Method for preparing nano hydrated calcium silicate using silican fume as siliceous materials

A technology for hydrating calcium silicate hydrate and siliceous raw materials, applied in silicate, nanotechnology, alkaline earth metal silicate, etc., can solve the problem of large differences in structure and performance of calcium silicate hydrate and unstable raw material components , harsh reaction conditions and other problems, to achieve the effect of low price, easy operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

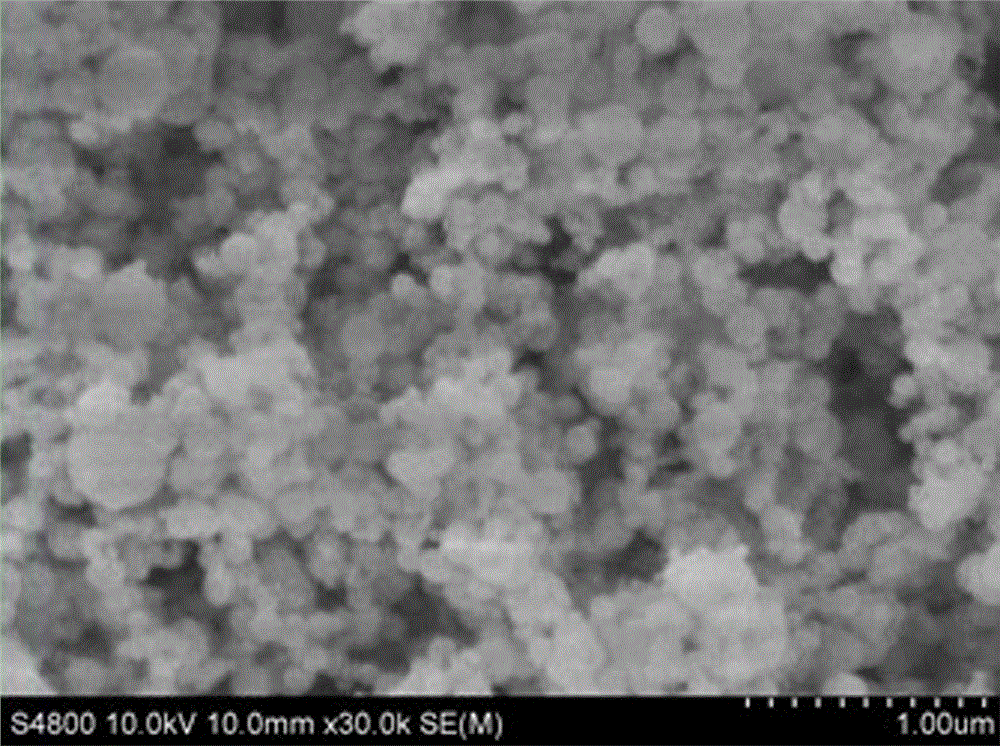

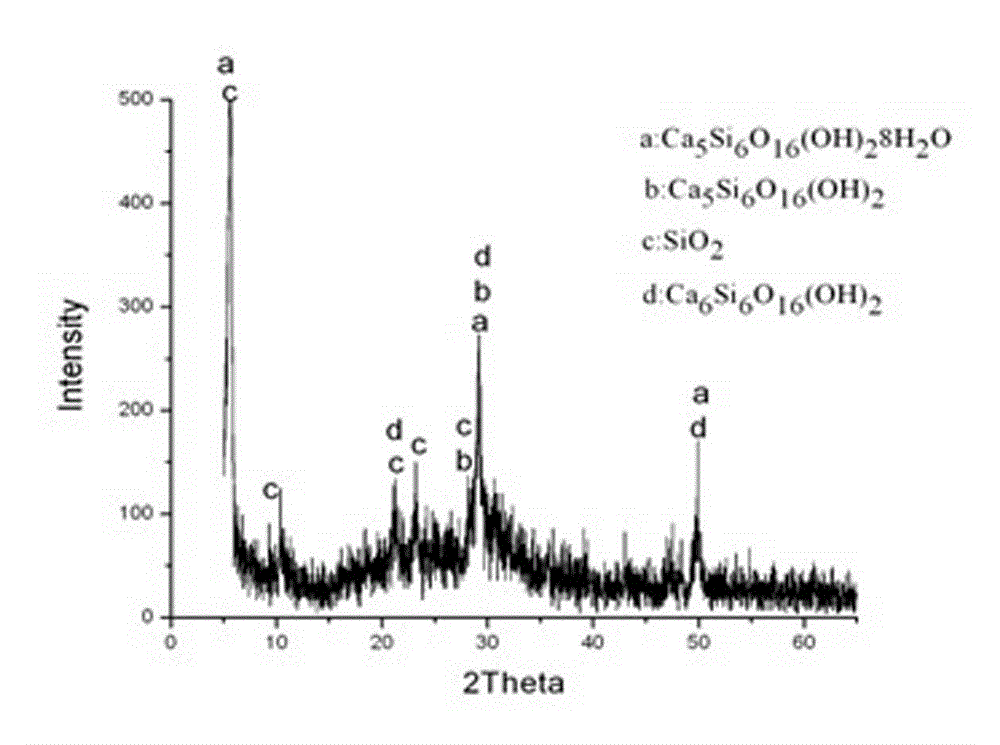

[0036] A preparation method of nano calcium silicate hydrate using silica fume as siliceous raw material, comprising the steps of:

