Spray coating solution, perovskite layer, preparation method of perovskite layer and perovskite cell

A technology of perovskite and spraying liquid, which is applied in coatings, devices and circuits for coating liquid on the surface, etc., can solve problems such as poor quality of perovskite layers, and achieve the advantages of less film holes, lower production costs, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

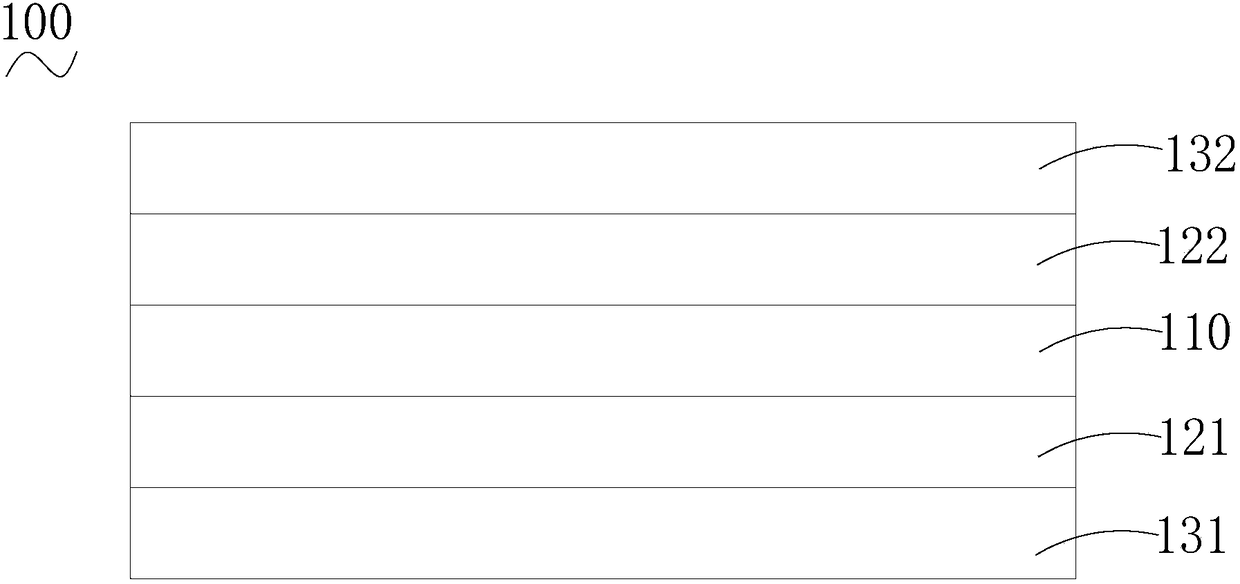

[0040] The invention also provides a preparation method of the perovskite layer.

[0041] A method for preparing a perovskite layer, comprising the steps of:

[0042] The spray liquid provided by the invention is ultrasonically sprayed on the substrate, and then annealed to obtain a perovskite layer.

[0043] Among them, ultrasonic spraying is to atomize the spraying liquid flowing through the ultrasonic transducer through the ultrasonic transducer to produce fine droplets of micron to nanometer scale; and then compress the gas to further make the droplets smaller and homogenized, and at the same time Guide the running direction of the mist particles and increase the running power of the atomized particles.

[0044] Preferably, during ultrasonic spraying, the ultrasonic frequency is 90KHz, the spraying flow rate is 0.5mL / min-1mL / min, the carrier gas is nitrogen, the air pressure is 0.02MPa-0.1MPa, and the atomization current is 0.07A. This could further improve the quality o...

