Semiconductor wafer, semiconductor device, and method of manufacturing semiconductor device

a semiconductor device and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device details, electric discharge tubes, etc., can solve the problems of difficult to determine, the electron beam cannot reach the alignment mark, and the excess formed, so as to achieve the effect of higher precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(1) FIRST EMBODIMENT

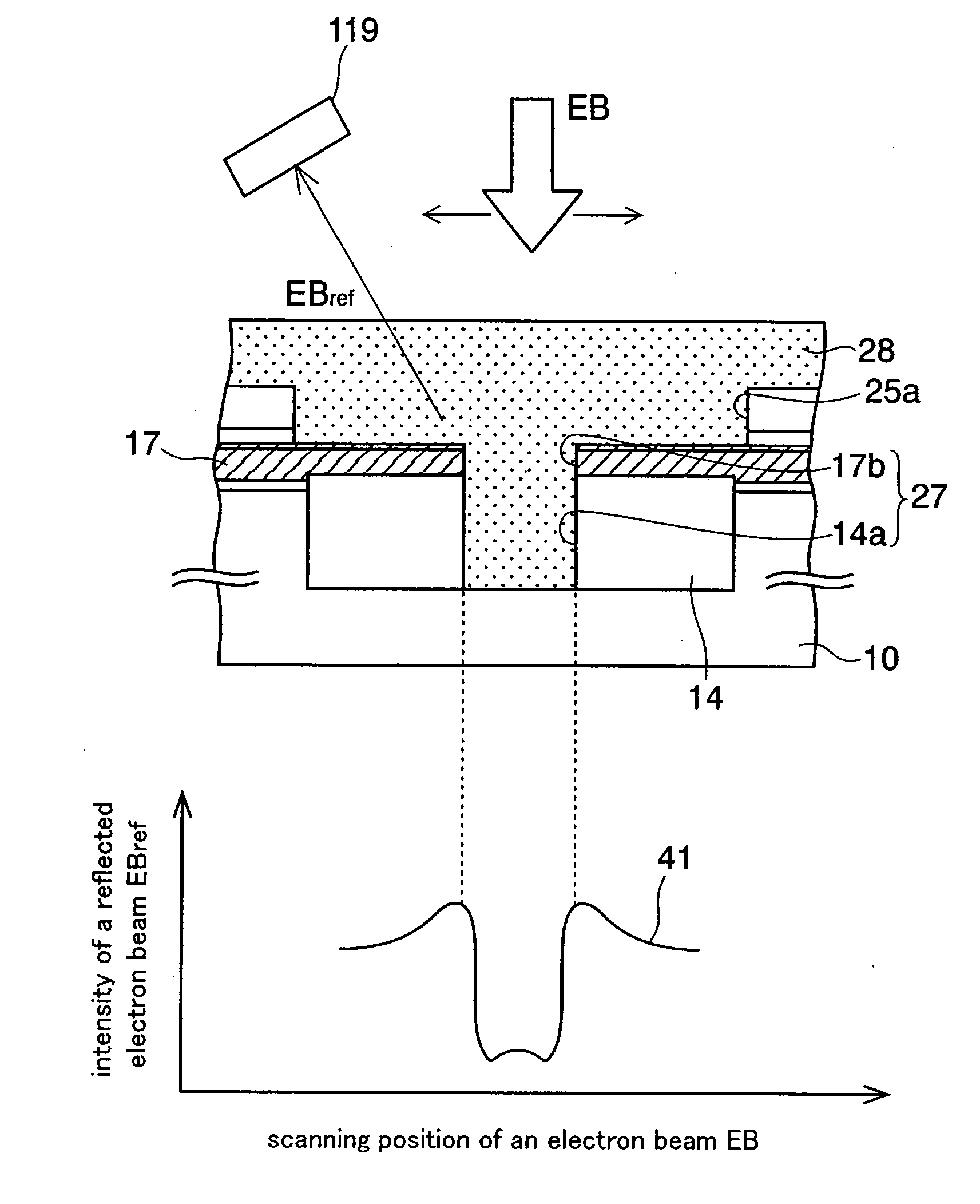

[0041]FIG. 3 is a block diagram of an electron beam exposure apparatus used in this embodiment.

[0042] This exposure apparatus includes an overall control system 101, a digital control system 106, an analog circuit 110, a machinery system 120, and an electron optics system column 113, and carries out exposure to a silicon substrate 10 inside the electron optics system column 113.

[0043] The overall control system 101 includes a control workstation 102, a display device 103 attached to this workstation, a hard disk 104, and a memory 105, and transmits / receives data to / from a digital control system 106 and the machinery system 120 via a bus 121. Such data includes, for example, a deflection data D which is generated by the control workstation 102 and determines the amount of deflection of the electron beam, which will be described hereinafter. This deflection data D is generated by the control workstation 102 depending on the shape and the size of device patterns s...

second embodiment

(2) SECOND EMBODIMENT

[0108] This embodiment differs only in the position of the first region I, in which the alignment mark 27 is formed, as compared with the first embodiment, and because the manufacturing method is the same as the first embodiment, the description regarding the manufacturing method is omitted.

[0109]FIG. 15 is a plan view of the semiconductor wafer according to this embodiment.

[0110] In the first embodiment described above, the first region I where the alignment mark 27 is formed is formed so as to be included in the scribe region. On the other hand, in this embodiment, as shown in FIG. 15, the first region is included in the chip region (the second region II).

[0111] With such an arrangement, the distance between the first region I and each point inside the chip region II becomes shorter as compared with the first embodiment in which the first region I exists outside the chip region II. It is therefore possible to correct the local positional misalignment for ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com