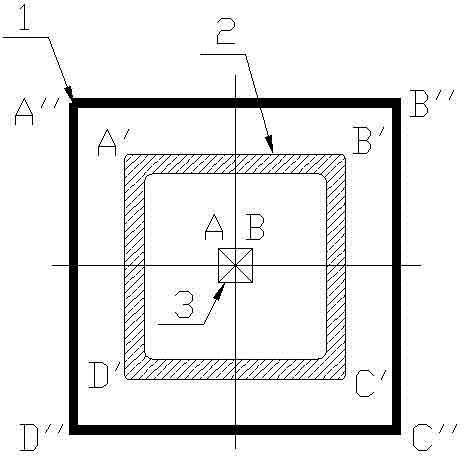

Growth method for preparing square sapphire crystal by Kyropoulos process

A technology of sapphire crystal and growth method, which is applied in the field of growth technology of high-quality square sapphire crystal prepared by Kyropoulos method, which can solve problems such as large crystal stress and difficulty in seeding square sapphire single crystal, achieve less internal defects, and improve crystal utilization rate, the effect of improving the material yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Put the high-purity alumina powder and the square prefabricated block tightly in the crucible, install the seed crystal with the end face in the A direction, and the side faces in the M and C directions on the seed crystal clip, vacuumize and heat up the material. Drop the seed crystal to a position 8mm away from the liquid surface and preheat for 30 minutes. Adjust the temperature of the melt surface to slightly lower than the crystallization temperature of alumina, and gradually reduce the height of the seed crystal to make it contact with the melt surface. At this time, set the automatic rotation parameter to 3rpm to ensure that the growth time of each layer is controlled at After 3 minutes, after lifting 5 layers, set the automatic rotation parameter to 8rpm and enter the necking stage. There are 5 layers in the necking stage, and the growth time of each layer is controlled at 6 minutes. After the seeding is finished, slowly rotate the seed crystal to the position ...

Embodiment 2

[0025] Put the high-purity alumina balls and the round prefabricated block tightly in the crucible, install the seed crystal with the end face in the M direction and the side faces in the A and C directions on the seed crystal clip, vacuumize and heat up the material. Slowly drop the seed crystal at a constant speed until the position 5mm away from the liquid surface is preheated for 20 minutes. Adjust the surface temperature of the melt to make it slightly lower than the melting point of alumina, and gradually reduce the height of the seed crystal to make it contact with the surface of the melt. At this time, set the automatic rotation parameter to 5rpm to ensure that the growth time of each layer is controlled at 5min , after proposing 3 layers, set the automatic rotation parameter to 10rpm and enter the necking stage. There are 3 layers in the necking stage, and the growth time of each layer is controlled at 8 minutes. After the seeding is finished, slowly rotate the seed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com