Method for reducing phase change temperature of vanadium dioxide film

A vanadium dioxide, phase transition temperature technology, applied in chemical instruments and methods, heat exchange materials, coatings, etc., can solve the problem of high phase transition temperature, achieve lower phase transition temperature, good optical properties, and excellent optical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

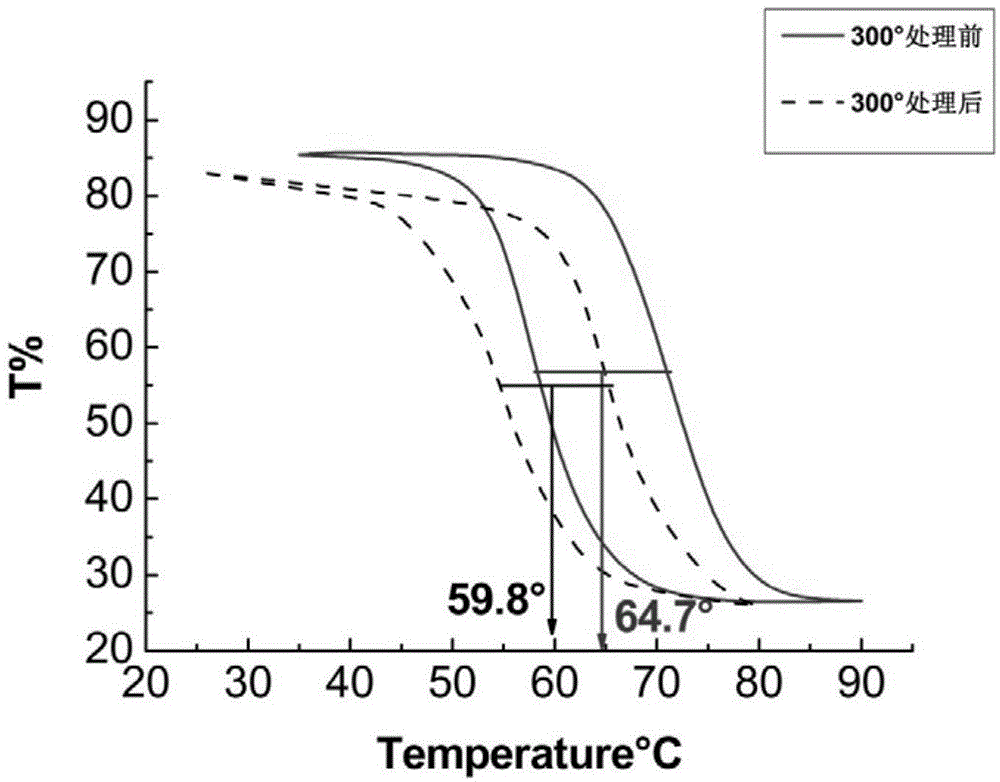

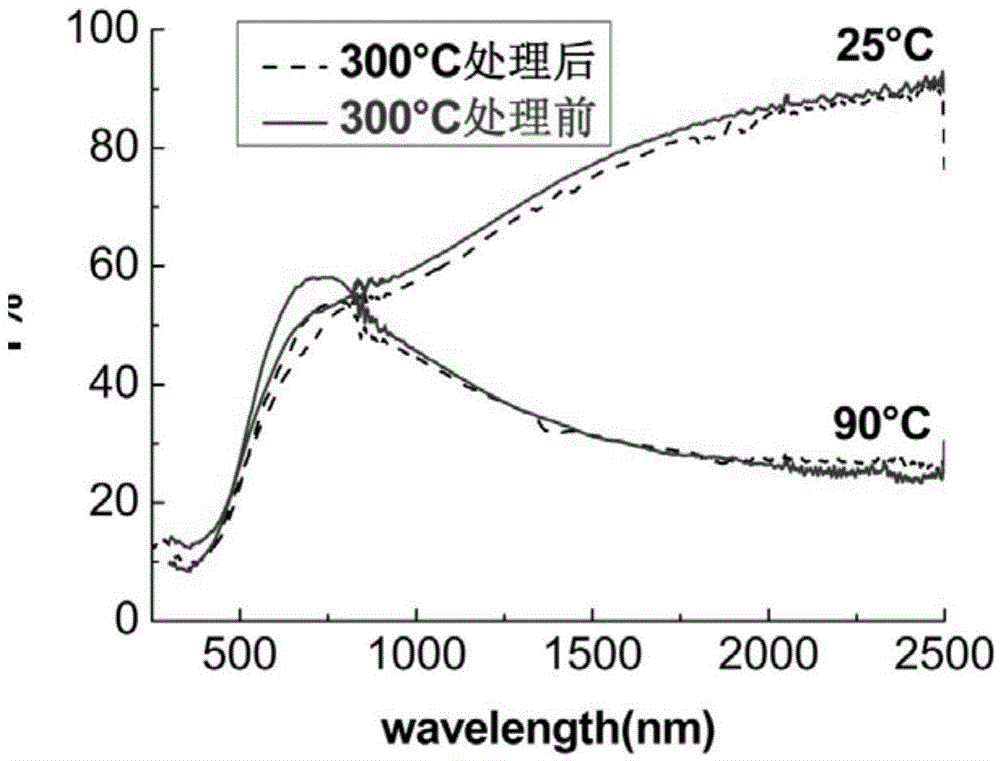

[0035] Take an undoped M-phase vanadium dioxide thin film prepared by an inorganic sol-gel method and measure the thermal hysteresis loop of the film at 2000 nm. The phase transition temperature of the film is measured to be 64.7°C, and the thermal hysteresis loop width is 13°C. Such as figure 1 The solid line shown is the thermal hysteresis loop measured at 2000 nm for the vanadium dioxide thin film prepared in advance. figure 2 The solid line shown in the figure is the transmission curve of the sample measured under the temperature conditions of 25°C and 90°C.

