Beta zeolite-containing ultradeep hydrodesulfurization catalyst and preparation method thereof

A desulfurization catalyst and deep hydrogenation technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of reduced reaction rate, difficult access to active centers, difficult removal, etc., to achieve pore size increase, Reduce the cost of preparation and improve the effect of pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

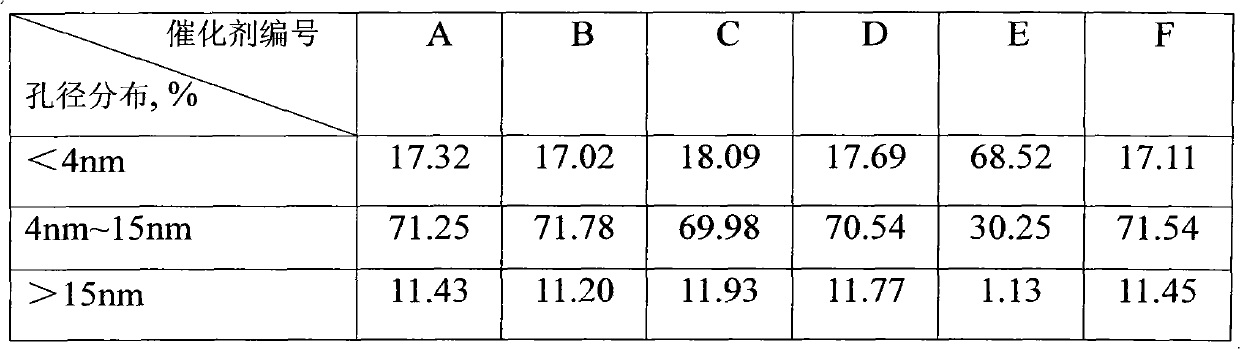

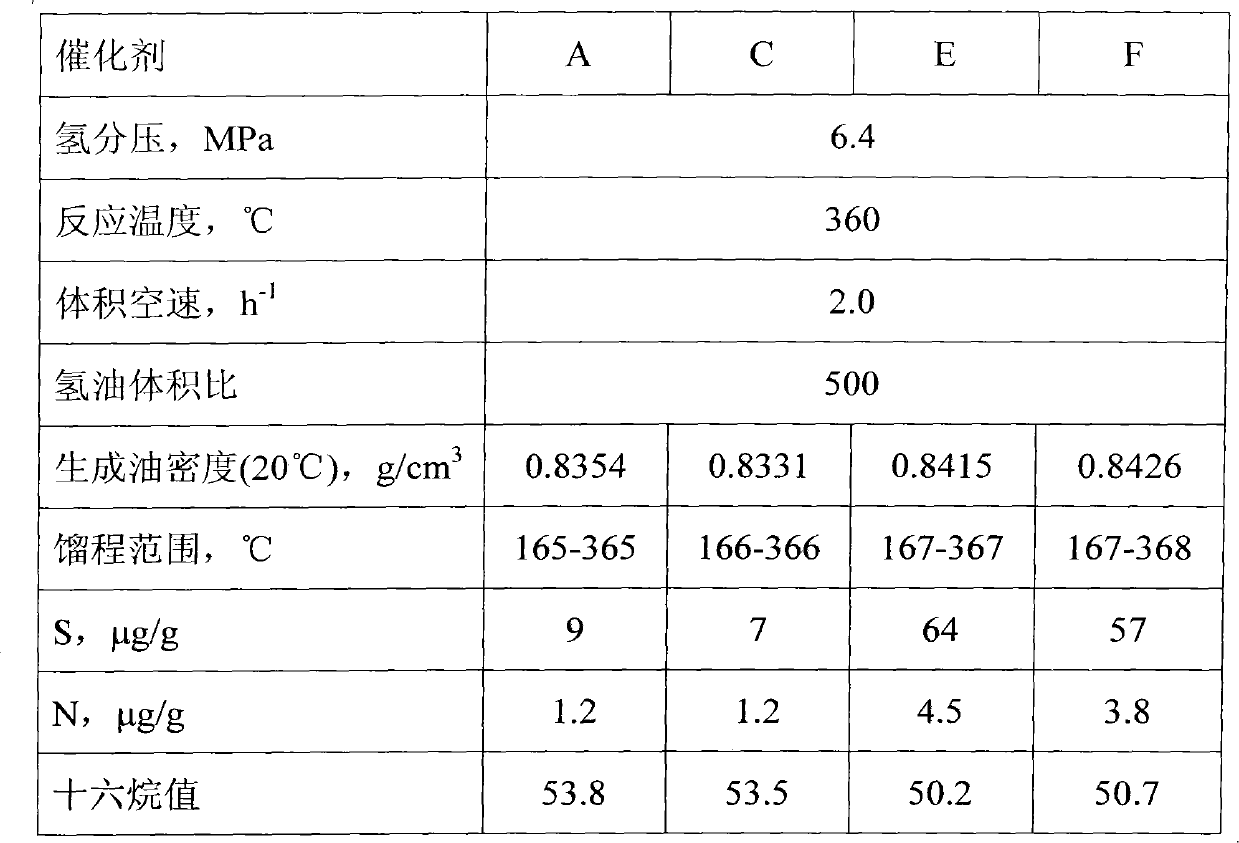

[0031] Add 1000 mL of water to the dissolution tank, add 43 g of nickel chloride to dissolve, 36.5 g of ammonium metatungstate to dissolve, and 357 ml of aluminum chloride solution, and mix them to form a solution. Take 160 g of ammonium bicarbonate to prepare an aqueous solution with a molar concentration of 2.5 mol / l. Then the mixed solution, ammonium bicarbonate aqueous solution, and 10% ammonia water as a precipitating agent are simultaneously added into a reaction tank filled with purified water to form a gel. The gelation pH is 8.0 and the gelation temperature is 60°C. After gelation, 10 grams of β zeolite slurry was added and aged for 2 hours. After aging, filter, add 600ml purified water and 8.4g molybdenum trioxide to the filter cake, beat and stir evenly, filter, the filter cake obtained is dried at 80℃ for 5 hours, then extruded, washed with pure water 3 times, the wet bar is at 120 After drying at ℃ for 5 hours and calcining at 500 ℃ for 4 hours, the final catalyst...

Embodiment 2

