Method for preparing silver-carried silica microsphere functional materials

A technology of silicon dioxide and functional materials, which is applied in the preparation of silver-silica microsphere functional materials and the preparation of silver-loaded microsphere materials. High efficiency, simple operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

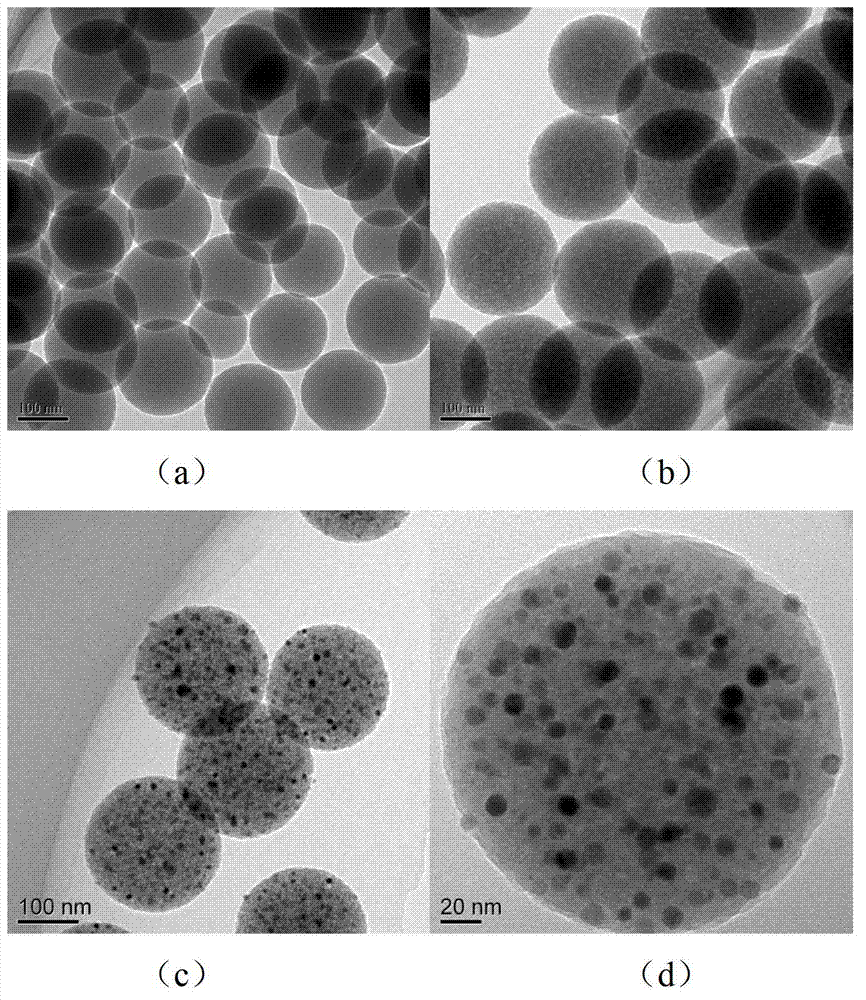

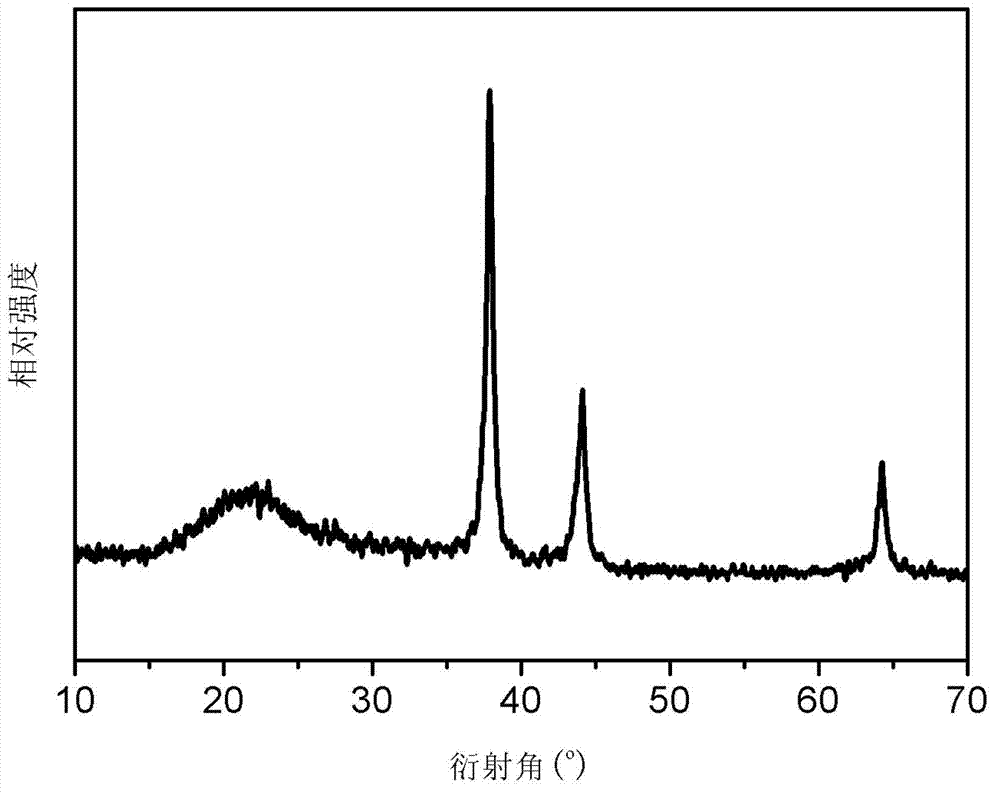

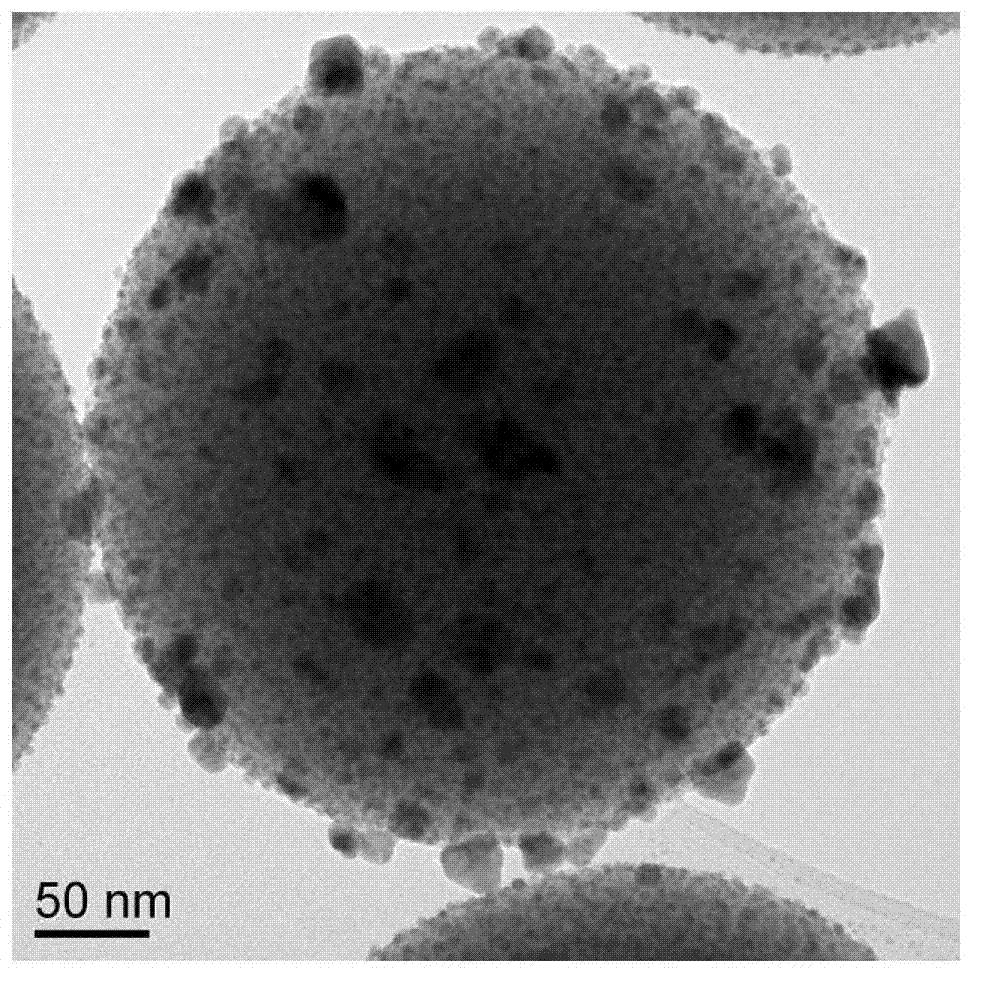

[0028] Add 18 mL of tetraethyl orthosilicate into a mixed solvent composed of 260 mL of absolute ethanol and 99 mL of deionized water, and stir magnetically. Add 18mL of ammonia water (25%~28%) to the mixture under stirring, and continue stirring for 12h. Centrifuge and wash sequentially with absolute ethanol and deionized water. Then dry in an oven at 80°C to obtain a pure white powder. Disperse 0.8g of pure white powder in 80mL of deionized water and ultrasonically disperse for 20min. Then 3 g of polyvinylpyrrolidone was added thereto, and magnetically stirred for 3 h at room temperature. Finally, the mixed solution was placed in a water bath at 30° C., and 40 mL (2.0 g / 100 mL) of