Loosening able plug in type joint in use for inserting to tubular insertion piece with peripheric capped edge

A technology of plug-in joints and inserts, used in mechanical equipment, couplings, etc., to solve problems such as danger and inadvertently compressing elastic rings together during installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

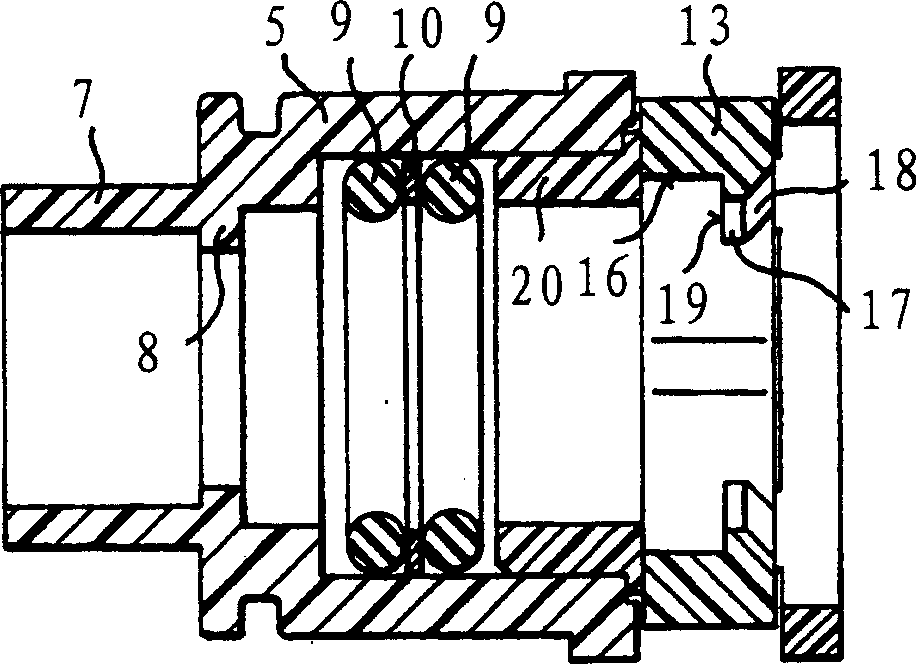

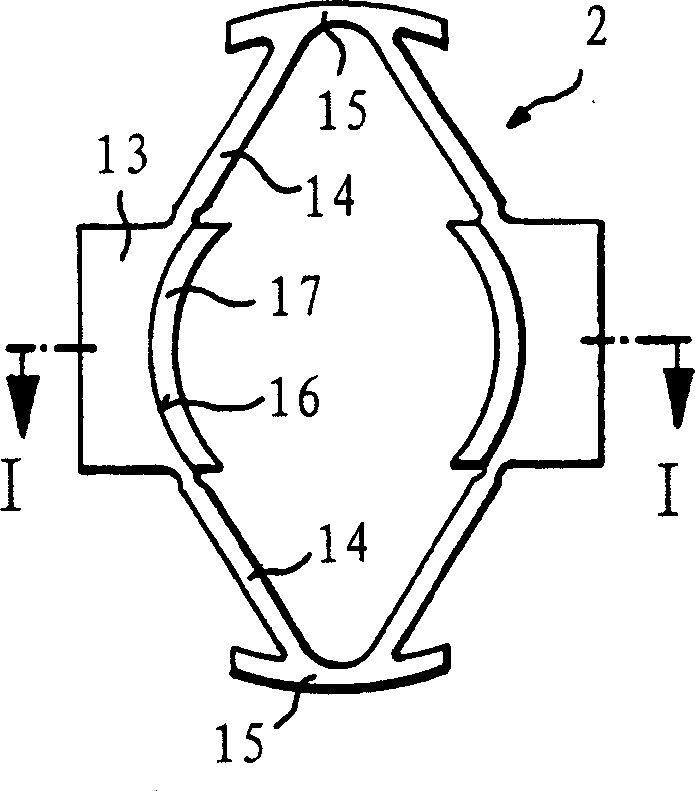

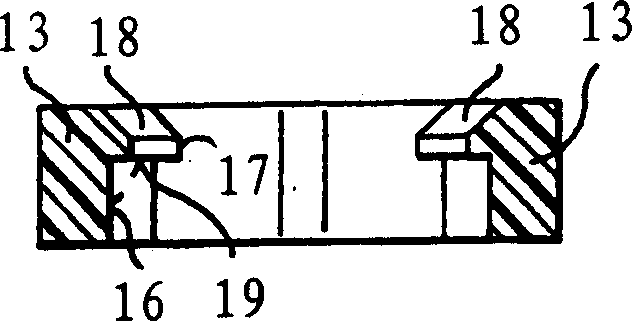

[0019] The plug-in joint shown in the figures comprises a receiving shell 1 and a locking ring or locking element 2 made of a hard elastic plastic material. The plug-in connector is designed to receive a tubular insert 3 with a peripheral rib 4, which may be the end of a catheter made of rigid material, or may be connected to a softer tube by conventional means. Ends formed by intermediate pieces in pipes made of material.

[0020] according to Figure 4 , The cylindrical shell wall 5 of the receiving shell 1 forms an inner receiving cavity 6 with several steps inside for accommodating the insert 3 . At the distal end of the receiving chamber 6, the receiving housing has a stop ring or stop ring and a cylindrical concentric connecting stub 7 for connecting the connector to a fluid connection line (not shown in the figure). The receiving cavity 6 starts from the opposite side of the inlet end and is an inner cavity 6', the inner diameter of the inner cavity corresponds to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com