High-entropy alloy, preparation method and laser cladding method

A high-entropy alloy and laser cladding technology, which is applied in the field of laser cladding, high-entropy alloy preparation, to achieve the effect of reducing material density, good weldability, hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

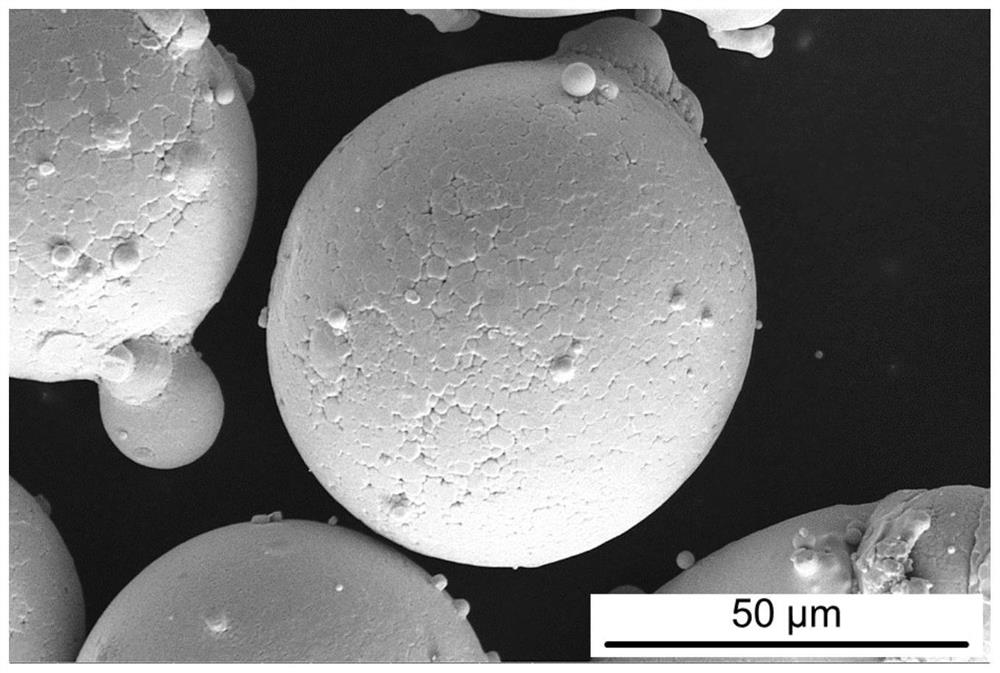

[0036] In a second aspect, an embodiment of the present invention also provides a method for preparing the above-mentioned high-entropy alloy, which includes: using a plasma rotating electrode atomization powder-making technology to prepare high-entropy alloy powder.

[0037] In an optional embodiment, the preparation of the high-entropy alloy powder includes the following steps: making a consumable electrode rod from metal, melting the rod surface of the consumable electrode rod with a plasma gun, and rotating it under the action of high-speed centrifugal force The tiny droplets are thrown out, cooled into spherical powder and collected to obtain high-entropy alloy powder.

[0038] In an optional embodiment, the preparation of high-entropy alloy powder comprises the following steps:

[0039] High-entropy alloy powders were prepared using plasma rotating electrode atomization powder-making equipment, using Fe, Co, Cr, Ni, Al and Ti as raw materials.

[0040] Step 1: Weigh Fe: 1...

