Phosphorus-containing interstitial-free cold-rolled galvanized steel sheet, and manufacturing method thereof

An interstitial atom-free, galvanized steel sheet technology, applied in the field of iron-based alloys, can solve the problems of high manufacturing cost and poor manufacturability, and achieve the effects of low manufacturing cost, good manufacturability and high yield-to-strength ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

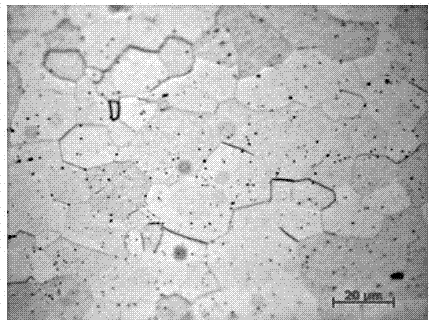

Image

Examples

Embodiment Construction

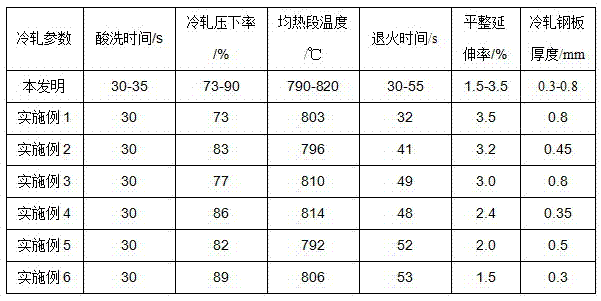

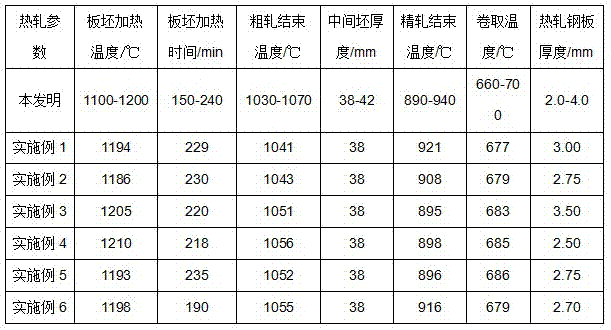

[0050] The present invention will be further described below in conjunction with Embodiments 1-6.

[0051] Table 1 shows the chemical composition (by weight percentage) of the steel of the embodiment of the present invention, and the balance is Fe and unavoidable impurities.

[0052] Table 1 Chemical composition of the steel of the embodiment of the present invention, unit: weight percent.

[0053]

[0054] According to the requirements of the material composition design of the present invention, the molten steel meeting the required chemical composition is obtained by using converter melting, and the molten steel is subjected to vacuum degassing treatment in the RH furnace and then continuously cast to obtain a continuous casting slab with a thickness of 210-230mm and a width of 800-1300mm , the length is 5000~10000mm, and the RH pure degassing time is more than 10 minutes.

[0055] The cut-to-length slab produced by steelmaking is sent to the heating furnace for reheatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com