Pixel structure, display panel and method for manufacturing optoelectronic device

A manufacturing method and technology of pixel structure, applied in the field of display panel and optoelectronic device manufacturing, pixel structure, can solve the problems of high production cost, complicated steps, inability to effectively increase production capacity, etc., to increase production capacity, shorten process time, capacitance Value boost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

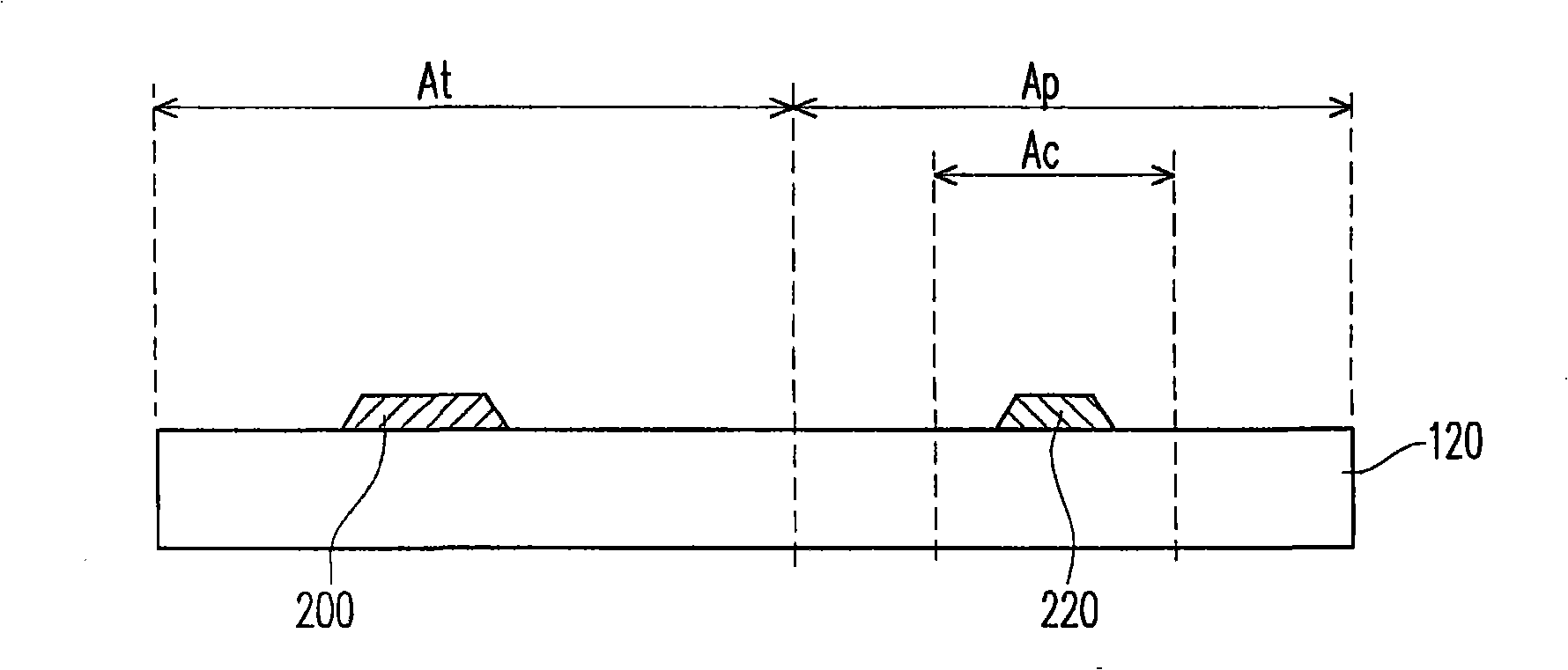

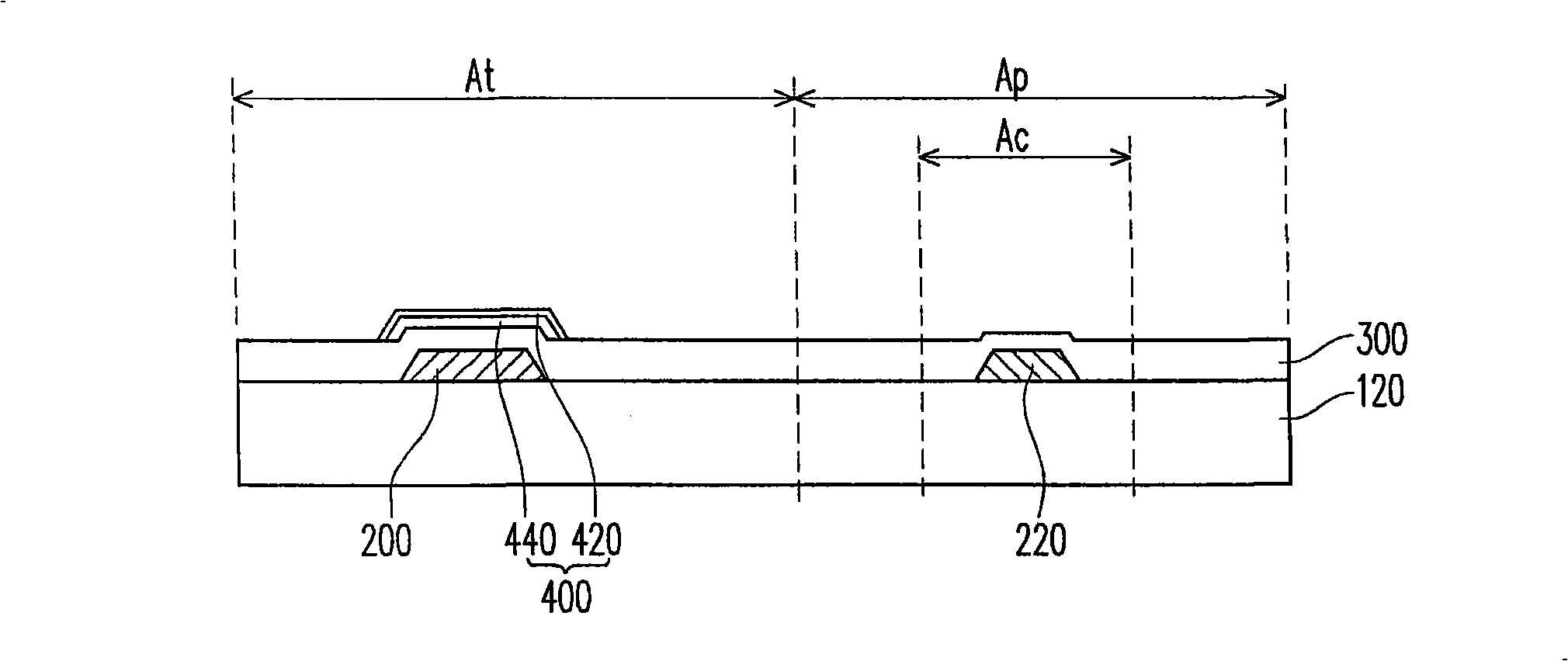

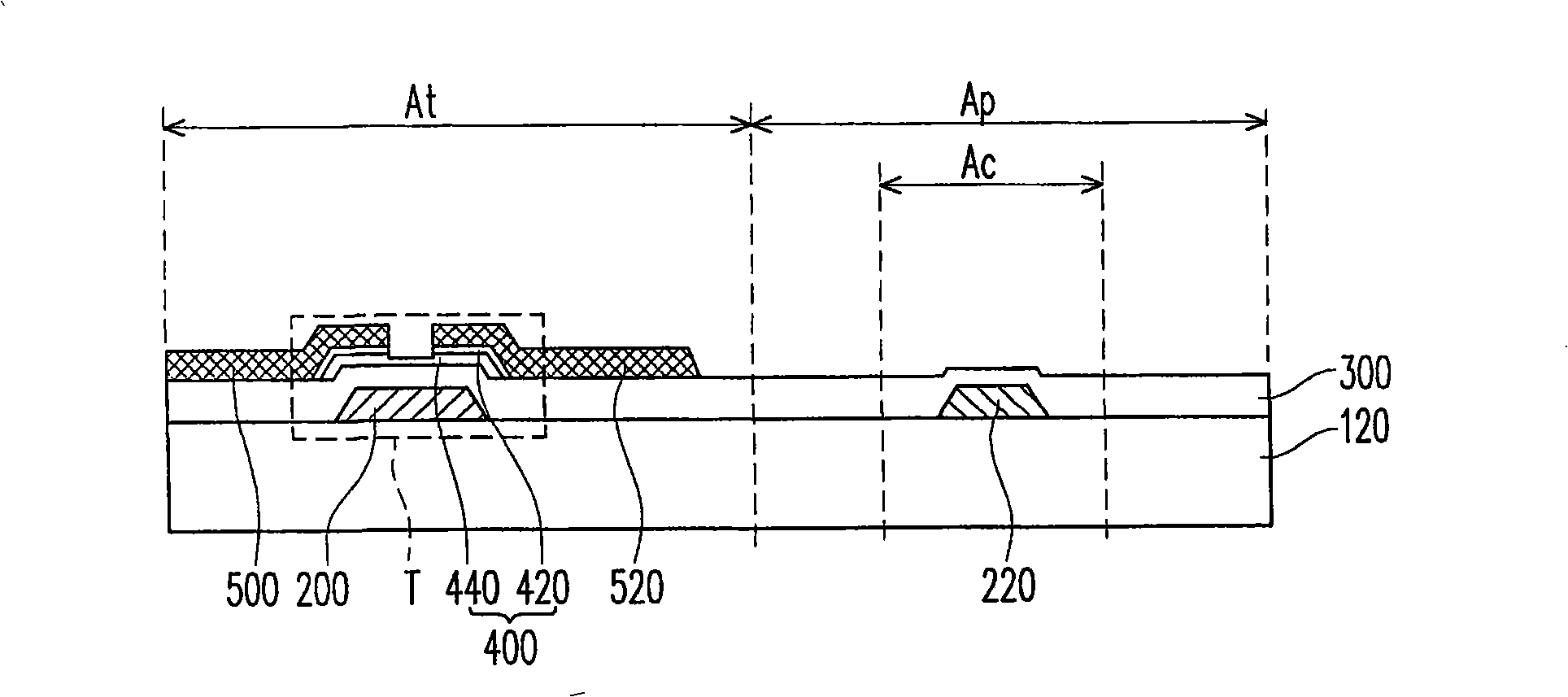

[0064] Figure 1A to Figure 1J is a schematic cross-sectional view of a method for manufacturing a pixel structure according to an embodiment of the present invention, wherein Figure 1A ~ Figure 1J A pixel structure is used as a representative for illustration. First, please refer to Figure 1A , the substrate 120 is provided, and the substrate 120 has a transistor region At, a capacitor region Ac and a pixel region Ap. In the present invention, one of the transistor region At, the capacitor region Ac and the pixel region Ap is illustrated as an example, but not limited thereto. In other embodiments, at least one of the transistor region At, the capacitor region Ac, and the pixel region Ap can be at least one of the above-mentioned ones according to design requirements, such as: different visible regions, increased capacitance, different control capabilities, etc., can be at least more than one. Next, the gate 200 is formed in the transistor region At of the substrate 120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com