[0037] (1) Take calcium oxide and silica fume and mix them evenly. Among them, the content of silica in silica fume accounts for 99%, so the mixing ratio of calcium oxide and silica fume is 1 according to the molar ratio of calcium oxide and silica fume. : The ratio of 2 is mixed evenly, and the amount of silica material is 99% of the actual mass of silica fume divided by the molar mass of silica; transfer the mixed raw materials into the reactor and add water, and the amount of water added is according to the water Add in a solid mass ratio of 30:1, add water and stir for 5 minutes, and finally react the mixed reactants in the reactor at 200°C for 9 hours;

[0038] (2) Wash the precipitated product obtained from the hydrothermal reaction in step (1) with water first, then treat it with ultrasonic waves for 6 minutes, then transfer it to a high-s...

Embodiment 2

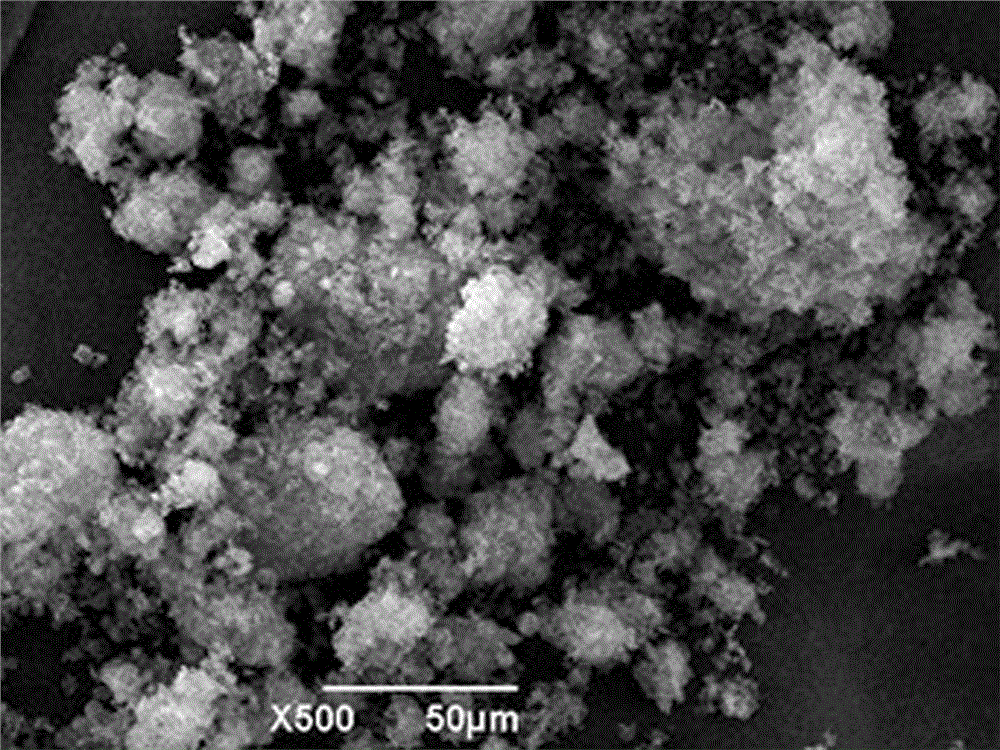

[0046] A preparation method of nano calcium silicate hydrate using silica fume as siliceous raw material, comprising the steps of:

[0047] (1) Take calcium oxide and silica fume and mix them evenly. Among them, the content of silica in silica fume accounts for 99%, so the mixing ratio of calcium oxide and silica fume is 4 according to the molar ratio of calcium oxide and silica fume. : Mix evenly in a ratio of 5, the amount of silica is 99% of the actual mass of silica fume divided by the molar mass of silica; transfer the mixed raw materials into the reactor and add water, the amount of water added is according to the Add in a solid mass ratio of 30:1, add water and stir for 7 minutes, and finally react the mixed reactants in the reactor at 120°C for 8 hours;

[0048] (2) Wash the precipitated product obtained from the hydrothermal reaction in step (1) with water first, then treat it with ultrasonic waves for 5 minutes, then transfer it to a high-speed centrifuge, and separa...

Embodiment 3

[0050] A preparation method of nano calcium silicate hydrate using silica fume as siliceous raw material, comprising the steps of:

[0051] (1) Take calcium oxide and silica fume and mix them evenly. Among them, the content of silica in silica fume accounts for 99%, so the mixing ratio of calcium oxide and silica fume is 1 according to the molar ratio of calcium oxide and silica fume. : Mix evenly in a ratio of 1, the amount of silica fume is 99% of the actual mass of silica fume divided by the molar mass of silica; transfer the mixed raw materials into the reaction kettle and add water, the amount of water added is based on water Add in a solid mass ratio of 30:1, add water and stir for 6 minutes, and finally react the mixed reactants in the reactor at 140°C for 6 hours;

[0052] (2) Wash the precipitated product obtained from the hydrothermal reaction in step (1) with water first, then treat it with ultrasonic waves for 6 minutes, then transfer it to a high-speed centrifuge,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com