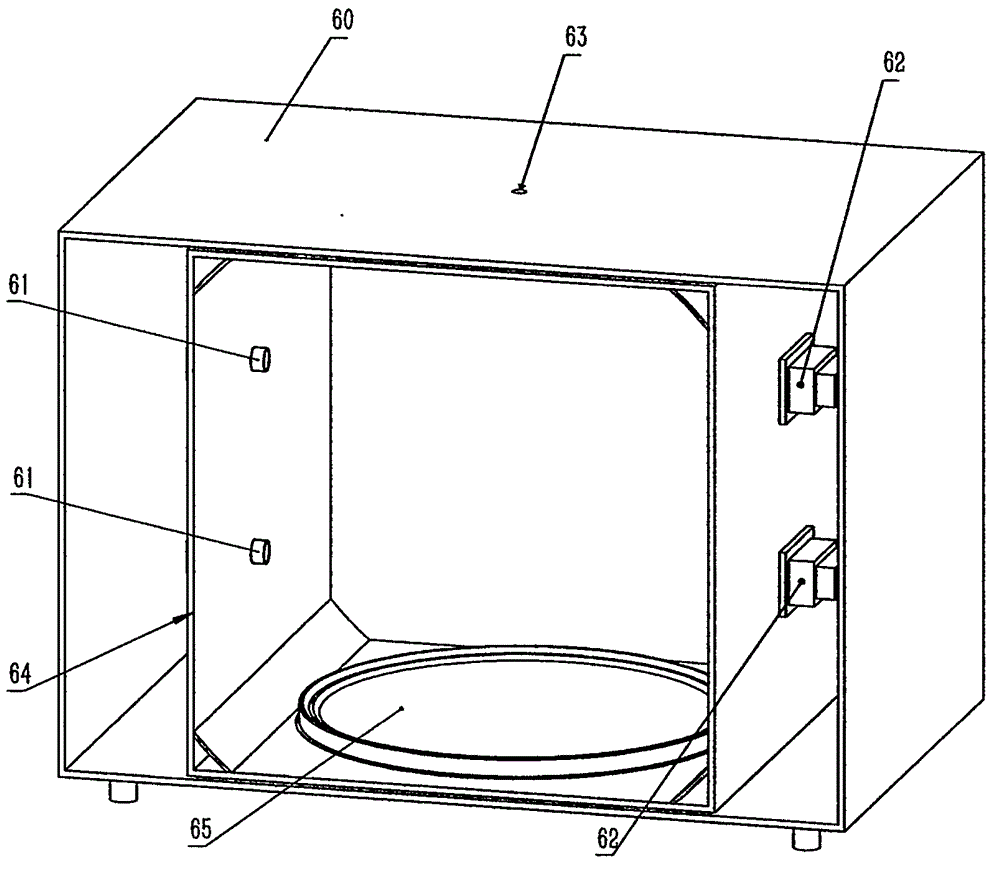

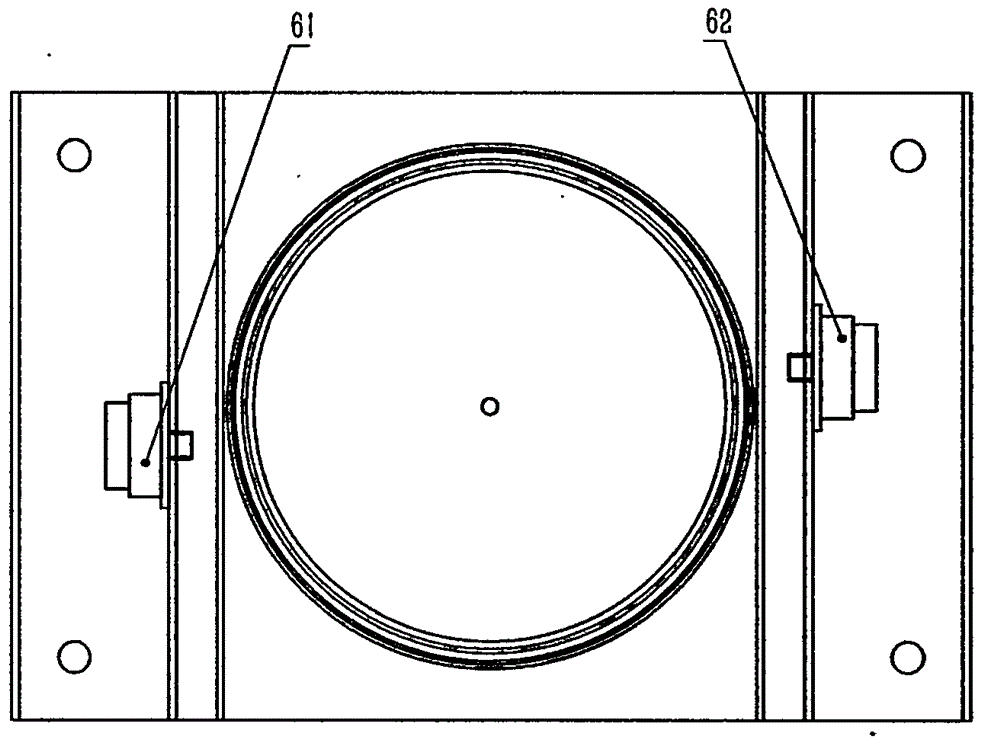

[0075] Such as Figure 12 As shown, the torus iron core blank and its fixing fixture in the microwave oven. In the figure, a circular iron core blank 40, an inner ring fixture 41 of the circula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com