Embodiment 1

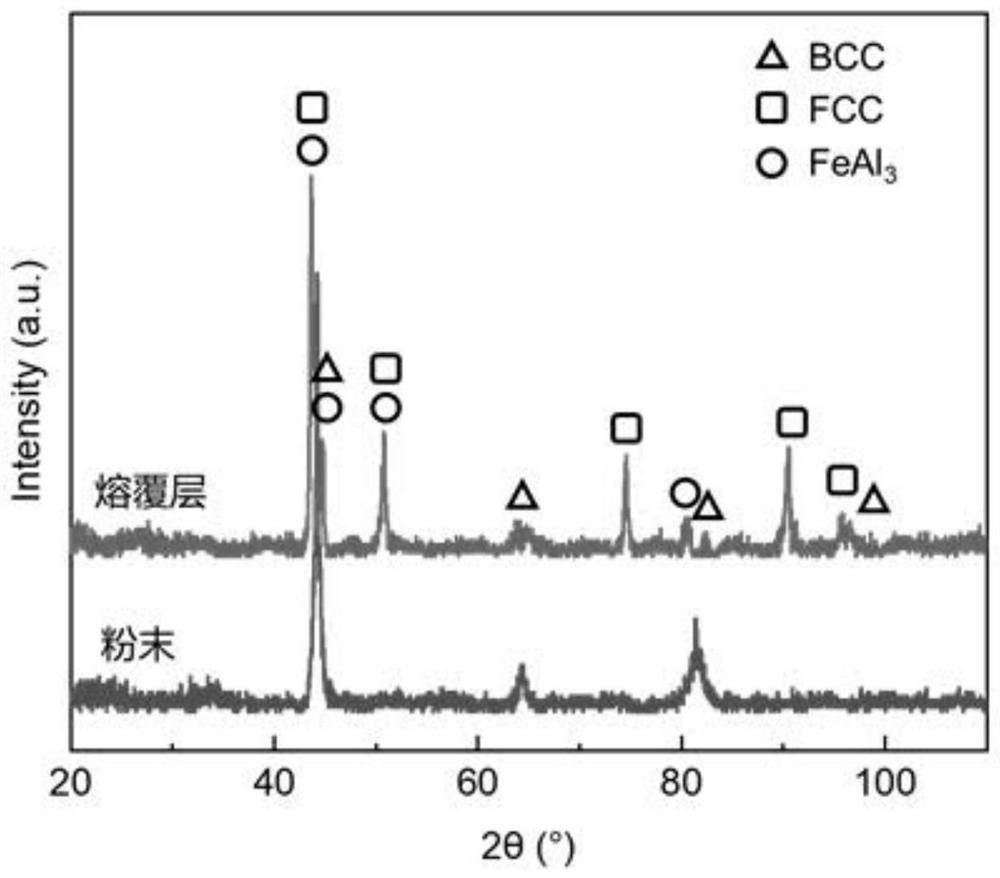

[0072] A kind of high hardness and wear-resistant FeCoCrNiAl 0.5 Ti 0.5 High-entropy alloy and its preparation method, the powder chemical composition and atomic percentage of high-entropy alloy material are: Fe: 20.00%, Co: 21.00%, Ni: 20.99%, Cr: 19.01%, Al: 10.01%, Ti: 8.99 %.

[0073] Its preparation method comprises the following steps:

[0074] Step 1: Weigh each ingot of Fe: 20.00%, Co: 21.00%, Ni: 20.99%, Cr: 19.01%, Al: 10.01%, Ti: 8.99% according to atomic percentage, melt and cool the target ingot and forged, and then processed into a consumable electrode rod with a diameter of 30 mm and a length of 150 mm for subsequent powder preparation.

[0075] Step 2: After vacuumizing the working chamber, fill it with high-purity argon (99.999 vol.%), so that the pressure in the working chamber is maintained at 0.06 MPa.

[0076] Step 3: Start the high-speed rotation mechanism to make the electrode rod rotate rapidly at a speed of 16000r / min in the gas environment of high...

Embodiment 2

[0091] The powder chemical composition of the high-entropy alloy material and its atomic percentage of the metal element are: Fe: 21.02%, Co: 22.50%, Ni: 19.99%, Cr: 18.05%, Al: 10.01%, Ti: 8.43%, powder and The cladding process parameters are basically consistent with the key parameters provided in Example 1.

[0092] The alloy material is prepared by laser cladding technology, and the mechanical properties of the obtained powder and cladding layer samples are tested:

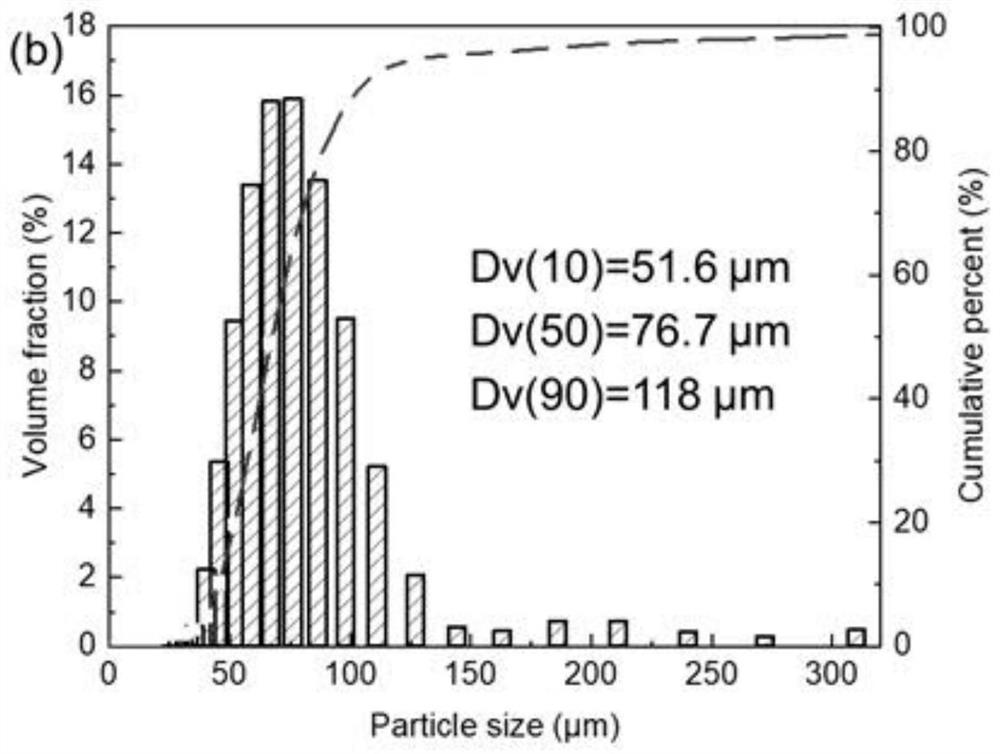

[0093] According to the GB / T 19077-2016 standard, the particle size distribution measured by MS3000 laser particle size analyzer is Dv(10)=46.1μm, Dv(50)=71.7μm, Dv(90)=111μm, which meet the requirements of commonly used powder particles for laser cladding. The range of diameter is 90-108μm.

[0094] According to the GB / T 1482-2010 standard, the powder fluidity measured by JHY-1002 Hall flow meter is 21.32s / 50g, and the bulk density is 3.89g / cm 3 Meet the requirements of laser cladding process.

[0095] Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com