U-shaped rail double-safety running and levitation driving energy-saving mechanism

A safe operation and suspension drive technology, applied in the field of rail transit, can solve the problems of low efficiency of driving linear motors, difficulty in controlling the accuracy of F-shaped steel, and small distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

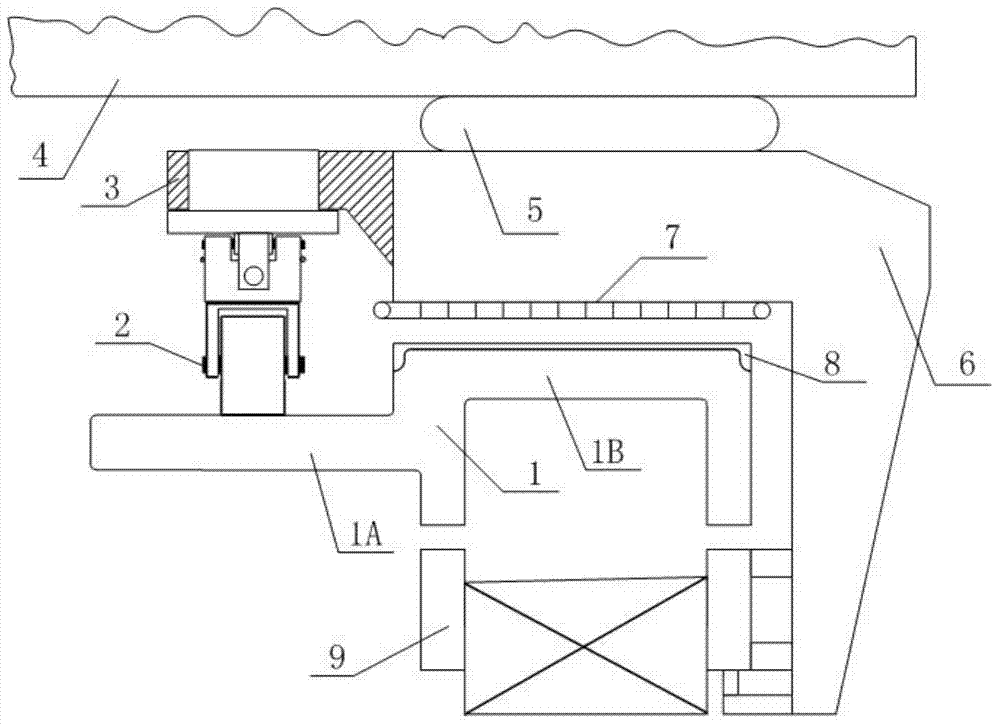

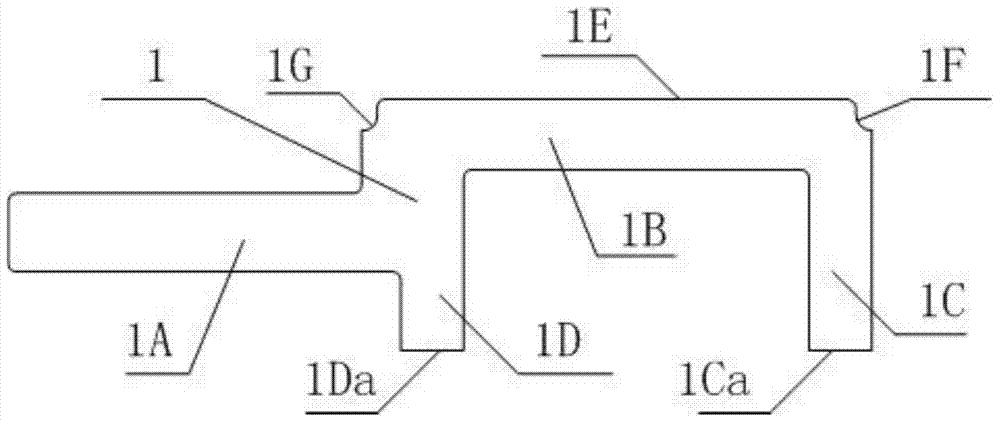

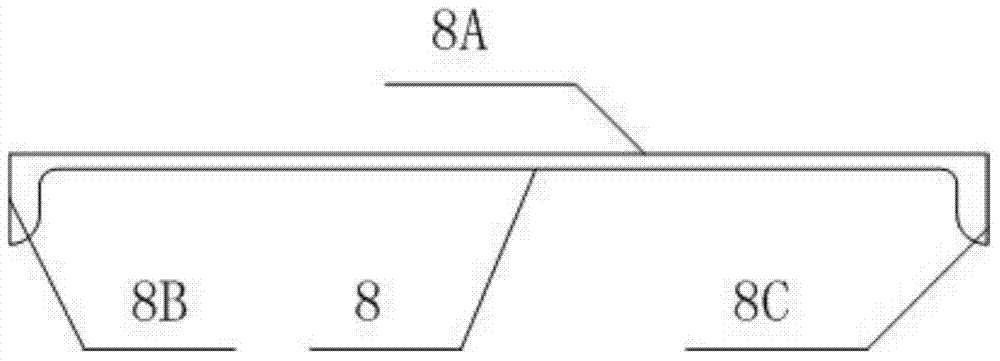

[0049] A kind of U-shaped track double backup safe operation and suspension drive energy-saving mechanism, such as figure 1 , figure 2 , image 3 with Figure 8 shown;

[0050] A U-shaped rail double-backup safe operation and suspension drive energy-saving mechanism is characterized in that it consists of a U-shaped track 1, a self-locking hydraulic travel wheel mechanism 2, a connecting frame 3, a car body 4, an air spring 5, a bogie arm 6, The spindle 7, the aluminum induction plate 8, and the levitation magnet 9 are composed. The U-shaped track 1 is installed on the sleeper or on the track beam; the aluminum induction plate 8 is installed on the outer surface of the groove bottom plate of the U-shaped track 1; Above, the bottom of the car body 4 is connected to the upper surface of the bogie arm 6 through the air spring 5, and the spindle 7 of the linear motor is installed on the lower surface of the bogie arm 6, and is completely corresponding to the aluminum inductio...

Embodiment 2

[0071] Other is with embodiment 1, and difference is:

[0072] The U-shaped track 1 is directly produced by a hot rolling process, and the corners of each part of the U-shaped track 1 are circular arcs with a radius of 1-5mm according to the requirements of the hot rolling process or performance requirements.

[0073] The distance between the upper surface of the U-shaped track installation wing plate 1A and the outer surface 1E of the groove bottom is 100 mm.

[0074] The walking wheel 2A of the double backup safe operation that is matched with U-shaped track is wear-resistant solid rubber wheel.

Embodiment 3

[0076] Other is with embodiment 1, and difference is:

[0077] The U-shaped track 1 is directly produced by a hot rolling process.

[0078] The distance between the upper surface of the mounting wing 1A and the outer surface 1E of the groove bottom is 40mm.

[0079] The walking wheel 2A of the double standby safe operation that is matched with U-shaped track is wear-resistant steel wheel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com