Sealed small low-impact release screw bolt

A technology of unlocking bolts and low impact is applied in the field of pyrotechnic connection and separation devices, which can solve the problems of weak sealing, large separation impact, unsatisfactory structural size and bearing capacity, etc., and achieves low impact, strong connection and good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

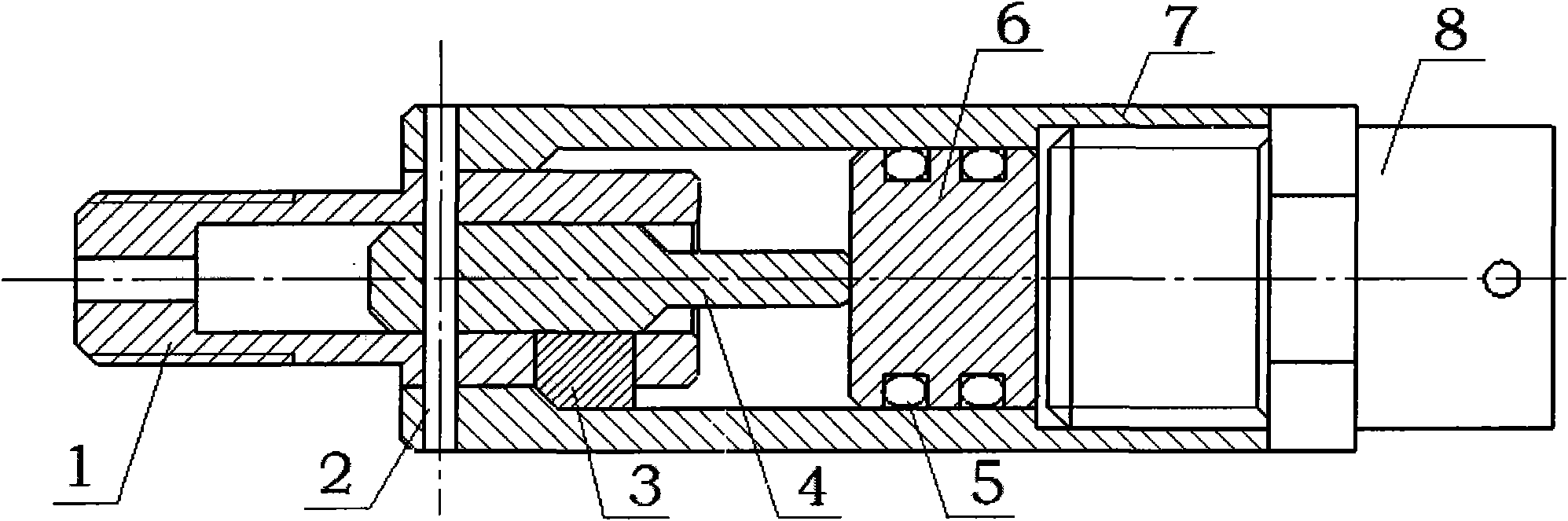

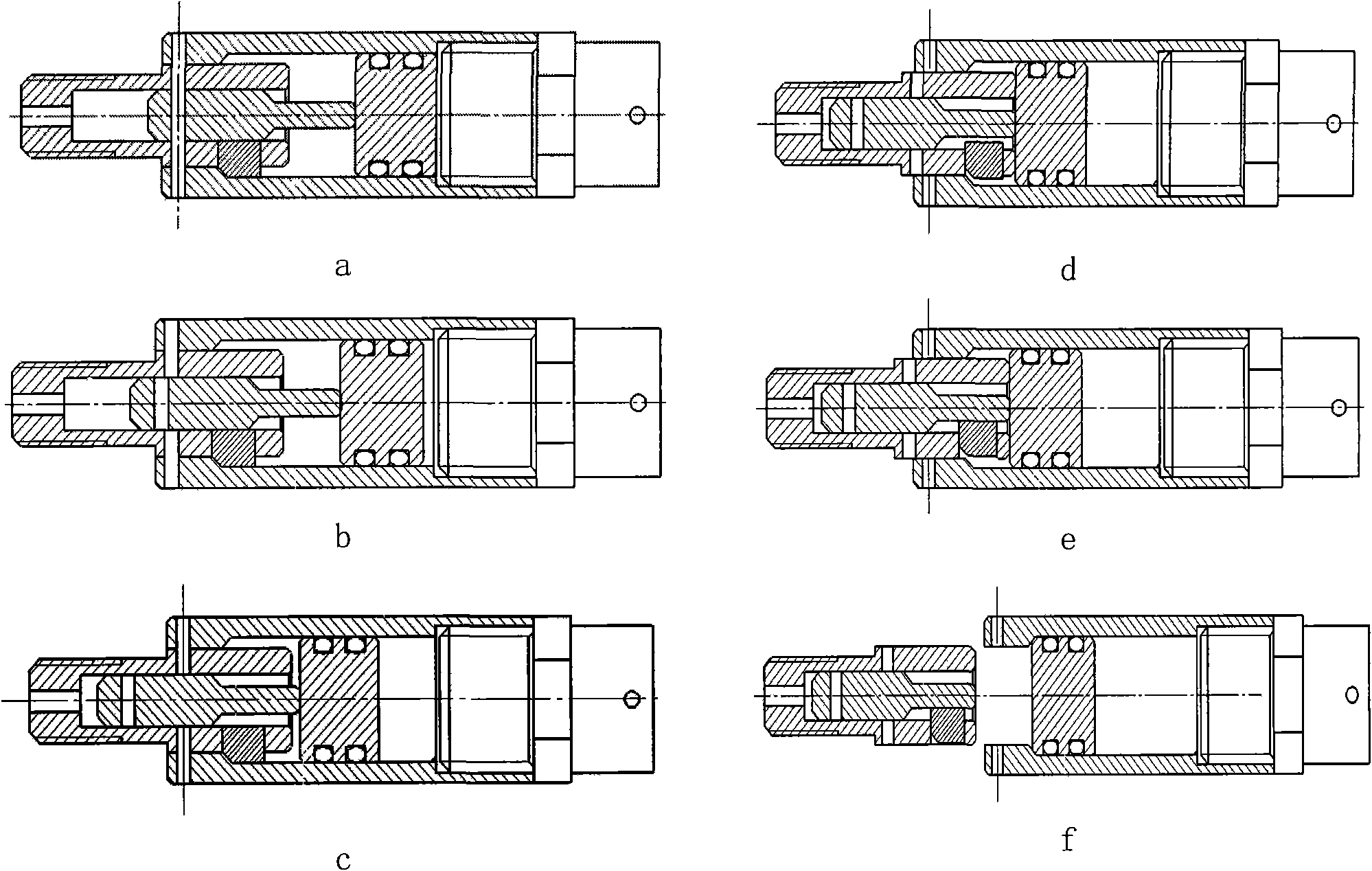

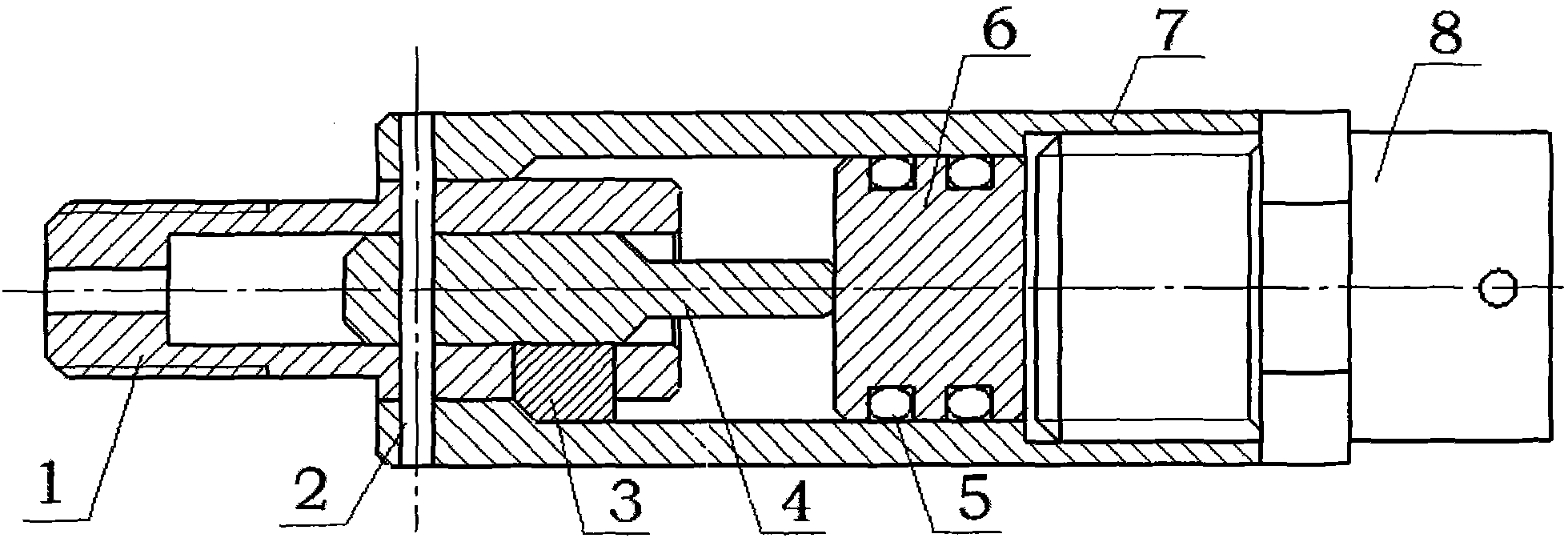

[0012] (1) Select high-strength materials, and preliminarily design a pyrotechnic unlocking bolt separation device; on the premise of ensuring that the connection strength of a single device is above 12kN, based on the optimization design idea, the dimensions of each part are adjusted through the self-compiled Matlab program And the number is gradually optimized. According to the optimization results, three metal wedges distributed in the circumferential direction of 1200 are finally used as the connection mechanism between the outer cylinder and the inner cylinder, so that after the device is fully assembled, the total length is 52.5mm (excluding the electric initiator), and the maximum outer diameter is 16mm. Device miniaturization. (2) By embedding a double O-ring sealing baffle inside the device, before the device of the present invention is separated, the piston and the double O-ring sealing baffle contact and cooperate; after separation, the piston is separated from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com