NaOH solution was added thereto, stirred by magnetic force, and reacted for 1 h. The solution was centrifuged and washed successively with absolute ethanol and deionized water. That is, a white powder was obtained. Disperse 0.5 g of the above white powder in 40 mL of absolute ethanol, add 100 ...

Embodiment 2

[0030] Add 18 mL of tetraethyl orthosilicate into a mixed solvent composed of 260 mL of absolute ethanol and 99 mL of deionized water, and stir magnetically. Add 18mL of ammonia water (25%~28%) to the mixture under stirring, and continue stirring for 12h. Centrifuge and wash sequentially with absolute ethanol and deionized water. Then dry in an oven at 80°C to obtain a pure white powder. Disperse 0.4g of pure white powder in 40mL of deionized water and ultrasonically disperse for 20min. Then 6 g of polyvinylpyrrolidone was added thereto, and magnetically stirred for 3 h at room temperature. Finally, the mixed solution was placed in a water bath at 20°C, and 40 mL (2.0 g / 100 mL) of sodium borohydride solution was added thereto, stirred by magnetic force, and reacted for 1 h. The solution was centrifuged and washed successively with absolute ethanol and deionized water. That is, a white powder was obtained. Disperse 0.5 g of the above white powder in 40 mL of absolute ethan...

Embodiment 3

[0032]Add 18 mL of tetraethyl orthosilicate into a mixed solvent composed of 260 mL of absolute ethanol and 99 mL of deionized water, and stir magnetically. Add 18mL of ammonia water (25%~28%) to the mixture under stirring, and continue stirring for 12h. Centrifuge and wash sequentially with absolute ethanol and deionized water. Then dry in an oven at 80°C to obtain a pure white powder. Disperse 0.8g of pure white powder in 80mL of deionized water and ultrasonically disperse for 20min. Then 6 g of polyvinylpyrrolidone was added thereto, and magnetically stirred for 3 h at room temperature. Finally, the mixed solution was placed in a water bath at 60°C, and 40 mL (2.0 g / 100 mL) of NaOH solution was added thereto, stirred by magnetic force, and reacted for 1 h. The solution was centrifuged and washed successively with absolute ethanol and deionized water. That is, a white powder was obtained. Disperse 0.5 g of the above white powder in 40 mL of absolute ethanol, add 100 mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com