Solar cell and preparation method thereof and method for improving transmission characteristic of perovskite layer

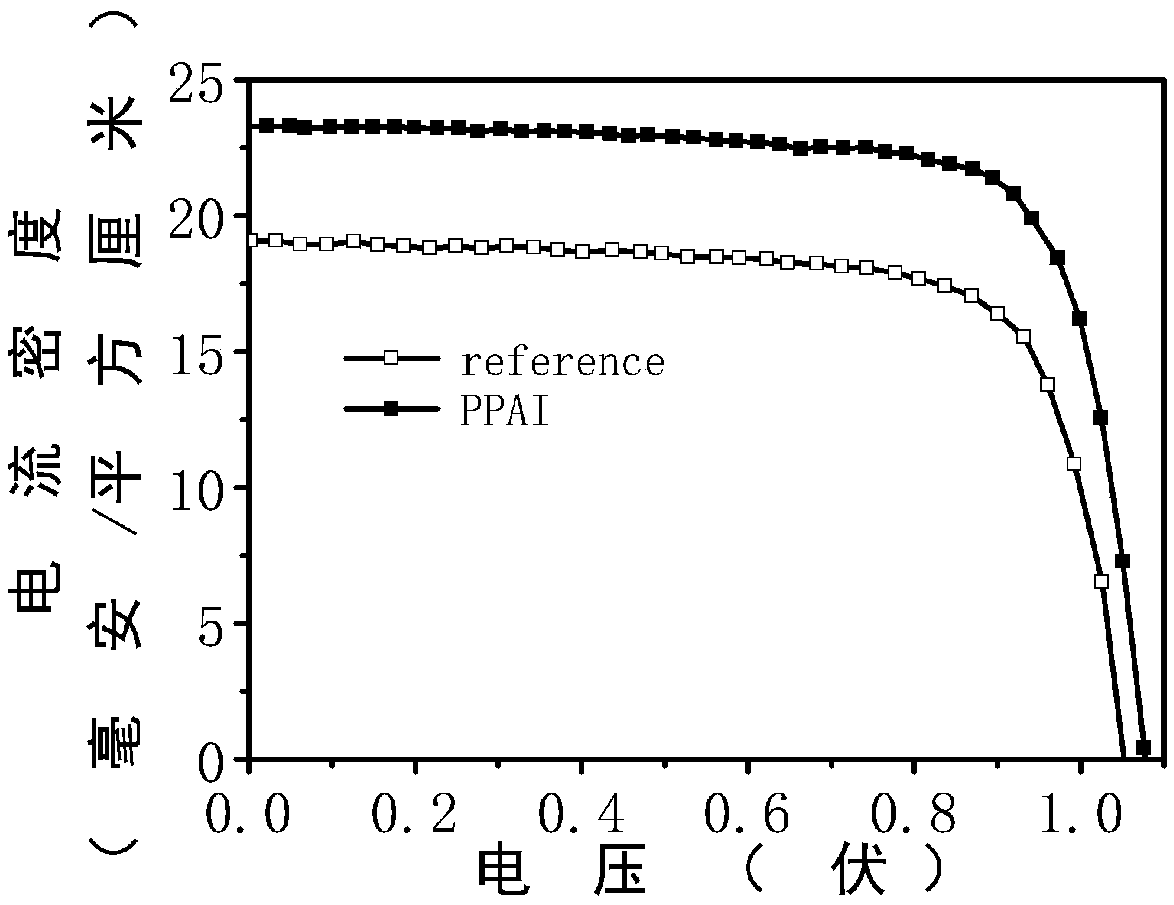

A technology for solar cells and transmission characteristics, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that restrict the development of the efficiency and stability of perovskite solar cells, the carrier coincides seriously, and has not been studied too much , to achieve the effects of improving the light-absorbing layer transmission, reducing film defects, and improving device conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] (2) Preparation of the hole transport layer 3: the dried and treated substrate was treated with oxygen plasma for 15 minutes, and then the hole transport layer was spin-coated on the substrate, preferably poly(3,4-ethylenedioxythiophene) - Polystyrene sulfonic acid (referred to as PEDOT:PSS). The mass fraction of PEDOT:PSS solution is 10%, and the solution is spin-coated with a homogenizer, the rotating speed is selected at 1500rpm, and the homogenization time is 60s. The drying treatment temperature of the obtained hole transport layer film is 150 ° C, and the drying time is 0.5 hour. The thickness is 30nm.

[0064] (3) Preparation of the perovskite layer 4: the perovskite layer 4 was prepared on the hole transport layer 3, and the perovskite layer was prepared by a one-step spin-coating anti-solvent method. Among them, the lead halide selects lead iodide (referred to as PbI 2 ), tin iodide (referred to as SnI 2 ); the ligand selects methylamine iodide (abbreviated ...

