Fluid-solid coupling simulation material for coal series pressure-bearing fault activation water inrush similarity test and preparation method

A technology for simulating materials and similar tests, applied in the preparation of test samples, analyzing materials, measuring devices, etc., can solve problems such as slow weakening and disintegration, failure to reflect, and unusable similar simulation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

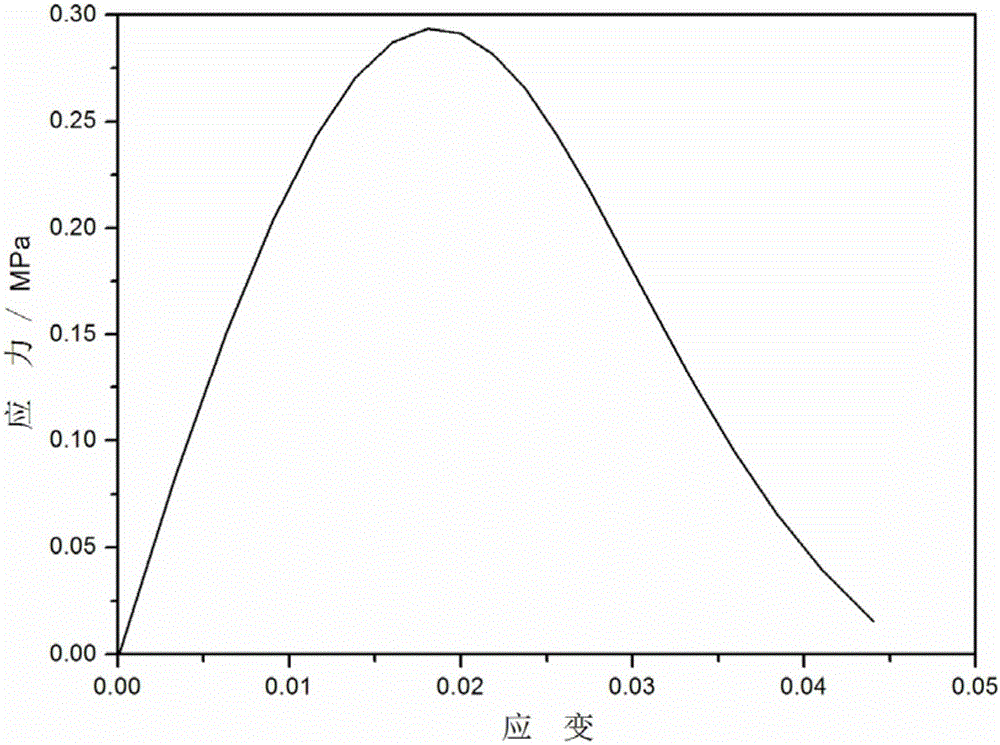

Embodiment 1

[0060] Example 1: Preparation of fluid-solid coupling simulation materials for mining coal seams in similar tests for activation of water inrush in coal-measure confined faults. The components by weight are: 1.0 parts of coal powder, 0.08 parts of talc powder, 0.8 parts of gypsum, and vaseline 0.12 part, 0.05 part of silicone oil, 0.7 part of mixing water; wherein, described coal powder, talcum powder are as aggregate, gypsum is as cementing agent, and vaseline, silicone oil, mixing water are as regulator; Its preparation method comprises the following major steps:

[0061] (1) According to the hydrogeological conditions of the fault-containing coal seam working face to be simulated and the physical and mechanical parameters and occurrence of the coal seam, determine the proportion of similar simulation materials for the mining coal seam;

[0062] (2) taking by weighing the consumption of coal powder, talcum powder, gypsum, vaseline, silicone oil and mixing water each component...