[0033] According to the method of Example 1, according to the composition ratio of the catalyst B in Table 2, aluminum chloride, nickel chloride, sodium tungstate, and water glass were added to the dissolving tank, and the solution was mixed uniformly. Take 100 g of ammonium bicarbonate to prepare a solution with a molar concentration of 2.0 mol / l. Then the mixed solution, ammonium bicarbonate aqueous solution, and 9% ammonia water as a precipitating agent are simultaneously added into a reaction tank filled with purified water to form a gel. The gelation pH is 10 and the gelation temperature is 80°C. After gelation, add 14 grams of β zeolite slurry, age for 3 hours, filter after aging, add 600ml of purified water and 7.2g of molybdenum trioxide to the filter cake, beat the slurry and stir evenly, filter, and dry the filter cake at 70°C for 7 hours. Then the bar was extruded and washed twice with clean water. The wet bar was dried at 100°C for 6 hours and calcined at 550°C for ...

Embodiment 3

[0035] According to the method of Example 1, add nickel nitrate, ammonium metatungstate, aluminum chloride, phosphoric acid, and zirconium oxychloride to the dissolution tank according to the component content ratio of catalyst C in Table 1, and mix them to form a solution . Take 120 g of ammonium oxalate to prepare a solution with a molar concentration of 1.8 mol / l. Then, the mixed solution, ammonium oxalate aqueous solution, and 12% ammonia water as a precipitating agent were simultaneously added into a reaction tank filled with purified water to form a gel. The gelation pH was 11.0 and the gelation temperature was 60°C. After gelation, add 10 grams of β zeolite slurry, age for 2 hours, filter after aging, add 600ml purified water and 9.5g molybdenum trioxide to the filter cake, beat the slurry and stir well, filter, and dry the filter cake at 120°C for 1 hour. Then the bar was extruded into shape, the wet bar was dried at 130°C for 3 hours, and calcined at 600°C for 3 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com