Fully-automatic line production cloth sticking machine

A technology of assembly line operation and cloth patching machine, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of difficult product quality assurance, high labor intensity of workers, and many technological processes, so as to shorten the process operation time, The product quality is high quality and stable, and the effect of reducing the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] Overall structure of the present invention:

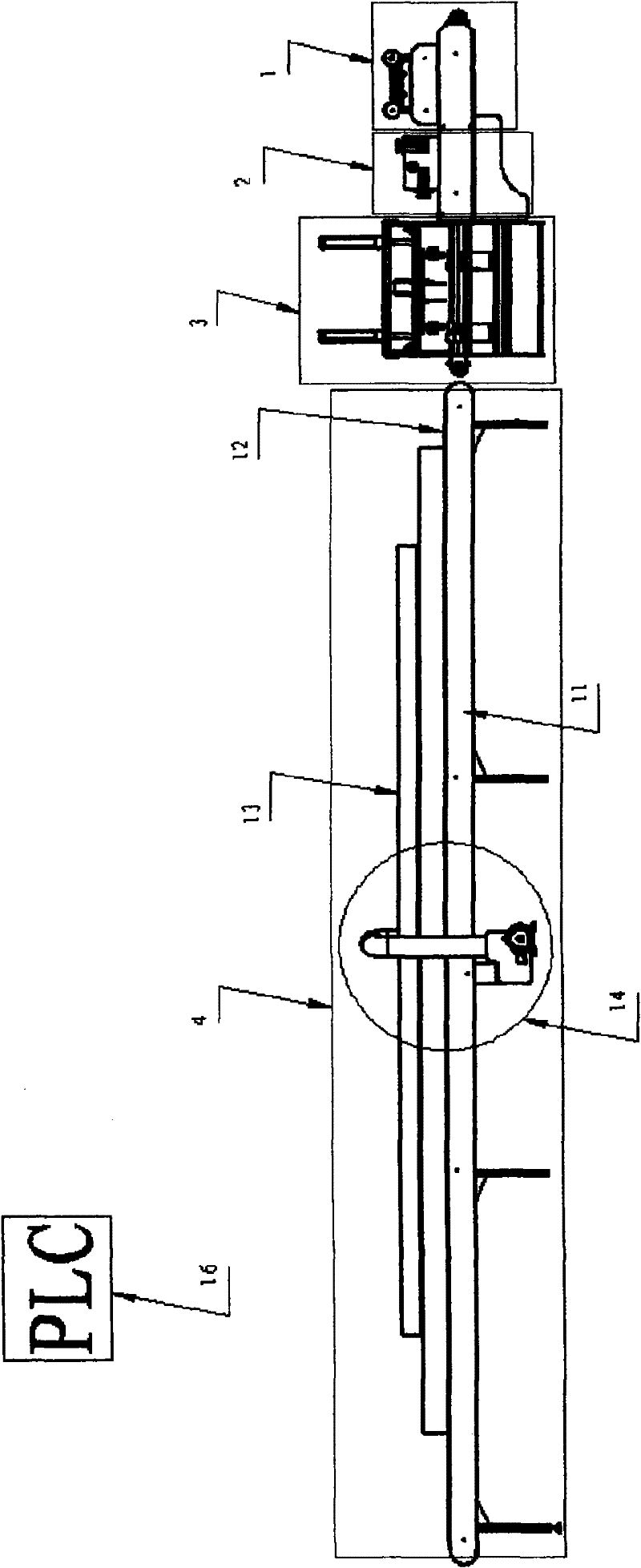

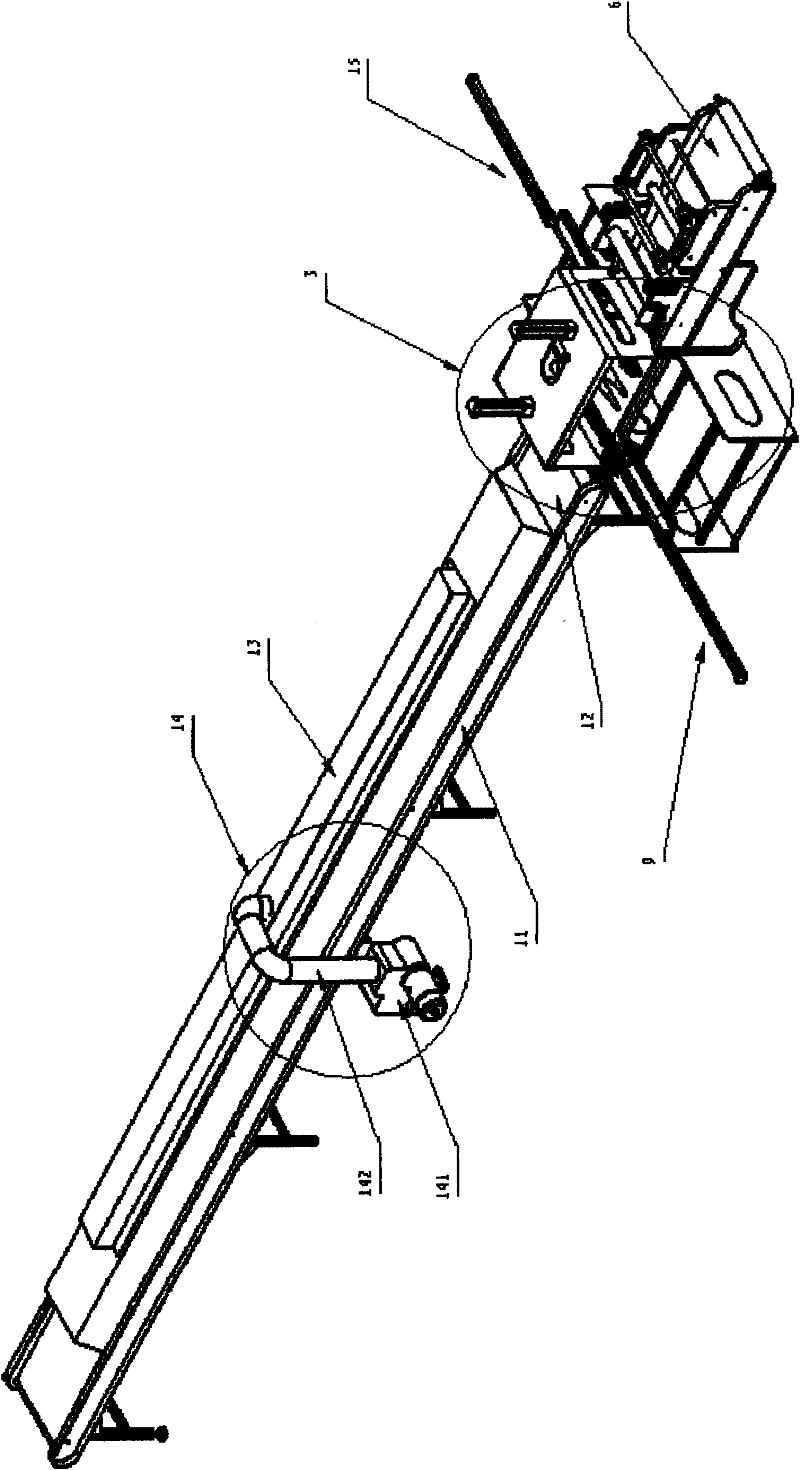

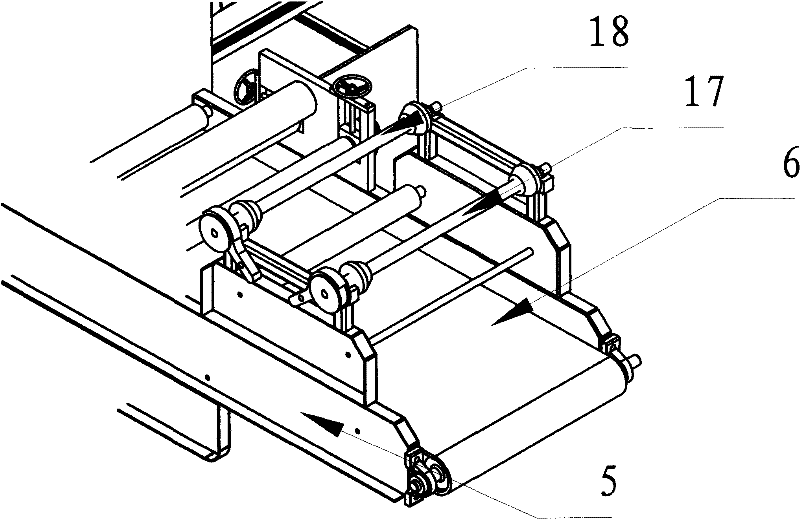

[0026] Such as figure 1 , figure 2 As shown, a full-automatic assembly machine is composed of a feeder 1, a gluing machine 2, a gluing machine 3 and a dryer 4 connected sequentially, and each part is connected with a fully automatic control system 16, and the control system 16 It is designed and manufactured by the prior art, and realizes the cooperative operation of various parts of the present invention mainly through the program in the PLC (Programmable Logic Controller). Wherein: the feeder 1 includes a frame 5, an automatic feeding belt mechanism 6, a cloth roll discharge rack 17 and a cloth roll discharge rack 18 are respectively placed on the frame 5, and the automatic feed belt mechanism 6 is placed below the discharge rack; Glue applicator 2, including frame 7, supporting roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com