Anti-pollution cyclodextrin-polymer composite nano-filtration membrane and preparation method thereof

A composite nanofiltration membrane and cyclodextrin technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of mild reaction conditions, stable structure, good separation and anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

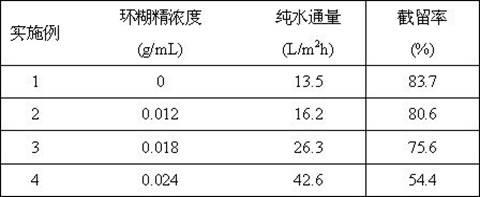

Embodiment 1-4

[0034] (1) Preparation of oil phase solution: Dissolve trimesoyl chloride in n-hexane to prepare a solution with a concentration of 0.006 g / mL;

[0035] (2) Preparation of the aqueous phase solution: the concentration of triethanolamine is 0.06 g / mL, the concentration of sodium lauryl sulfate is 0.003 g / mL, and NaOH / Na 2 CO 3 (mass ratio 1:2) an aqueous solution with a concentration of 0.006 g / mL, and then dissolve β-cyclodextrin with a concentration of 0 to 0.024 g / mL in the above solution;

[0036] (3) Immerse the wet polysulfone support membrane in the oil phase solution for 30 minutes, take it out, roll the surface of the support membrane with a rubber roller, and squeeze it dry; immerse the support membrane in the water phase solution, the reaction time is 35 minutes, and take it out; The film was immersed in the oil phase solution, and the reaction time was 35 minutes. After the composite film was naturally dried in the air for 1 minute, it was dried at 60 o Heat trea...

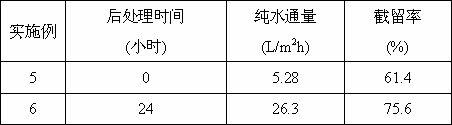

Embodiment 5-6

[0042] (1) preparation of oil phase solution: with embodiment 1-4;

[0043] (2) Preparation of the aqueous phase solution: the concentration of triethanolamine is 0.06 g / mL, the concentration of sodium lauryl sulfate is 0.003 g / mL, and NaOH / Na 2 CO 3 (mass ratio 1:2) an aqueous solution with a concentration of 0.006 g / mL, and then β-cyclodextrin with a concentration of 0.018 g / mL dissolved in the above solution;

[0044] (3) with embodiment 1-4;

[0045] (4) Immerse the above composite membrane in an aqueous solution containing 0.001 g / mL sodium dodecyl sulfate at pH = 11 for 0-24 hours, and then rinse with water. A cyclodextrin-polyester composite nanofiltration membrane is obtained. Its desalination performance was tested under the conditions of 5mmol / L sodium sulfate aqueous solution and operating pressure of 0.6 MPa.

[0046] These several examples are to investigate the effect of post-treatment time on membrane performance.

[0047]

[0048] From Examples 5-6, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com