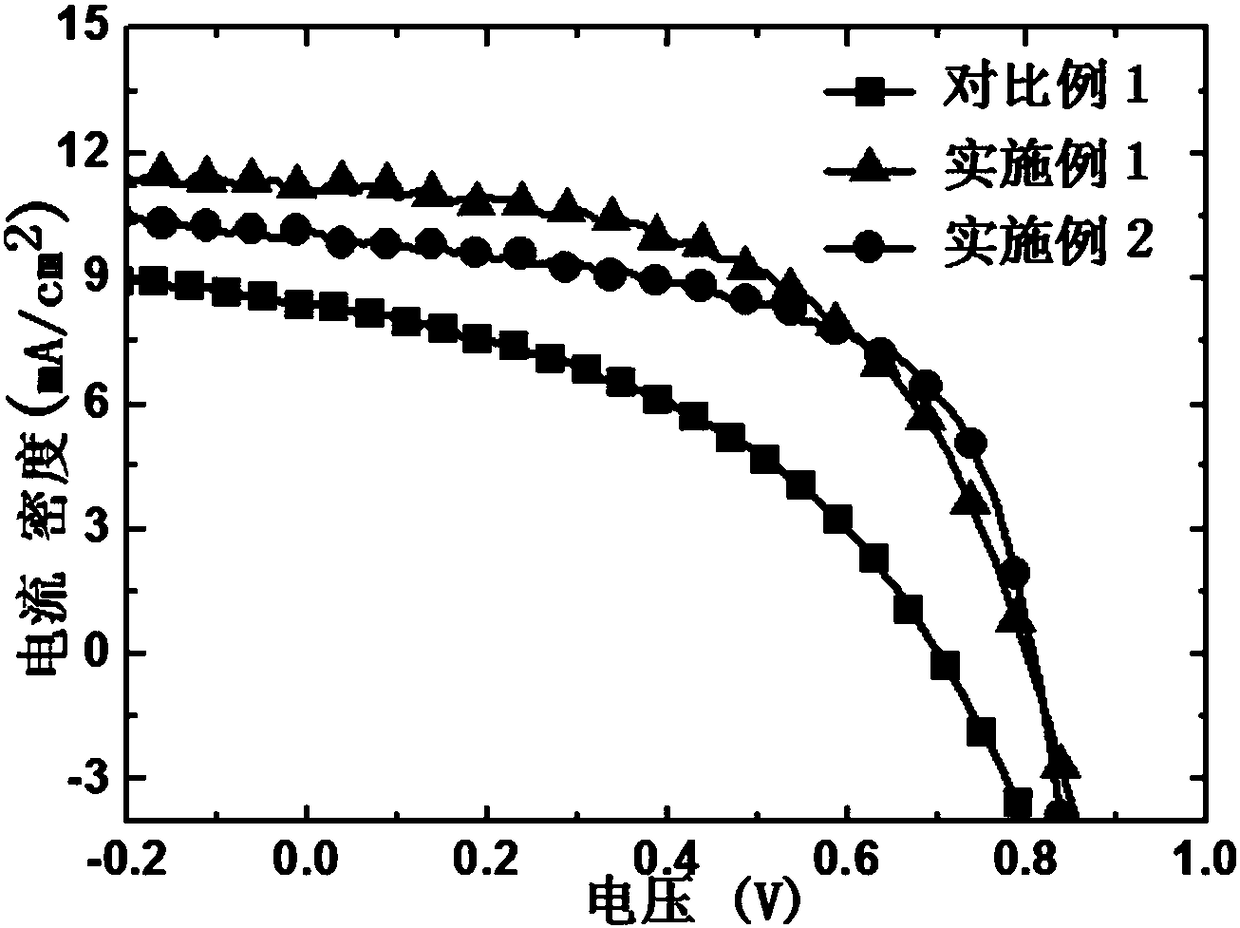

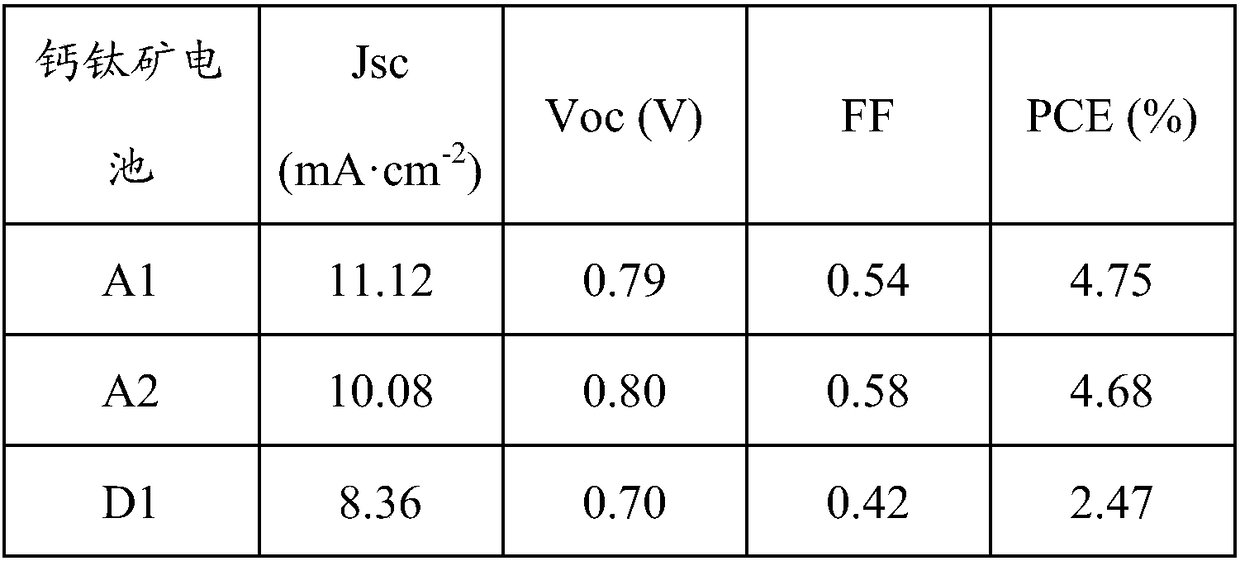

Embodiment 1

[0081] 1. Clean the transparent conductive substrate

[0082] The FTO conductive glass was ultrasonically cleaned in ethanol and deionized water for 15 min respectively, and then dried with nitrogen.

[0083] 2. Preparation of n-type conductive layer

[0084] Prepare 25mg / mL of SnCl 2 "5H 2 O in ethanol solution, and 5 mg / mL lithium bistrifluoromethanesulfonimide (Li-TFSI) in ethanol solution was added, and ultrasonically dissolved.

[0085] After the ultrasonic solution was filtered with a 0.45 μm filter head, it was coated on the FTO conductive glass by spin coating at a speed of 3000 rpm / s. After spinning for 20 s, it was placed on a heating plate at 200 ° C for 1 h.

[0086] 3. Preparation of perovskite layer

[0087] In a beaker, add 0.794g of methylamine iodine (MAI), 2.454g of PbI 2 , and then add 80mL of acetonitrile (CAN), 20mL of 33wt% methylamine in ethanol, ultrasonically dissolve, and prepare a 0.05M perovskite precursor solution. The color of the solution is...

Embodiment 2

[0096]Basically the same as Example 1, the difference is the preparation of the perovskite layer. details as follows:

[0097] In a beaker, add 0.794g of methylamine iodine (MAI), 2.454g of PbI 2 , and then add 80mL of acetonitrile (CAN), 20mL of 33wt% methylamine in ethanol, ultrasonically dissolve, and prepare a 0.05M perovskite precursor solution. The color of the solution is light yellow; the spray solution is obtained.

[0098] Raise the temperature of the heating substrate to 45°C, place the substrate obtained in step 2 on the heating substrate for heating, and ultrasonically spray the spraying liquid on the substrate at 45°C, the carrier gas is nitrogen, the air pressure is 0.02MPa, and the atomization current is 0.07A , the ultrasonic frequency of the ultrasonic spraying equipment is 90KHz, the spraying flow rate is 0.5mL / min, the spraying time is 3min, and the color of the matrix completely changes from yellow to black after 1min of spraying. The substrate was heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com