Heat treatment method after repair of blades of aero-engine compressor integral blisks

A technology of aero-engine and heat treatment method, which is applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of not deteriorating the mechanical properties of GH4169G alloy matrix, and achieve the effects of not degrading mechanical properties, improving mechanical properties, and shortening production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

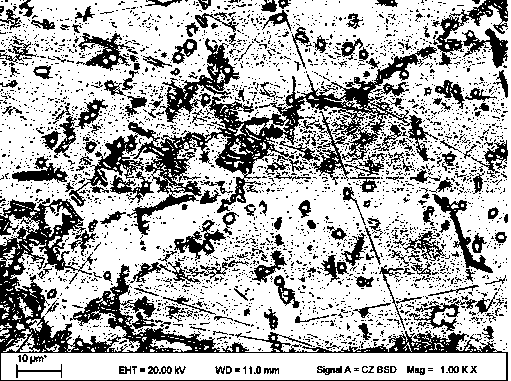

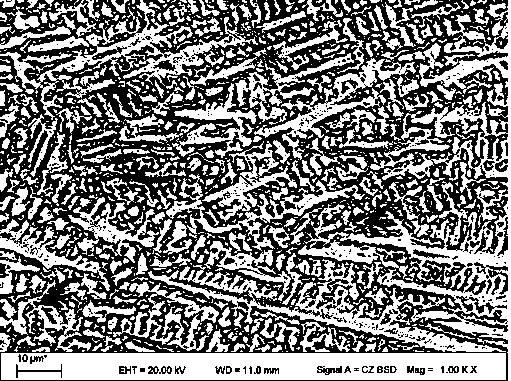

[0015] The compressor of a certain type of aero-engine adopts an integral blisk structure, and its material is GH4169G superalloy. Usually, GH4169G powder with the same chemical composition as the base material is used as the repair raw material, and the laser additive technology is used for repair. After repairing, adopt the heat treatment system of the present invention to process. at least 10 ~2 Under the condition of vacuum degree of Pa, put the repaired parts into the vacuum furnace, heat up to 760°C at 12°C / min, cool to 620°C at 50°C / h after holding for 2.0 hours, and cool to room temperature in air after holding for 4.0 hours. The performance test was carried out with furnace samples (including unrepaired substrates and semi-additive repaired plate samples). The hardness test shows that the matrix is 47.7-45.6HRC, and the additive repair area is 43.5-44.2HRC. The scanning electron microscope morphology of the substrate after heat treatment is as follows: figure 1 S...

Embodiment 2

[0028] The compressor of a certain type of aero-engine adopts an integral blisk structure, and its material is GH4169G superalloy. Usually, GH4169G powder with the same chemical composition as the base material is used as the repair raw material, and the laser additive technology is used for repair. After repairing, adopt the heat treatment system of the present invention to process. at least 10 ~2 Under the condition of vacuum degree of Pa, put the repaired parts into the vacuum furnace, heat up to 750°C at 10°C / min, cool to 610°C at 55°C / h after holding for 2.1 hours, and cool to room temperature in air after holding for 4.1 hours. The performance test was carried out with furnace samples (including unrepaired substrates and semi-additive repaired plate samples). The hardness test shows that the matrix is 47.4-45.6HRC, and the additive repair area is 43.5-44.1HRC.

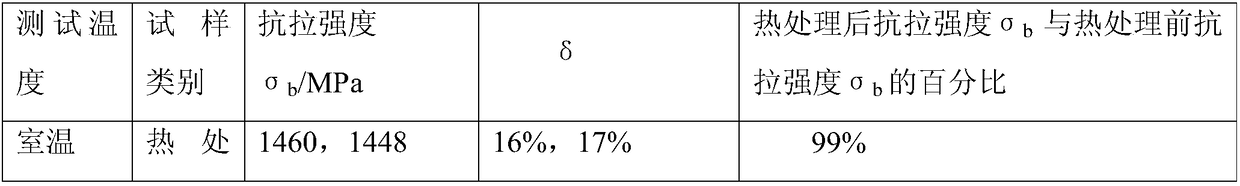

[0029] The mechanical performance test results are shown in Table 4, Table 5, Table 6 and Table 7. The me...

Embodiment 3

[0040] The compressor of a certain type of aero-engine adopts an integral blisk structure, and its material is GH4169G superalloy. Usually, GH4169G powder with the same chemical composition as the base material is used as the repair raw material, and the laser additive technology is used for repair. After repairing, adopt the heat treatment system of the present invention to process. at least 10 ~2 Under the condition of Pa vacuum, put the repaired parts into the vacuum furnace, heat up to 770°C at 15°C / min, cool to 630°C at 45°C / h after holding for 1.9 hours, and cool to room temperature in air after holding for 3.9 hours. The performance test was carried out with furnace samples (including unrepaired substrates and semi-additive repaired plate samples). The hardness test shows that the matrix is 47.8-45.7HRC, and the additive repair area is 43.4-44.2HRC.

[0041] The mechanical performance test results are shown in Table 8, Table 9, Table 10 and Table 11. The mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com