Lithium-sulfur battery sulfur/carbon composite positive electrode material, preparation method and applications thereof

A technology for lithium-sulfur batteries and positive electrode materials, which can be used in battery electrodes, lithium batteries, non-aqueous electrolyte battery electrodes, etc., can solve problems such as atmospheric environmental pollution, and achieve the effect of simple method, improvement of environmental pollution problems, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

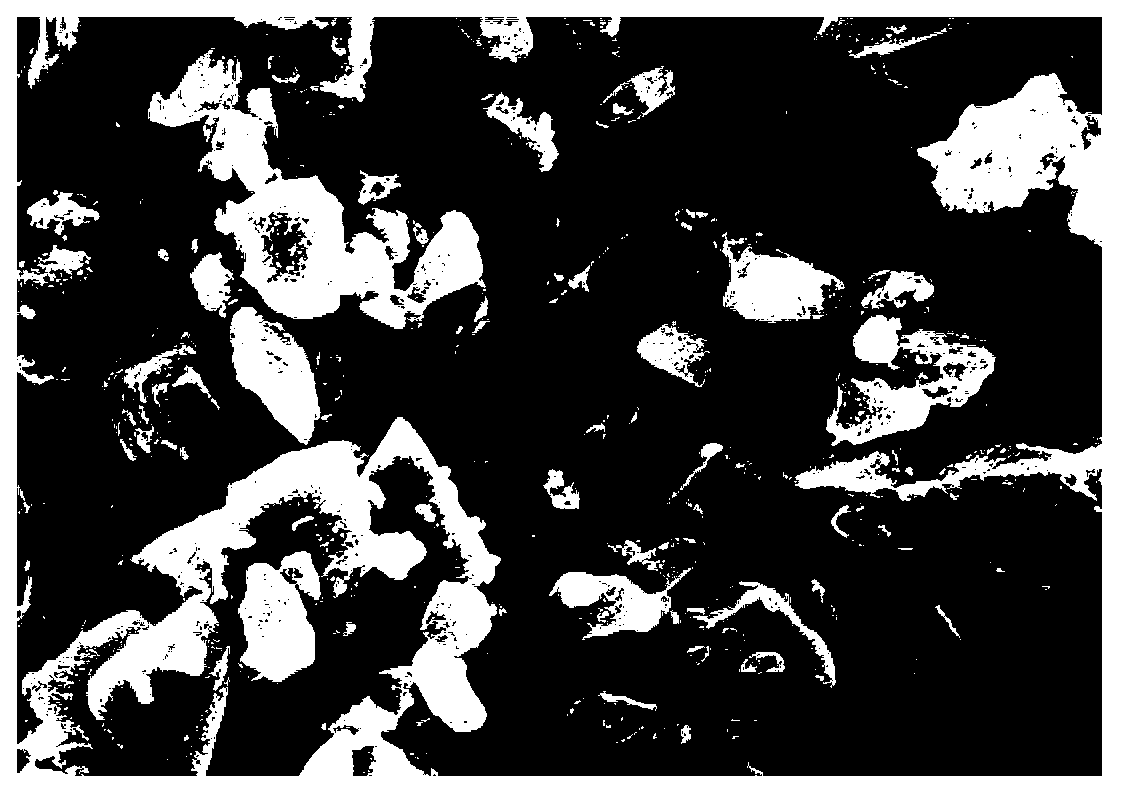

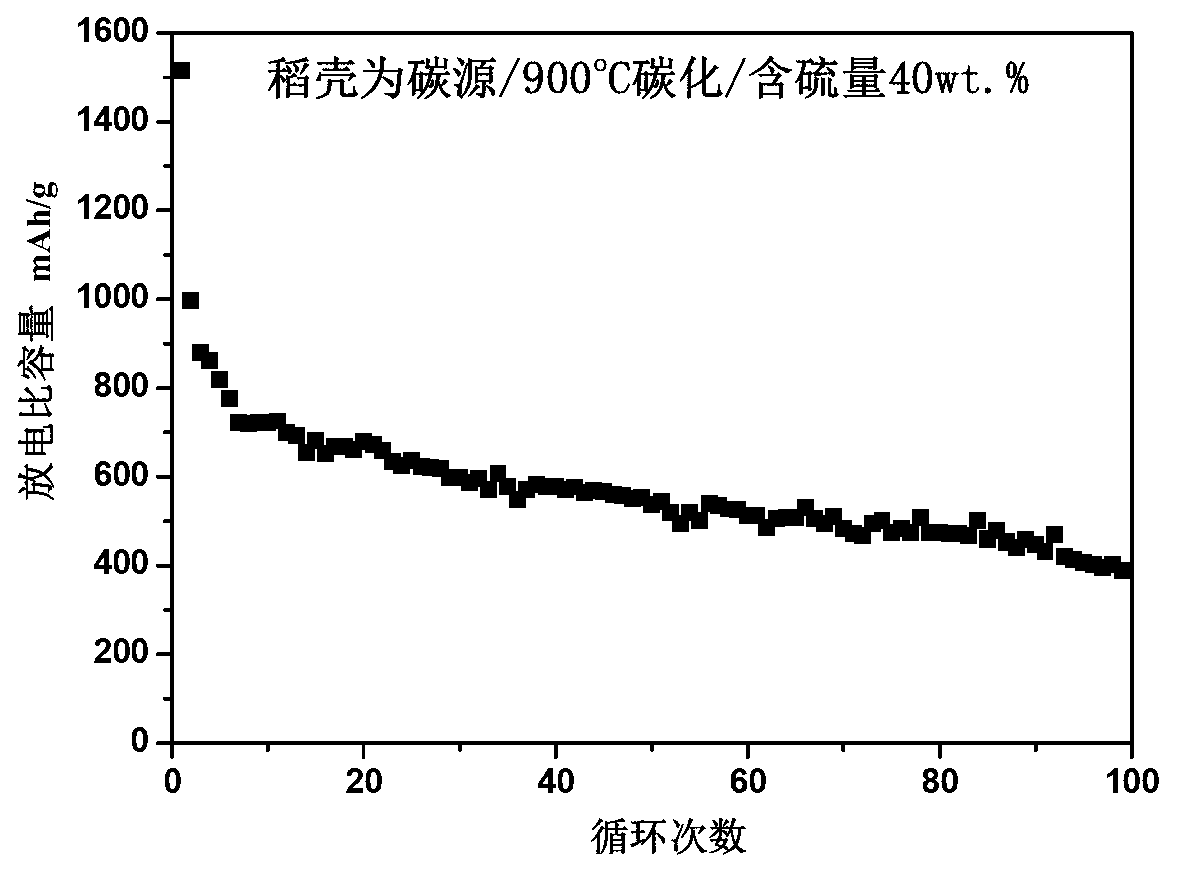

[0043] Preparation of sulfur / carbon composite material: After washing and drying rice husks, carbonization treatment was carried out at 900° C. for 1 hour under an argon atmosphere. The cooled carbonized rice husk is ground and pulverized into 100 nm-50 μm particles. The powder material was stirred in 0.5 mol / L sodium hydroxide solution at room temperature for 4 hours to remove silicon oxides in the carbonized product. After filtering the sodium hydroxide solution to obtain the carbon material, and after further washing with water, the carbon material is dried, and the scanning electron microscope photo is as follows: figure 1 As shown, the specific surface area of the prepared sample reaches 1000 m 2 / g or more. The dried carbon material and sulfur are mixed evenly according to the mass ratio of 3:2, and then the mixture is heated to 100°C under vacuum conditions, kept for 24 hours, and the sulfur / carbon composite material is obtained after cooling. The content of sulfur...

