Method for producing lead belt of battery plate

A storage battery and pole plate technology, which is applied in the direction of lead-acid battery electrodes, etc., can solve the problems of slow increase rate of special grain boundaries, complex production process, high annealing temperature, etc., and achieve the effect of shortening the production cycle, simple production process and short annealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

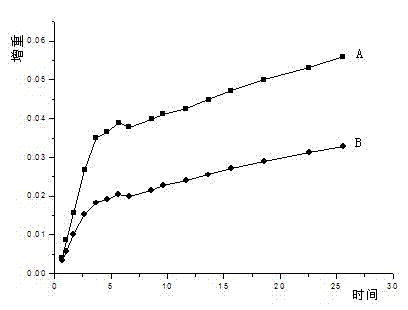

Image

Examples

Embodiment 1

[0016] The invention discloses a preparation method of a lead strip for storage battery polar plates. The lead alloy used to prepare the lead strip for battery pole plates is melted, continuously cast and rolled, and the finished product thickness of the lead strip for battery pole plates is 0.6-0.9 mm.

[0017] In the present embodiment, the rolling reduction rate of the finished rolling pass of the lead strip used for the storage battery pole plate is 35 ~ 40%, and the rolling reduction rate of the finished product rolling pass of the lead strip used for the storage battery pole plate is 22%. ~25%.

[0018] In this embodiment, a heat treatment is carried out before the finished rolling pass of the lead strip for the battery pole plate and after the finished rolling pass of the lead strip for the battery pole plate: before the finished rolling pass of the lead strip for the battery pole plate The temperature of the heat treatment is 270~280℃, and the temperature is kept for ...

Embodiment 2

[0021] The invention discloses a preparation method of a lead strip for storage battery polar plates. The lead alloy used to prepare the lead strip for battery pole plates is melted, continuously cast and rolled, and the finished product thickness of the lead strip for battery pole plates is 0.4-0.6 mm.

[0022] In the present embodiment, the rolling reduction rate of the finished product rolling pass of the battery pole plate lead strip is 30 ~ 35%, and the rolling reduction rate of the finished product rolling pass of the battery pole plate lead strip is 24%. ~30%.

[0023] In this embodiment, a heat treatment is carried out before the finished rolling pass of the lead strip for the battery pole plate and after the finished rolling pass of the lead strip for the battery pole plate: before the finished rolling pass of the lead strip for the battery pole plate The temperature of the heat treatment is 260~270°C, and the temperature is kept for 100~200 seconds. The temperature ...

Embodiment 3

[0026] The invention discloses a preparation method of a lead strip for storage battery polar plates. The lead alloy used to prepare the lead strip for battery pole plates is melted, continuously cast and rolled, and the finished product thickness of the lead strip for battery pole plates is 0.9-1.2 mm.

[0027] In the present embodiment, the rolling reduction rate of the finished rolling pass of the lead strip used for the battery pole plate is 40~44%, and the rolling reduction rate of the finished product rolling pass of the lead strip used for the battery pole plate is 22%. ~26%.

[0028] In this embodiment, a heat treatment is carried out before the finished rolling pass of the lead strip for the battery pole plate and after the finished rolling pass of the lead strip for the battery pole plate: before the finished rolling pass of the lead strip for the battery pole plate The temperature of the heat treatment is 280~290°C, and the temperature is kept for 300~365 seconds. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com