Preparation method and device for 110kV-and-above insulating material capable of chemically crosslinking

A technology of chemical cross-linking and insulating materials, which is applied in the field of high-voltage chemical cross-linking materials to achieve the effect of ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

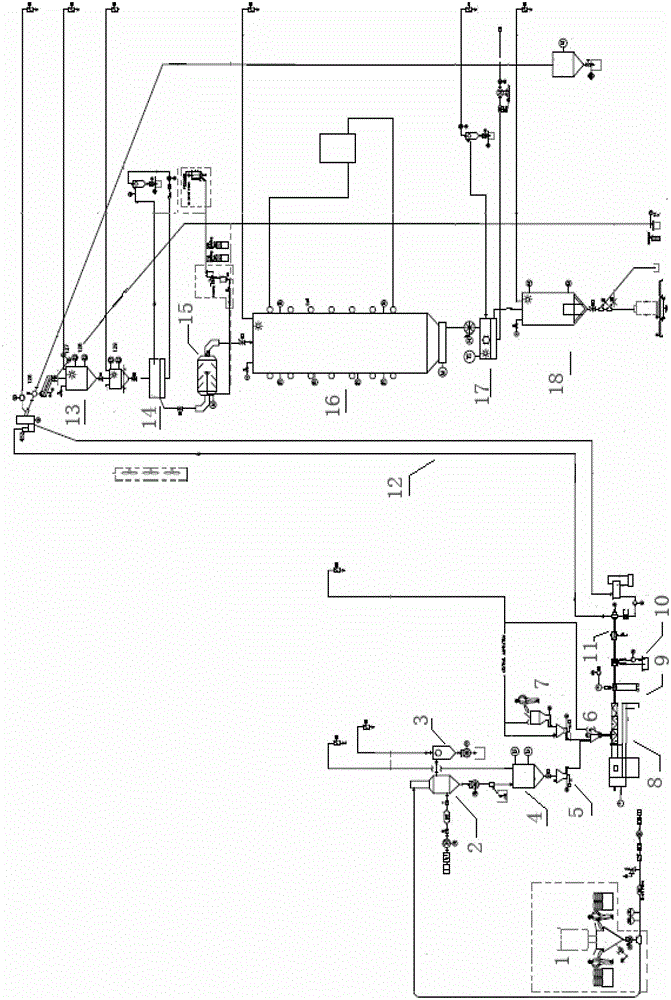

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 , is a structural schematic diagram of the present invention, the raw materials for producing chemical cross-linked materials such as polyethylene resin and cross-linking agent enter the equipment of the present invention through the raw material delivery device 1 at the same time, and are transported to the filter 2 by the delivery pipeline, and the particle size is filtered out. Raw materials that meet the requirements are recovered by the metal separator 21, and raw materials that do not meet the requirements are recovered. The raw materials in the filter 2 are sampled at any time, and the filter 2 is connected to a manual sampler 3 to collect samples of the raw materials and check the purity. Then the raw materials that meet the requirements are passed into the feeding device 4. In the feeding device, the raw material resin and the crosslink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com