Embodiment 2

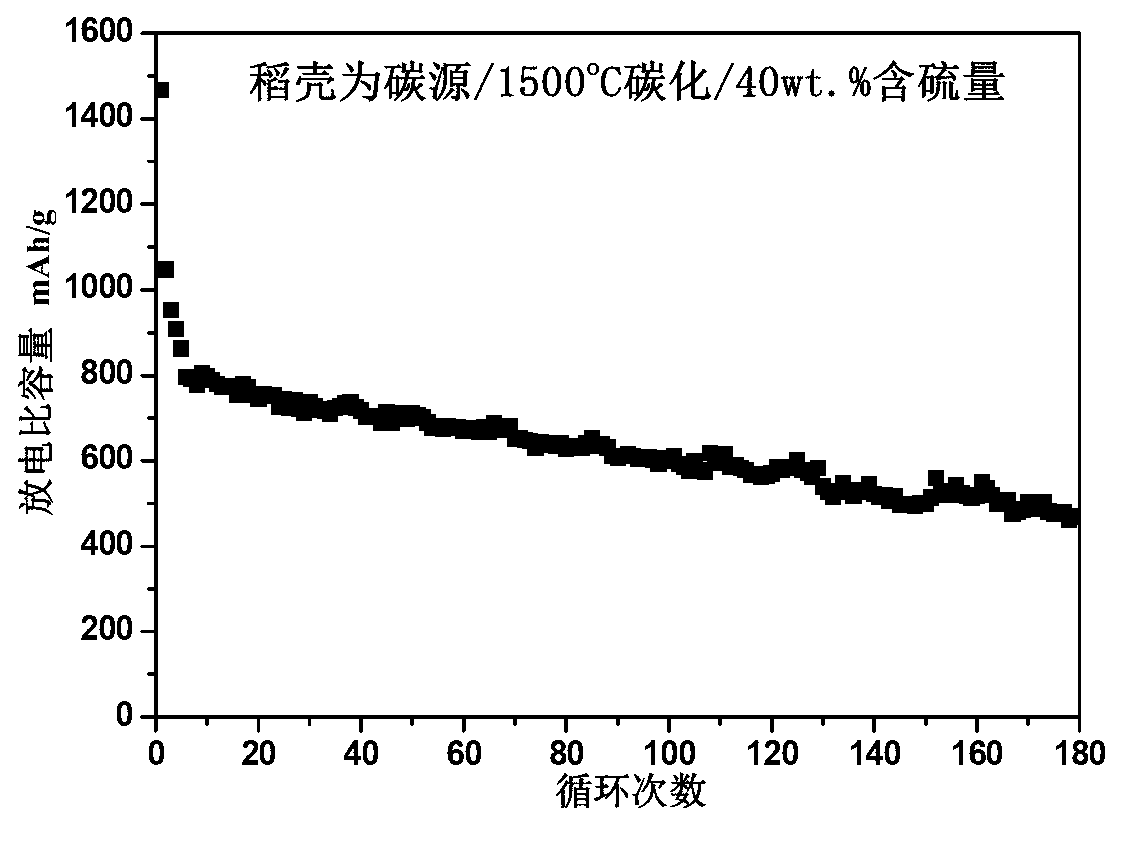

[0049] The washed and dried rice husks were kept at 600° C. for 10 hours under an argon atmosphere to carry out carbonization treatment. The cooled carbonized product was ball milled and stirred in 10 mol / L potassium hydroxide solution at 100°C for 0.5 hour to remove silicon oxide in the product. The solid washed with potassium hydroxide solution is further washed with water and then dried to obtain a carbon material, and the carbon material is further heated to 1500 ° C in a vacuum environment and kept for 1 hour to increase the crystallinity of the carbon material, thereby improving the carbon material. conductivity. The further calcined carbon material is cooled and mixed evenly with sulfur element according to the mass ratio of 3:2, and then the mixture is heated to 600°C for 2 hours in an argon atmosphere, and the sulfur / carbon composite material is obtained after cooling. The sulfur in the composite material The content is about 40% by mass.

[0050] Positive electrode...

Embodiment 3

[0054] The washed and dried rice husks are kept at 1100° C. for 1 hour under vacuum conditions for carbonization treatment. The cooled carbonized rice husk is ground and pulverized. The powder material was heated to 80°C with 5 mol / L sodium hydroxide solution and stirred for 2 hours to remove silicon oxides in the carbonized product. The carbon material is obtained after filtering the sodium hydroxide solution, and the carbon material is washed with water and then dried. Then, the carbon material is further heated to 1800° C. for 24 hours under a nitrogen atmosphere to increase the crystallinity of the carbon material. The further calcined carbon material and sulfur element are uniformly mixed according to the mass ratio of 3:2, the mixture is heated to 200°C under vacuum conditions, kept for 10 hours, and the sulfur / carbon composite material is obtained after cooling. The sulfur content in the composite material is about 40% by mass.

[0055] Positive plate preparation met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com