Cutting technique

A technology of cutting process and beam cutting, which is applied in glass cutting devices, manufacturing tools, glass manufacturing equipment, etc., can solve the problems affecting the processing accuracy and yield, and the uneven section of liquid crystal display panel 110, so as to save process time and optimize Effect of cutting cross section and reducing tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

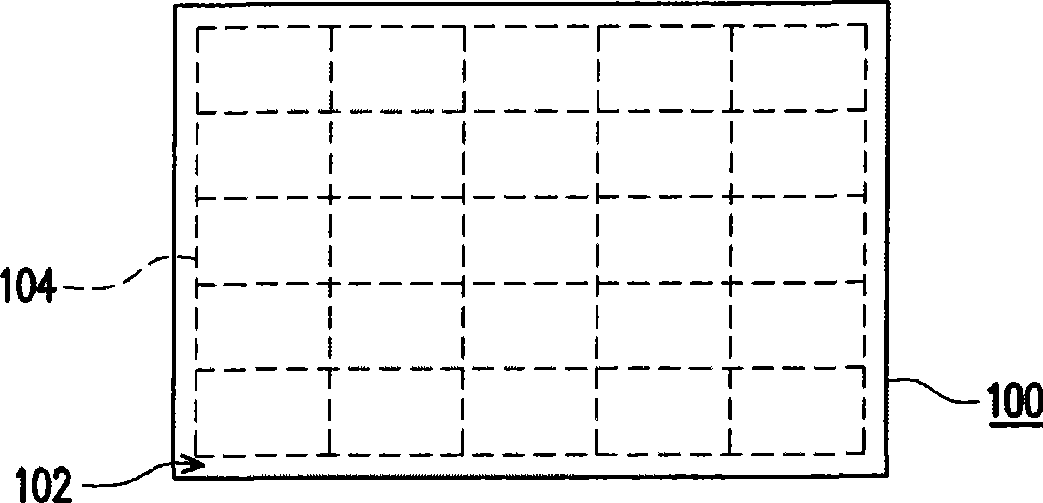

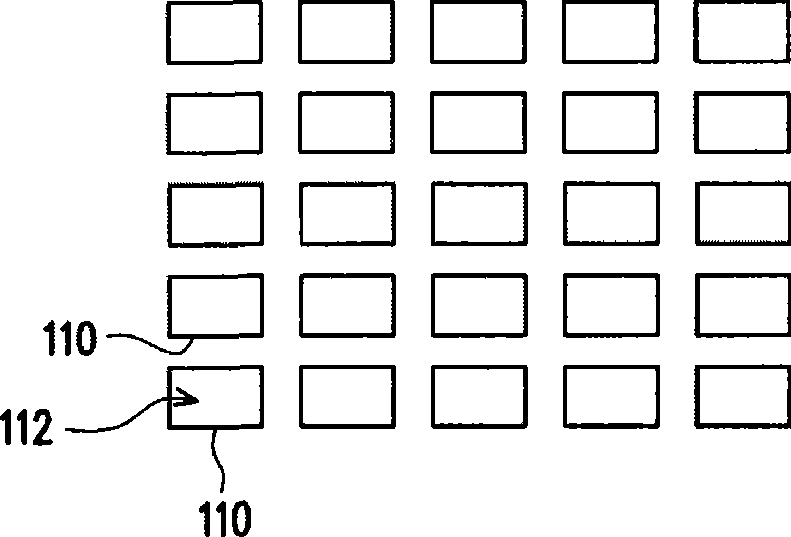

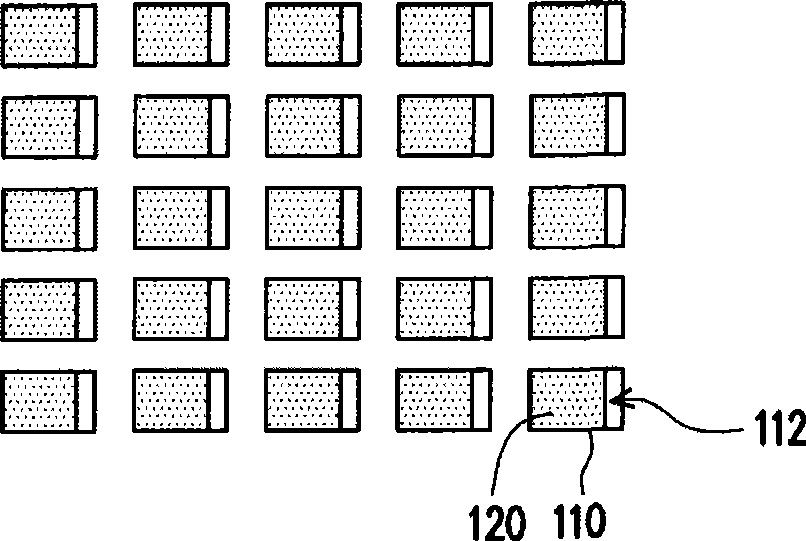

[0035] Figure 2A to Figure 2D It is a schematic flow diagram of a cutting process according to an embodiment of the present invention, wherein Figure 2A and Figure 2D is a schematic top view of the cutting process, and Figure 2B and Figure 2C is a three-dimensional schematic diagram of the cutting process. The cutting process of this embodiment is suitable for cutting a workpiece 200, wherein the workpiece 200 may be a finished product, a semi-finished product or a mother sheet of a liquid crystal display panel. This embodiment uses a glass substrate as an example of the workpiece 200, but is not limited thereto. In this embodiment, the workpiece 200 has a plurality of cutting lines 206 designed according to user needs. In the following steps, the workpiece 200 will be cut along the cutting lines 206 with a cutting beam, wherein Figure 2A The illustrated cutting lanes are for illustration purposes only and are not intended to be limiting. The following will describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com