Sealing agent curing device

A curing device and sealing glue technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as long curing time and product yield drop, and achieve the effects of saving process time, improving product yield, and saving use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

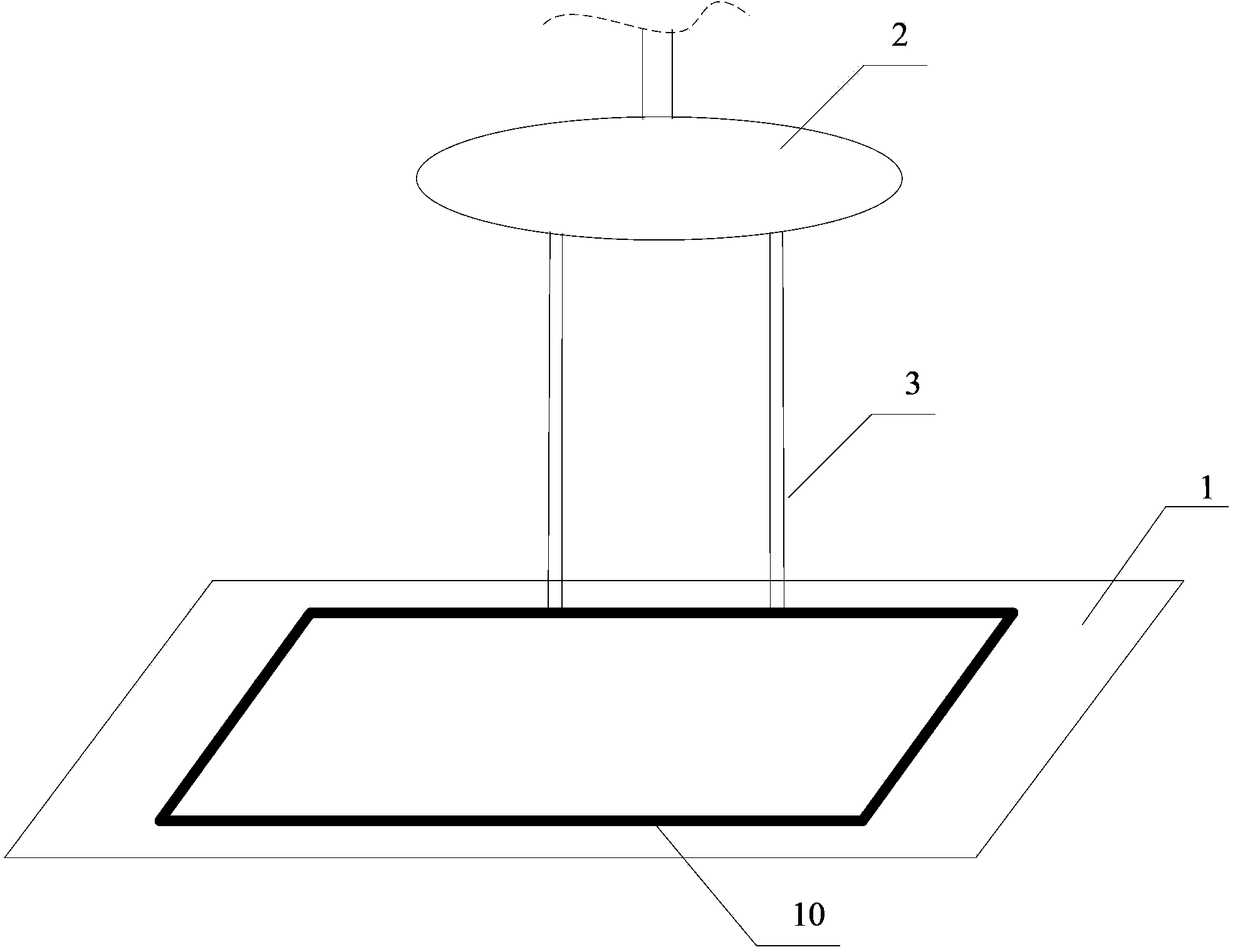

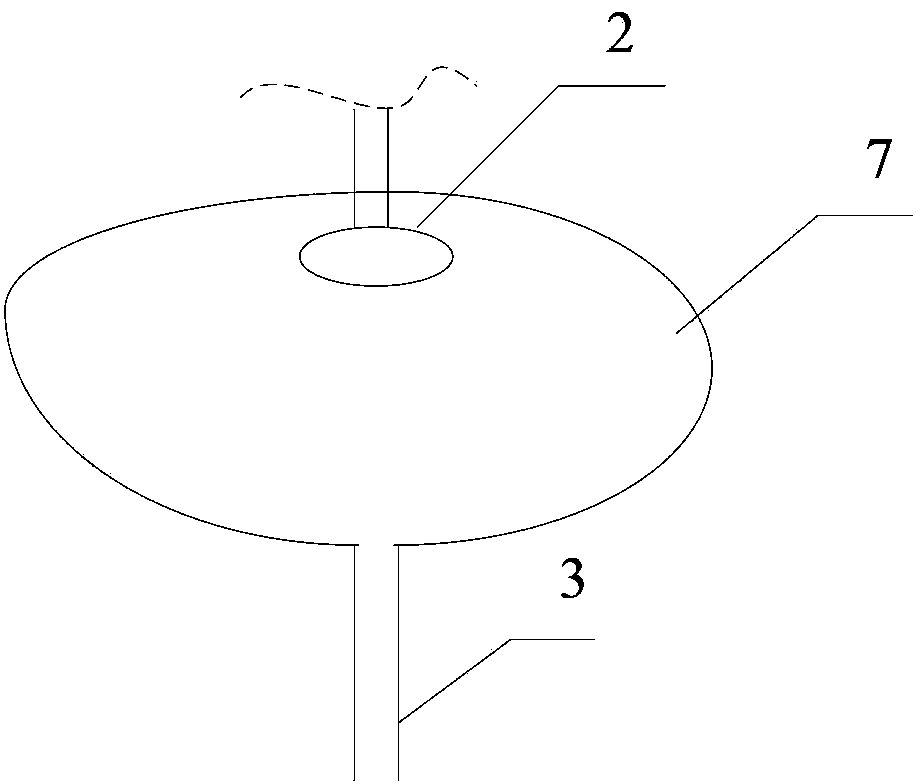

[0027] Embodiment 1 of the present invention provides a frame sealant curing device, the curing device includes a sealed box, an ultraviolet light source 2 arranged in the sealed box, and an optical fiber 3 arranged in the sealed box and connected to the ultraviolet light source, such as figure 1 As shown, among them, figure 1 The sealed box is not indicated in the box.

[0028] Specifically, in the embodiment of the present invention, the optical fiber 3 is used to transmit the ultraviolet light emitted by the ultraviolet light source 2 to the position of the sealant 10 to be cured on the packaging substrate 1 placed in the sealed box. Expose at the position where the sealant 10 to be cured is arranged, and cure the sealant at the position.

[0029] Preferably, in the embodiment of the present invention, a switch component (not shown in the figure), such as a light valve, can be provided between the optical fiber 3 and the ultraviolet light source 2, and whether the light em...

Embodiment 2

[0036] Embodiment 2 of the present invention will describe the frame sealant curing device involved in Embodiment 1 in detail in combination with practical applications, but of course it is not limited thereto.