Embodiment 1

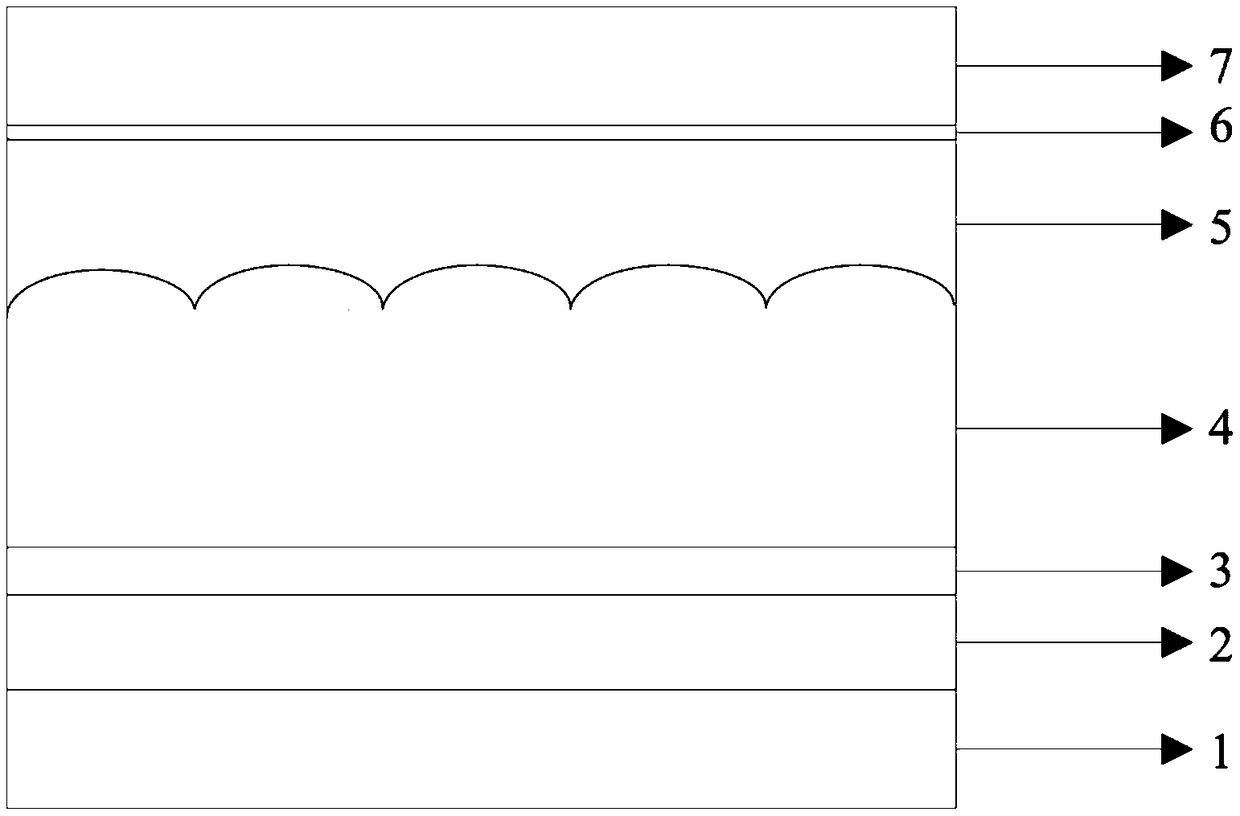

[0070] see figure 1 , the perovskite solar cell device according to the first embodiment of the present invention has the following structure:

[0071] Glass substrate / ITO(100nm) / PEDOT:PSS(30nm) / CH 3 NH 3 PB 3 (400nm) / C60(30nm) / BCP(5nm) / Ag(100nm)

[0072] (1) Cleaning of glass substrates pre-engraved with ITO: Utilize ethanol, acetone ultrasonic and deionized water ultrasonic methods to clean the transparent conductive substrate 1 (ITO glass), and place it under an infrared lamp to dry after cleaning. Wherein the ITO film on the transparent conductive substrate 1 is used as the anode layer 2 of the device, the square resistance of the ITO film is 10-20Ω, and the film thickness is 100-120nm;

[0073] (2) Preparation of the hole transport layer: Treat the dried substrate with oxygen plasma for 15 minutes, then place it on the KW-4A homogenizer, spin-coat the prepared PEDOT:PSS solution by static batching For film formation, the speed of the homogenizer is 1500rpm, the homog...

Embodiment 2

[0080] see figure 1 , the perovskite solar cell device according to the second embodiment of the present invention has the following structure:

[0081] Glass (plastic) substrate / ITO(100nm) / PEDOT:PSS(30nm) / (NH 2 ) 2 CHSnI 3 (200nm) / C60(30nm) / BCP(5nm) / Ag(150nm)

[0082] (1) Cleaning of glass substrates pre-engraved with ITO: Utilize ethanol, acetone ultrasonic and deionized water ultrasonic methods to clean the transparent conductive substrate 1 (ITO glass), and place it under an infrared lamp to dry after cleaning. Wherein the ITO film on the transparent conductive substrate 1 is used as the anode layer 2 of the device, the square resistance of the ITO film is 10-20Ω, and the film thickness is 100-120nm;

[0083] (2) Preparation of the hole transport layer: Treat the dried substrate with oxygen plasma for 15 minutes, then place it on the KW-4A homogenizer, spin-coat the prepared PEDOT:PSS solution by static batching For film formation, the speed of the homogenizer is 1500rp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com