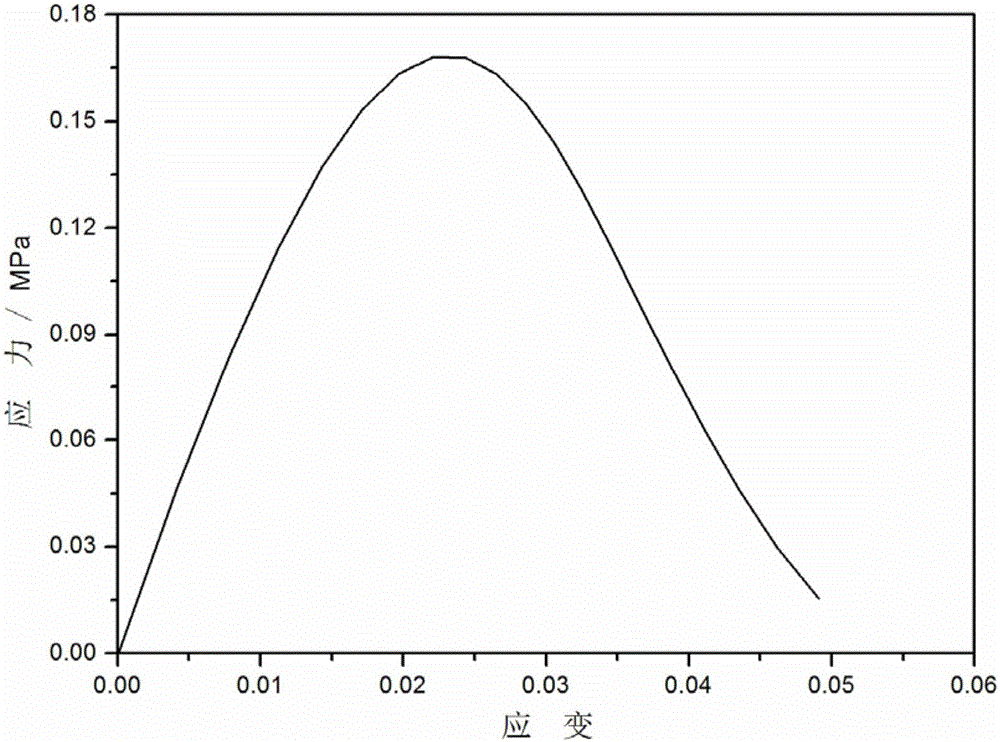

Embodiment 2

[0067]Example 2: Preparation of a pressure-bearing fault fluid-solid coupling simulation material used in a similar test of coal-measure pressure-bearing fault activation and water inrush. Its components by weight are: 1.0 parts of coarse sand, 0.22 parts of talcum powder, and 0.28 parts of gypsum , 0.3 part of kaolin, 0.21 part of vaseline, 0.12 part of silicone oil, 0.03 part of soybean, 0.13 part of mixing water; wherein, the coarse sand and talcum powder are used as aggregate, gypsum and kaolin are used as cementing agent, and vaseline, silicone oil, soybean, mixing Hydrate as regulator; Its preparation method comprises the following major steps:

[0068] (1) According to the hydrogeological conditions of the fault-containing coal seam working face to be simulated and the physical and mechanical parameters and occurrence of the fault, determine the proportion of similar simulation materials for the confined fault;

[0069] (2) Weigh the amount of coarse sand, talcum powder...

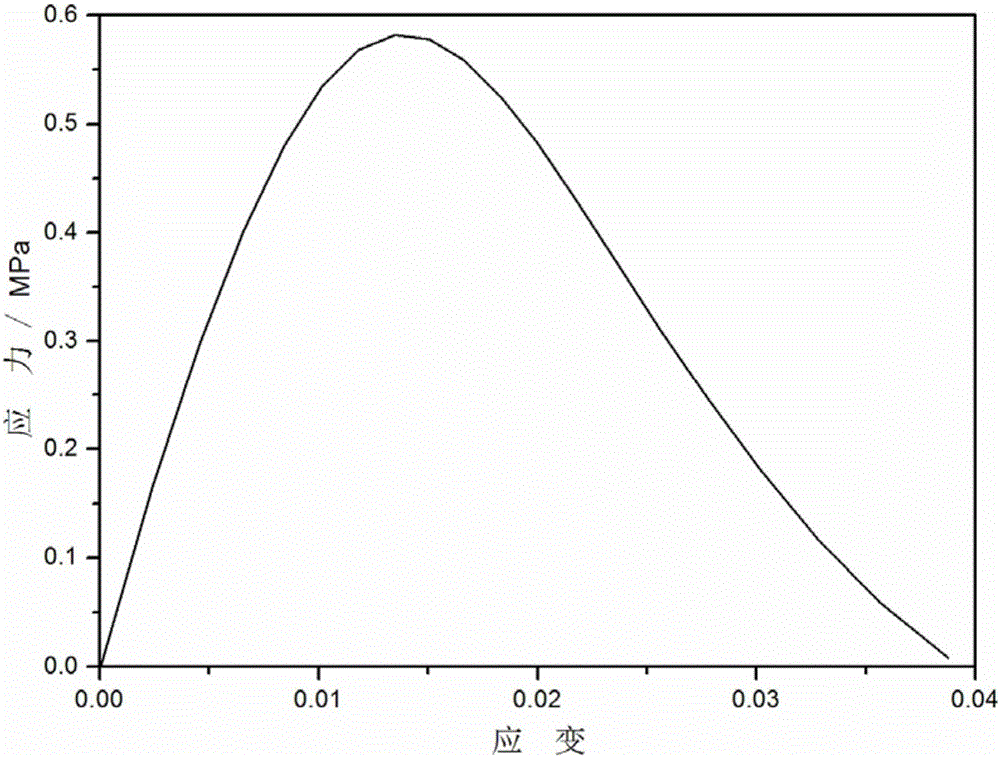

Embodiment 3

[0074] Example 3: Preparation of fluid-solid coupling simulation materials for surrounding rocks of faults used in similar tests of coal-measure confined fault activation and water inrush. Its components by weight are: 1.0 parts of fine sand, 0.08 parts of talcum powder, and 0.25 parts of gypsum , 0.1 part of kaolin, 0.06 part of cement, 0.075 part of vaseline, 0.05 part of silicone oil, and 0.1 part of water; wherein, the fine sand and talcum powder are used as aggregate, gypsum, kaolin, and cement are used as cementing agent, and vaseline, silicone oil, mixing water As regulator; Its preparation method comprises the following major steps:

[0075] (1) According to the hydrogeological conditions of the fault-containing coal seam working face to be simulated and the physical and mechanical parameters and occurrence of the coal seam roof and floor strata, determine the proportion of similar simulation materials for the fault surrounding rock; since the fault surrounding rock is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com