Composite efficient cyanobacteria-eutrophication water treatment agent

A technology of eutrophication water and treatment agent, applied in adsorption water/sewage treatment, ion-exchanged water/sewage treatment, other chemical processes, etc., can solve the problems that have not been found yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

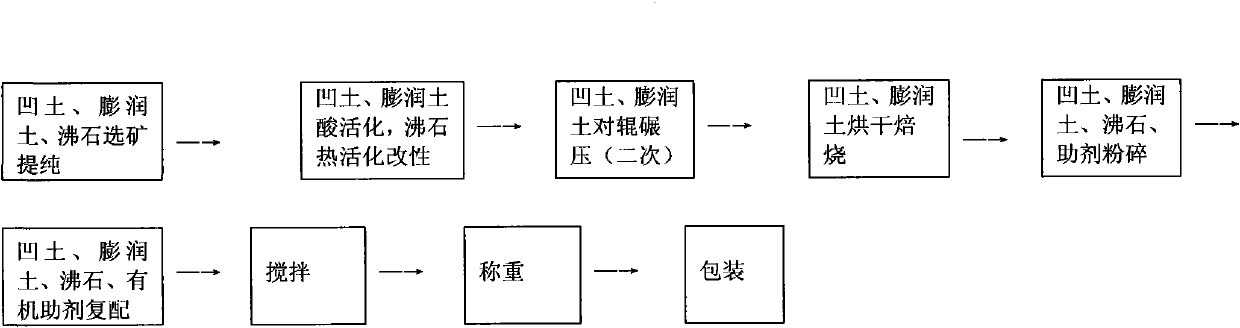

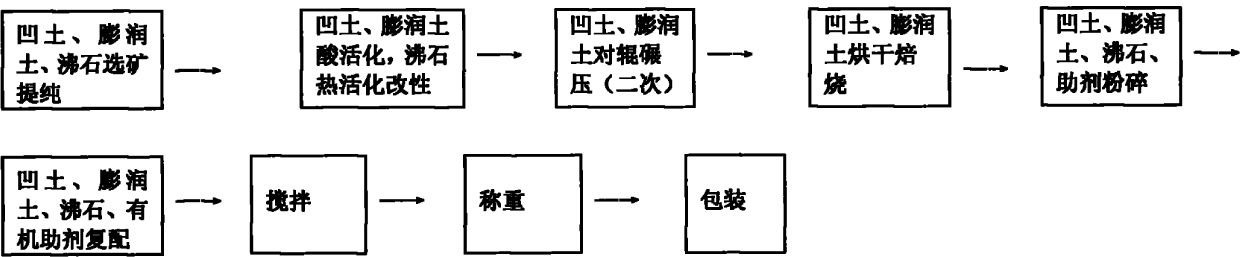

Image

Examples

Embodiment 1

[0015] Embodiment 1: at first get raw material: ore such as attapulgite, bentonite, natural zeolite, carry out ore dressing purification: the ore containing attapulgite, montmorillonite and zeolite high attapulgite clay, bentonite and natural zeolite ore are left, put The gangues of non-attapulgite clay, non-bentonite and non-zeolite were detected, so that their contents were all above 70%. Then prepare a solution containing (by weight percentage) 8% sulfuric acid and spray it on the attapulgite and bentonite, stir evenly, and age for 8 hours to become activated attapulgite clay and activated bentonite. Roll the activated attapulgite clay and the activated bentonite to rollers twice respectively, and the thickness of the pressed sheet is about 1mm; to activate them again. Put the secondary activated attapulgite clay and activated bentonite into a drying roaster or a rotary kiln for drying and roasting at temperatures of 100-250°C and 100-350°C respectively; for 1-2 hours, acti...

Embodiment 2

[0016] Embodiment 2: Get raw materials: ores such as attapulgite, bentonite, natural zeolite, carry out ore dressing purification: leave the ore containing attapulgite, montmorillonite and zeolite high, and put non-attapulgite clay, non-bentonite and non-zeolite The gangues are detected, so that their content respectively reaches more than 70%. Prepare (by weight percentage) 9% sulfuric acid solution, spray on attapulgite and bentonite, stir evenly, and age for 6 hours to become activated attapulgite clay and activated bentonite. The activated attapulgite clay and the activated bentonite are respectively rolled twice on rollers, and the thickness of the pressed sheet is about 1.5mm, so that they are activated again. Put the activated attapulgite clay and activated bentonite in a drying and roasting furnace or a rotary kiln for drying and roasting at temperatures of 100-250°C and 100-350°C respectively; for 1-2 hours, activate them three times. Activation and modification of z...

Embodiment 3

[0017] Embodiment 3: get raw material: ore such as attapulgite, bentonite, natural zeolite, carry out ore dressing purification: leave the ore containing attapulgite, montmorillonite and zeolite high, put non-attapulgite clay, non-bentonite and non-zeolite The gangues are detected, so that their content respectively reaches more than 70%. Prepare a solution containing (by weight percentage) 10% sulfuric acid, spray it on attapulgite and bentonite, stir evenly, and age for 4 hours to become activated attapulgite clay and activated bentonite. The activated attapulgite clay and the activated bentonite are respectively rolled twice to the rollers, and the thickness of the pressed sheet is about 1-2mm; to activate them again. Put the activated attapulgite clay and activated bentonite in a drying and roasting furnace or a rotary kiln for drying and roasting at temperatures of 100-250°C and 100-350°C respectively; for 1-2 hours, activate them three times. Activation and modification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com