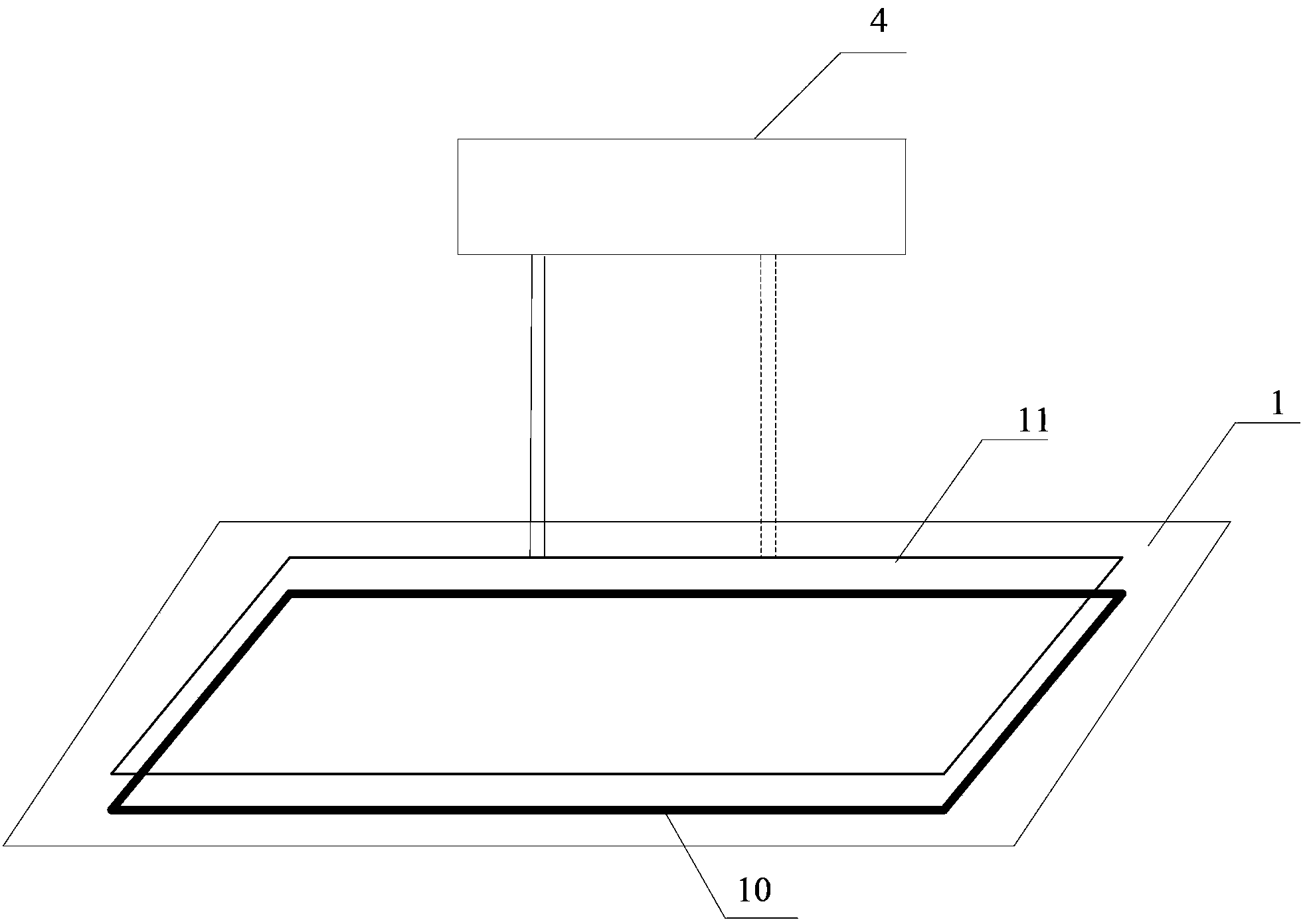

[0037] In the embodiment of the present invention, a transmission part 4 may be provided in the frame sealant curing device involved in the first embodiment, the optical fiber 3 is fixed on the transmission part 4, and the transmission part 4 drives the optical fiber to move on a plane parallel to the packaging substrate.

[0038] Further preferably, in the embodiment of the present invention, the transmission part 4 can be routed according to the position of the sealant to be cured on the packaging substrate 1, so that the trajectory 11 driven by the transmission part 4 to move the optical fiber 3 and the wiring of the sealant to be cured on the packaging substrate Consistent, and finally transmit the ultraviolet light emitted by the ultraviolet light source to the co...

Embodiment 3

[0043] Embodiment 3 of the present invention will describe the frame sealant curing device involved in Embodiment 1 in detail in combination with practical applications, and of course it is not limited thereto.

[0044] Embodiment 3 of the present invention In the frame sealant curing device involved in Embodiment 1, there are several optical fibers 3 connected to the ultraviolet light source 2 , and several optical fibers 3 are arranged on the top of the sealing box 5 .

[0045] Specifically, the arrangement of the optical fibers 3 arranged on the top of the sealed box in the embodiment of the present invention can be flexibly arranged, for example, several optical fibers 3 are evenly arranged on the top of the sealed box 5 at fixed intervals, such as Figure 5 shown.

[0046] Specifically, using Figure 5 In the arrangement shown, when it is necessary to cure the sealant to be cured on the packaging substrate 1, the optical fiber at the position corresponding to the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com