[0036] The sample is placed in a tube-type retreat furnace, evacuated to a vacuum degree of 2000 Pa, and the vacuum pump is continuously turned on to keep the vacuum degree unchanged.

[0037] The heating rate of the tubular annealing furnace is set to 5°C / min, and the temperature is raised to 300°C and kept for 3 hours. Then cool down with the furnace.

[0038] By measuring the thermal hysteresis loop of the undoped vana...

Embodiment 2

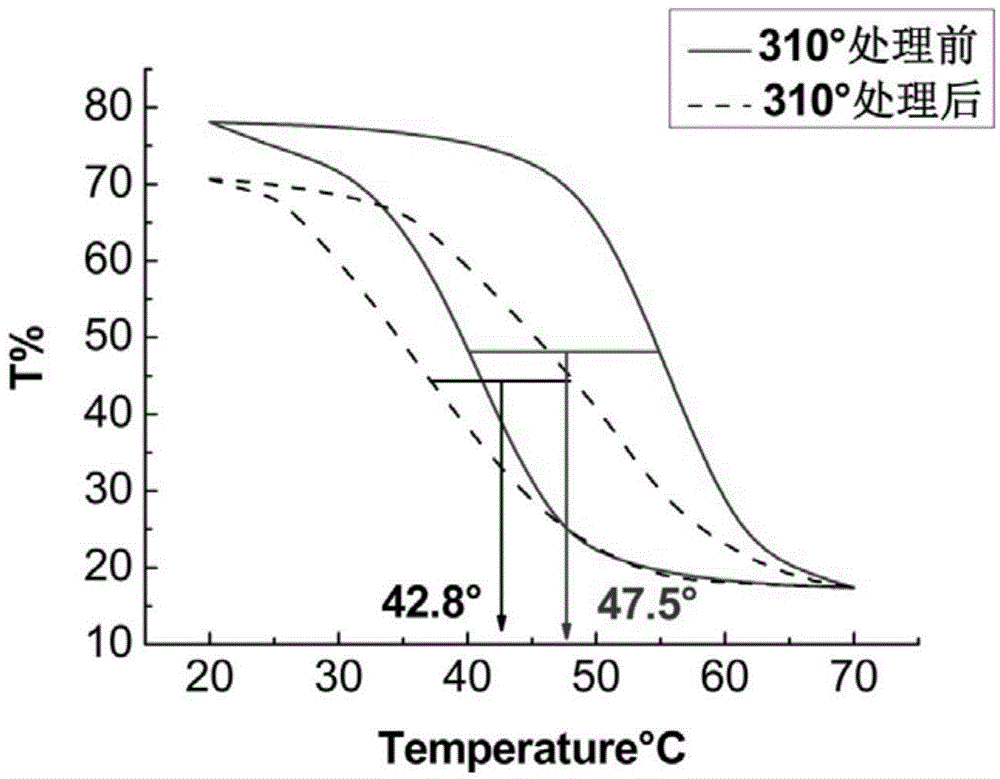

[0040] Take the tungsten-doped (1%) M phase vanadium dioxide thin film prepared by the inorganic sol-gel method, and measure the thermal hysteresis loop of the thin film at 2000nm (such as image 3 As shown by the solid line) and the transmission curve (as Figure 4 The solid line shown), the phase transition temperature of the film is 47.5°C, and the width of the thermal hysteresis loop is 22°C.

[0041] The operation steps are the same as those of the embodiment 1, and the process conditions of step 2) are: evacuating to a vacuum degree of 2000 Pa, and then passing Ar to normal pressure to maintain a relative vacuum. The process conditions of step 3) are that the heating rate is 5° C. / min, the temperature is increased to 310° C. and the temperature is kept for 3 hours, and the temperature is naturally cooled in an Ar atmosphere furnace after the temperature is completed.

[0042] By measuring the thermal hysteresis loop of the undoped vanadium dioxide film at 2000 nm, the phase tr...

Embodiment 3

[0044] Take the undoped M-phase vanadium dioxide thin film prepared by magnetron sputtering method, and measure the thermal hysteresis loop of the thin film at 2000nm (such as Figure 5 The solid line shown), the phase transition temperature of the film is 49°C, and the width of the thermal hysteresis loop is 23°C.

[0045] The operation steps are the same as those in Example 1, and the process conditions of step 2) are as follows: evacuating to a vacuum degree of 1000 Pa, and continuously turning on the vacuum pump to maintain a high vacuum. The process condition of step 3) is that the heating rate is 10°C / min, the temperature is increased to 320°C and the temperature is maintained for 2 hours, and the temperature is naturally cooled in the furnace after the temperature is completed.

[0046] By measuring the thermal hysteresis loop of the undoped vanadium dioxide film at 2000 nm, the phase transition temperature of the film is measured to be 43°C, and the width of the thermal hys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com