Rigid mineral insulated fireproof cable

A mineral insulated, fire-resistant cable technology, applied in the direction of insulated cables, insulated conductors, flexible cables, etc., can solve the problems of low impact protection level, lack of high temperature protection, and long-term fire resistance, etc., and reach the temperature resistance level High, improved heat dissipation, stable strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

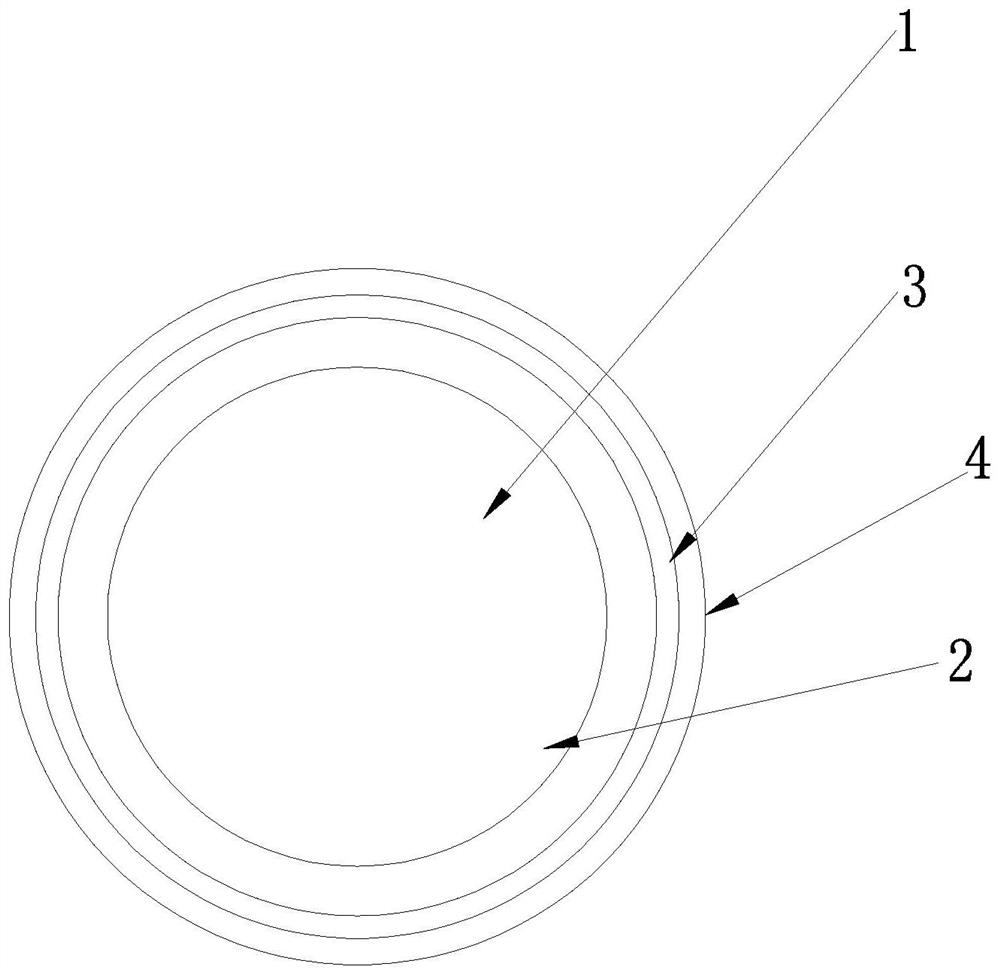

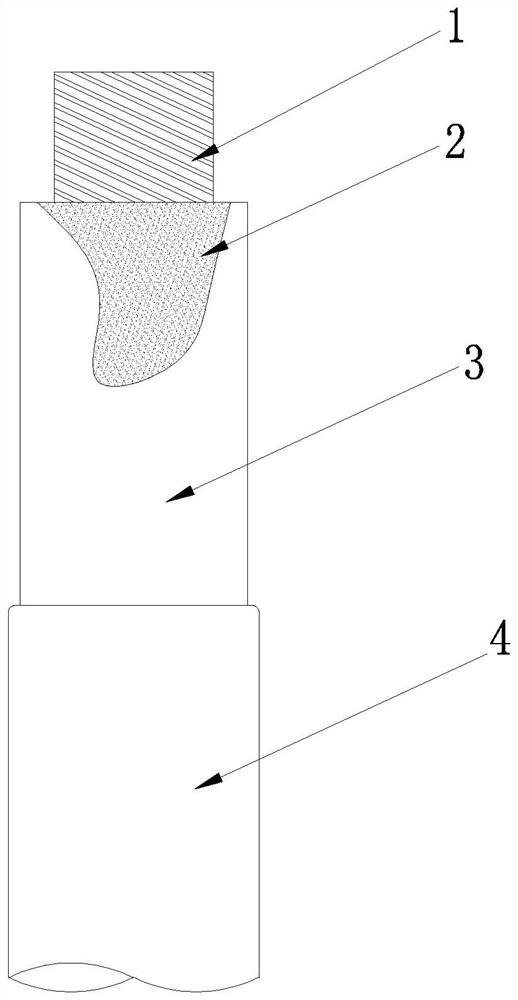

[0038] Such as Figure 1-2 As shown, a mineral insulation fire protection provided in this embodiment includes a first conductor 1, wherein the number of the first conductor 1 is 1 to 5 strands, and is a solid structure. In this embodiment, the number of the first conductor 1 is 1 strand, the first conductor 1 is copper; the conductor surface of the first conductor 1 is filled with high-purity magnesia insulating layer 2, and the surface of the high-purity magnesia insulating layer is welded and rolled and drawn copper sheath 3, welded and rolled and drawn copper sheath The surface of the sleeve 3 is extruded with a halogen-free low-smoke flame-retardant polyolefin sheath 4 as required.

