Method and device for collecting and treating sludge in shallow lake

A sludge and lake technology, which is applied in the field of collecting and processing shallow lake sludge and equipment, can solve the problems of secondary pollution of the environment, floating mud cannot be sucked up, drifting to other places, etc., and achieve the effect of reducing treatment costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

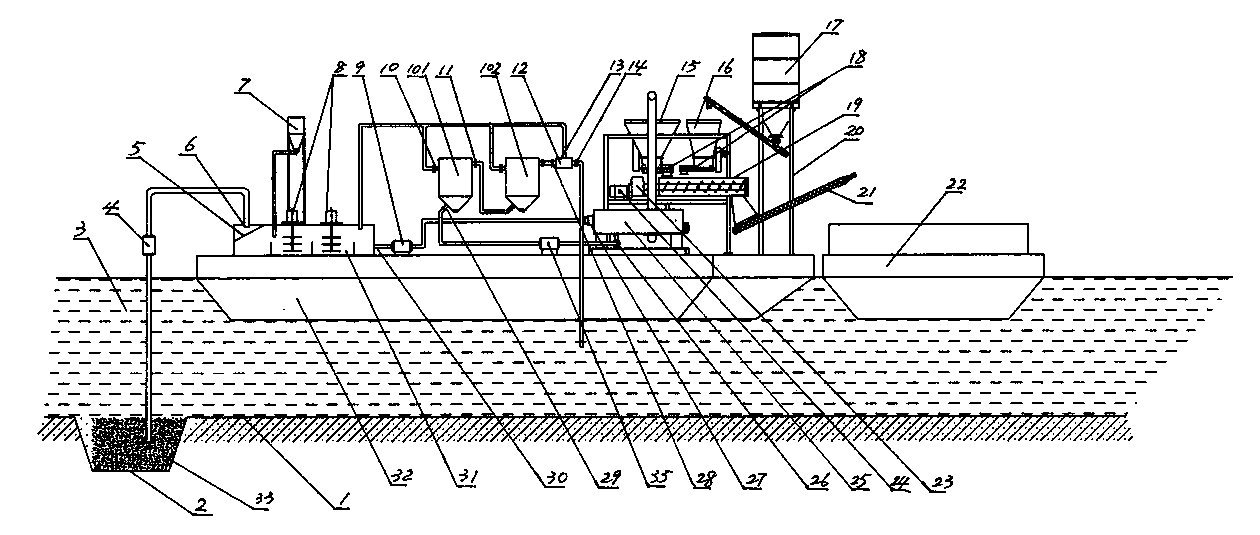

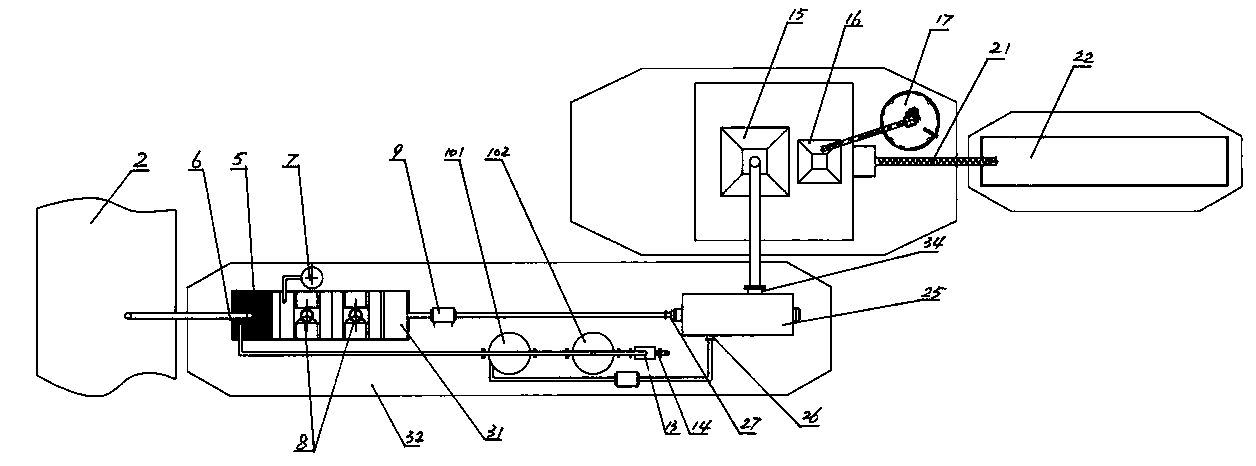

[0026] The method for collecting and processing shallow lake silt of the present invention is described in further detail below in conjunction with embodiment:

[0027] The method of collecting and processing shallow lake silt of the present invention comprises the following steps successively:

[0028] Excavate ridges 2 on the lake bottom 1 in advance, and the ridges 2 are arranged in a staggered shape, so that there is a relatively large angle (preferably 90 degrees) between the longitudinal direction of the ridges 2 and the perennial lake flow direction, so as to make the lake bottom float. Mud can enter the ditch 2 under the action of the lake current. Wherein, the number of the furrows is determined according to needs, and in this embodiment, there are five furrows in the same direction (ie, horizontal and vertical).

[0029] When the silt in the ditch 2 is full and needs to be removed, a floating platform 32 and a mud ship 22 are arranged on the lake near the ditch 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com