Four-column type rail vehicle bogie rigidity detection system

A rail vehicle and detection system technology, applied in the field of four-column rail vehicle bogie stiffness detection system, achieves the effects of saving test time and funds, broad application prospects, and shortening the research and development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with the embodiment given with accompanying drawing, the patented structure of the present invention is described in further detail.

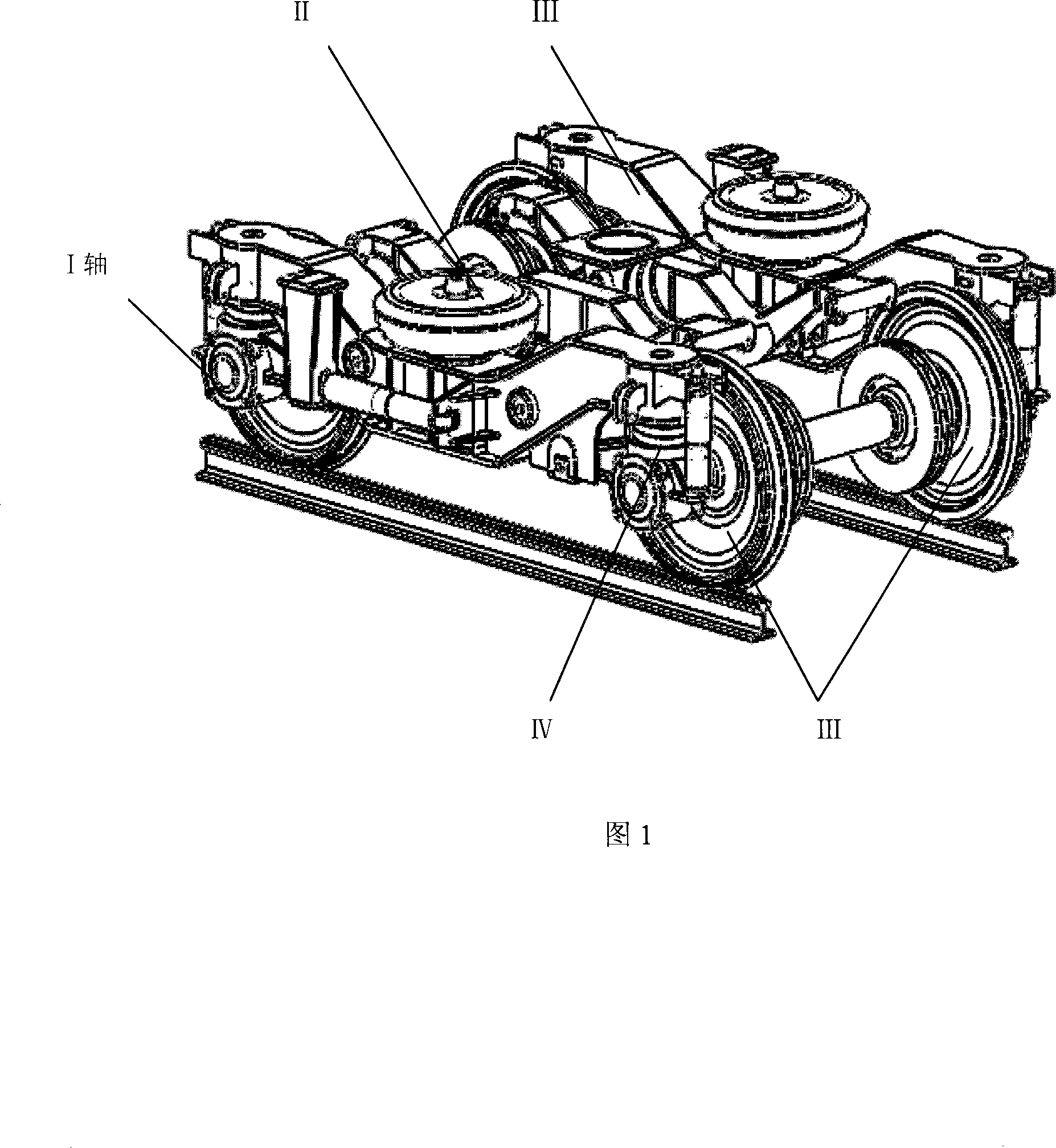

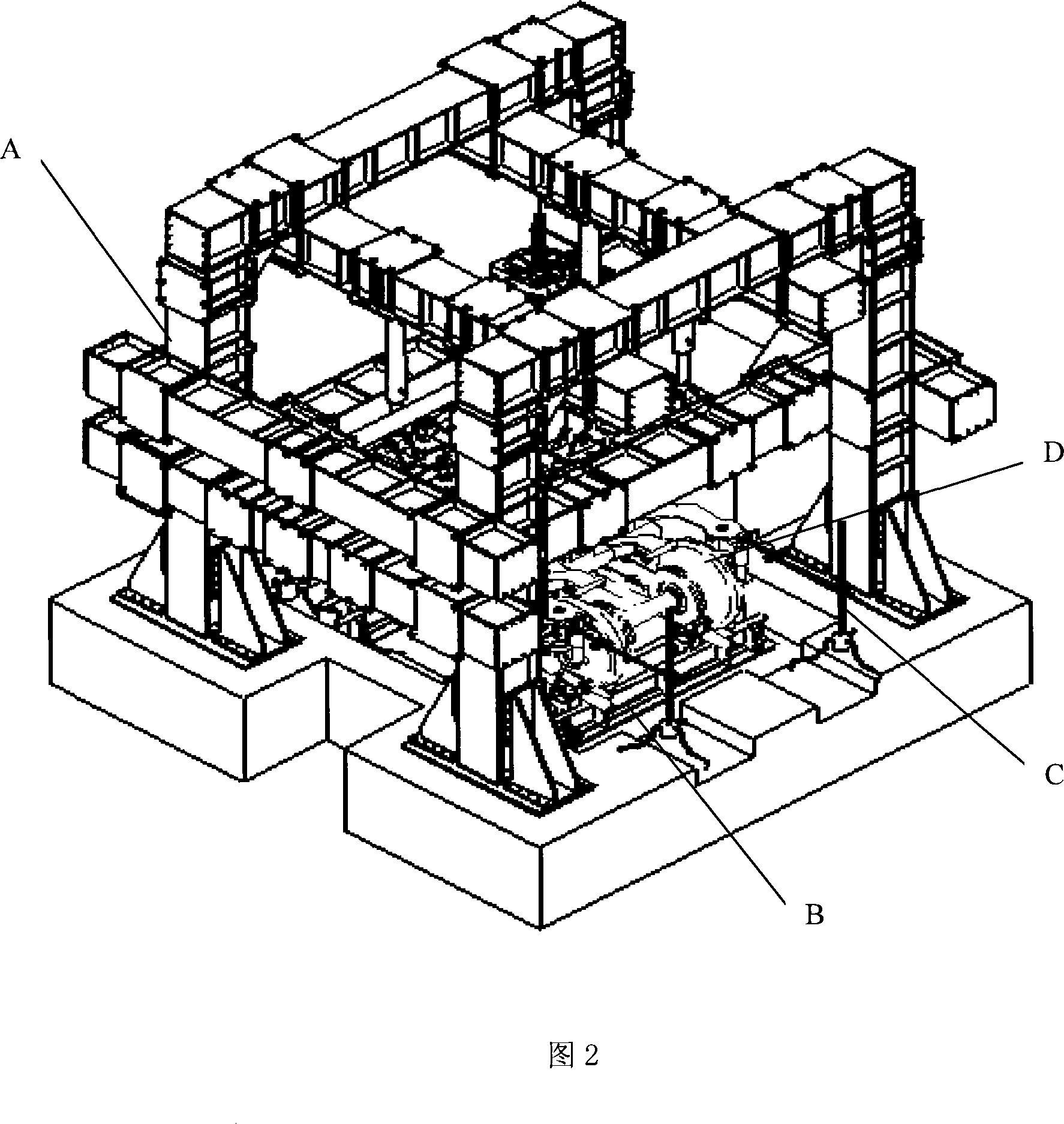

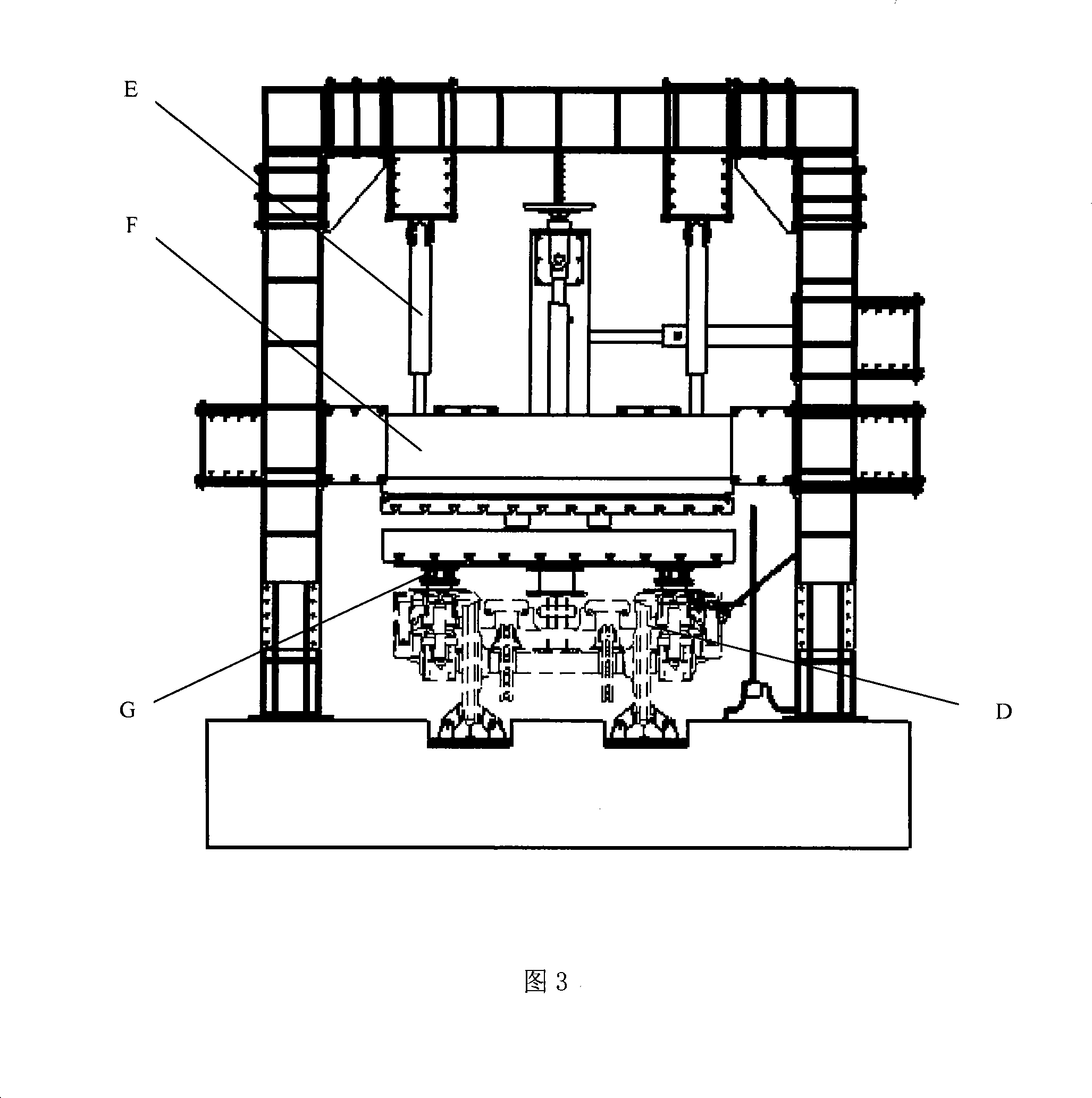

[0042] Referring to Figures 2, 3, 25, and 26, the patent of the present invention relates to a four-column rail vehicle bogie stiffness detection system, which is mainly composed of a mechanical system, a hydraulic system, a testing system, and a control system. The mechanical system mainly includes: the gantry system A is composed of nine beams 1, four columns 2 and clamping devices (see Fig. 5, 6, 7). The five-degree-of-freedom force applying system F is composed of a simulated body load pressure plate 5 , a simulated body load pressure column 4 , and a simulated body center of gravity height adjustment mechanism 3 . The wheel set positioning and clamping system B realizes the clamping and positioning function of the bogie; the hydraulic system E is composed of six vertically acting oil cylinders 7 , two longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com