Embodiment 2

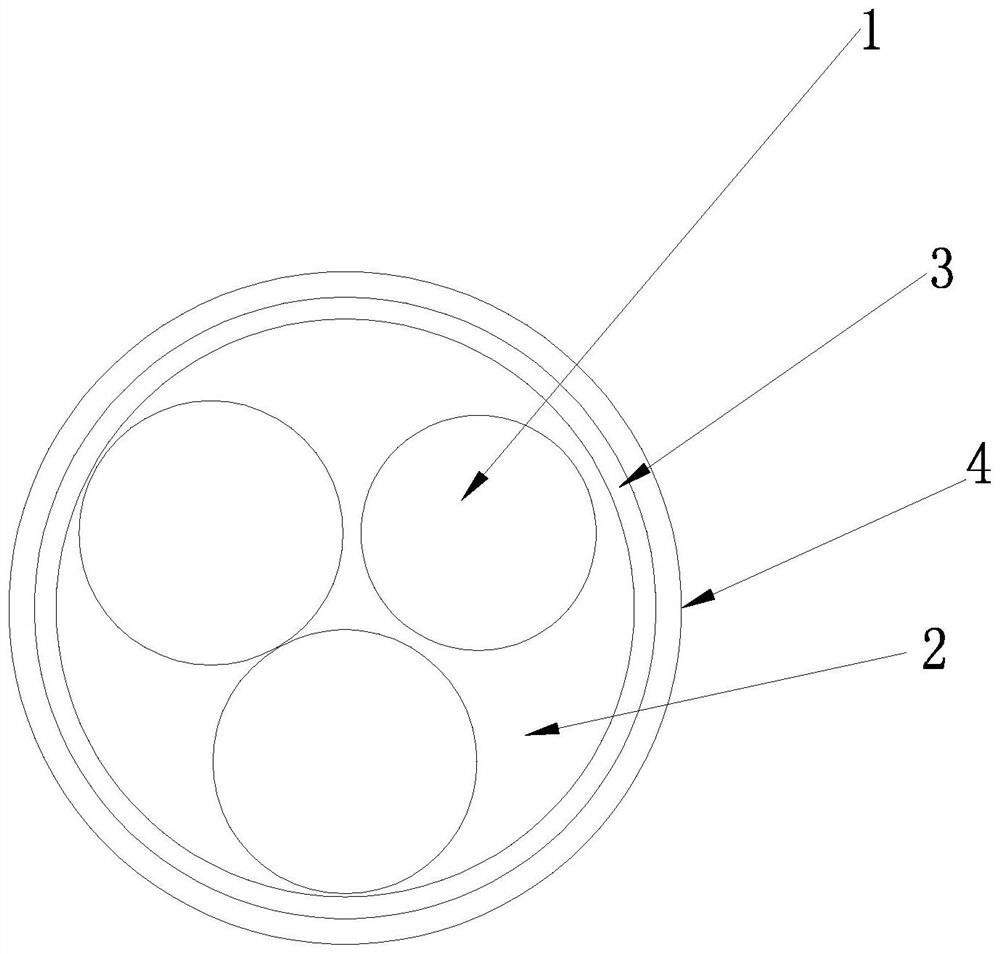

[0040] Such as Figure 3-4 As shown, a rigid mineral insulated fireproof cable provided in this embodiment includes a first conductor 1, wherein the number of the first conductor 1 is 1 to 5 strands, and is a solid structure. In this embodiment, the first conductor 1 The quantity is 3 strands, the first conductor 1 is copper; the conductor surface of the first conductor 1 is filled with high-purity magnesia insulating layer 2, and the surface of the high-purity magnesia insulating layer is welded, rolled and drawn copper sheath 3, welded, rolled and drawn The surface of the copper sheath 3 is extruded with a halogen-free low-smoke flame-retardant polyolefin sheath 4 as required.

[0041] The cable of the present invention has high temperature resistance and long service life, can be applied to various natural high temperature environments, has high reliability, is less affected by climate conditions and surrounding environments, and has stable transmission performance; it is g...

Embodiment 3

[0067] Embodiment 3, the correction factor table when the ambient air temperature is not equal to 30°C (for the ampacity of cables laid in the air)

[0068] ambient temperature PVC outer sheath and inaccessible bare sheath Bare sheath not allowed to touch 25 1.07 1.04 30 1.00 1.00 35 0.93 0.96 40 0.85 0.92 45 0.77 0.88 50 0.67 0.84 55 0.57 0.80 60 0.45 0.75 65 —— 0.70 70 —— 0.65 75 —— 0.60 80 —— 0.54

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com